Efficient welding with minimum programming effort with CLOOS

By OEM Update Editorial August 13, 2020 6:53 pm IST

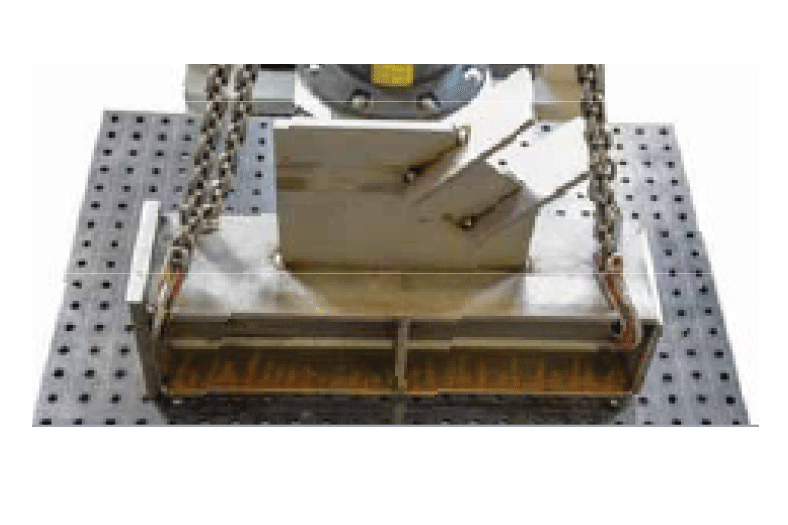

IRPS Instant Robot Programming System

Do you wish to weld the smallest batch sizes efficiently and through automation? Particularly in steel and metal construction, the programming effort for automated welding of small batch sizes is often disproportionally high. Use the IRPS Instant Robot Programming System to create programmes for automated welding in a short time. So the automated welding of workpieces in batch size 1 pays off now.

Overview of the IRPS benefits:

Minimum programming effort

- Enormous time saving

- Increase of the system efficiency

- CAD workplace not necessary

Recognising position and tolerances of the workpiece

- Excellent weld quality

- Time saving as re-teaching is not necessary

Reduction/absence of the clamping device

- Reducing the investment costs

- Minimising of non-productive times

Shortening of planning times

- Just-in-time production

- Reduced personnel and material binding

- Quick delivery periods

-

- Flexible use of personnel and minimum training expenditure

- Knowledge of robot programming and welding not necessary

- With the IRPS functions, you can process the generated 3D data of the workpiece on the screen simply and intuitively:

- Weld length

- Weld direction

- Welding order

- Angle and distance of the torch to the weld

- Changes of the welding parameters

- Set tack points

- Insert tactile 2D search runs

- Create paths for multi-layer welding

Intuitive operation

Check and change

For more details, visit: www.cloos.de

E-mail: info@cloos.de

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.