Harnessing the power of cable assemblies and wire

By Staff Report August 9, 2024 5:51 pm IST

Cable assemblies and wire harnesses are essential in various industries. They offer robust exterior coatings, improved wire bundle protection, and efficient electrical system organisation.

Despite their frequent interchangeable usage, cable assemblies and wire harnesses are essential components in electrical engineering and communication. They are designed for electrical current routing in particular locations and are used in communication and electrical engineering.

While cable assemblies and wire harnesses aim for the common objective of routing electricity, their operational characteristics and intended purposes show substantial differences. Understanding these differences is vital for successful manufacturing processes requiring component selection based on requirements.

This comprehensive discourse delves into the intricate nuances between wire harnesses and cable assemblies, providing an understanding of various components and enabling informed decisions on their selection and utilisation across applications.

Cable assembly

A cable assembly is a device that combines conductors like wires or cables into a unified sleeve, often terminated with a plug or connector. It is coated in vinyl or thermoplastic to streamline navigation around obstacles and serve specific functions in electronic applications like LED-lighted clothing, flat panel displays, cockpit systems, accessories, and costumes.

Wire Harness

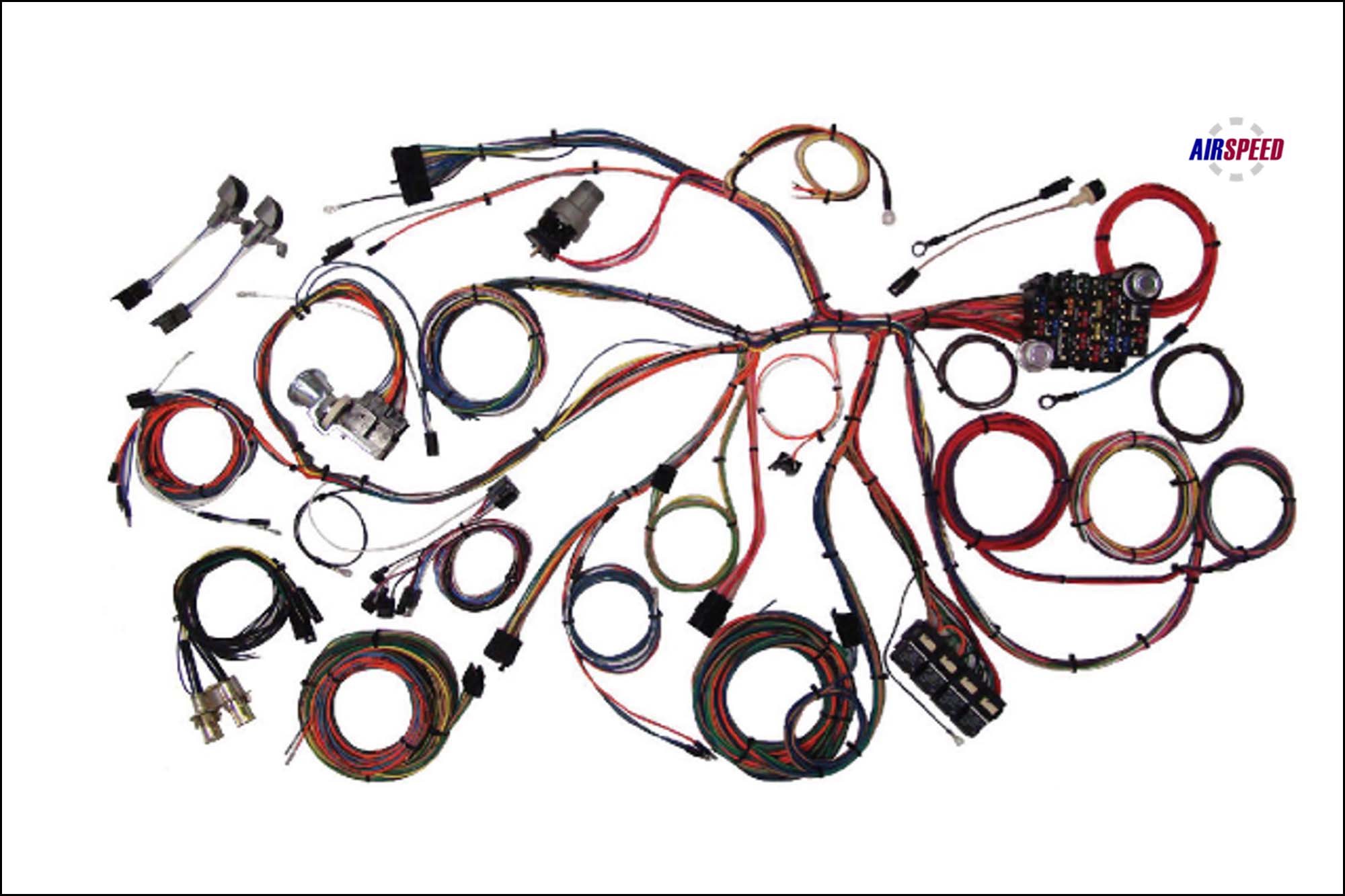

Wire Harness consolidates multiple cable assemblies into a structured configuration, protecting wires from environmental adversities like heat, friction, and moisture through protective sleeves or ties. This protective measure shields the cables and simplifies the routing process within intricate systems, facilitating seamless design and breakout.

Applications and utilisation

The cable assembly applications and wire harnesses span a broad spectrum of industries and functionalities, each serving distinct purposes tailored to specific requirements.

Automotive wire harnesses are used in the dash and the hood. Refrigerator harnesses are deployed for appliance functionality.

Benefits

Robust exterior coatings of cable assembly are resistant to environmental elements, proving ideal for outdoor applications. They improve wire bundle protection against environmental stressors. Cable assembly leads to efficient electrical system organisation for simplified maintenance and handling.

Wire harnesses offer improved connectivity and system management through organised cable assembly. They are suitable for indoor applications with protected casings and are cost-effective compared to cable assemblies.

The wire harness has a loading capacity limit, which is a factor of the size and number of cables bundled. It is suitable for indoor applications but cannot withstand elements like dust, heat, moisture, and friction.

The technological differences between wire harnesses and cable assemblies determine their functionality and applications across industries. By understanding their complexities, engineers can make more educated decisions about these components in various projects.

Courtesy: Airspeed Manufacturing Vietnam

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.