Jet aeration power efficient water purification

By Staff Report September 10, 2024 11:51 am IST

Jet aeration systems offer an efficient and low-maintenance solution for wastewater treatment. They enhance oxygen transfer and, via mixing, improve water quality in STP and ETP applications.

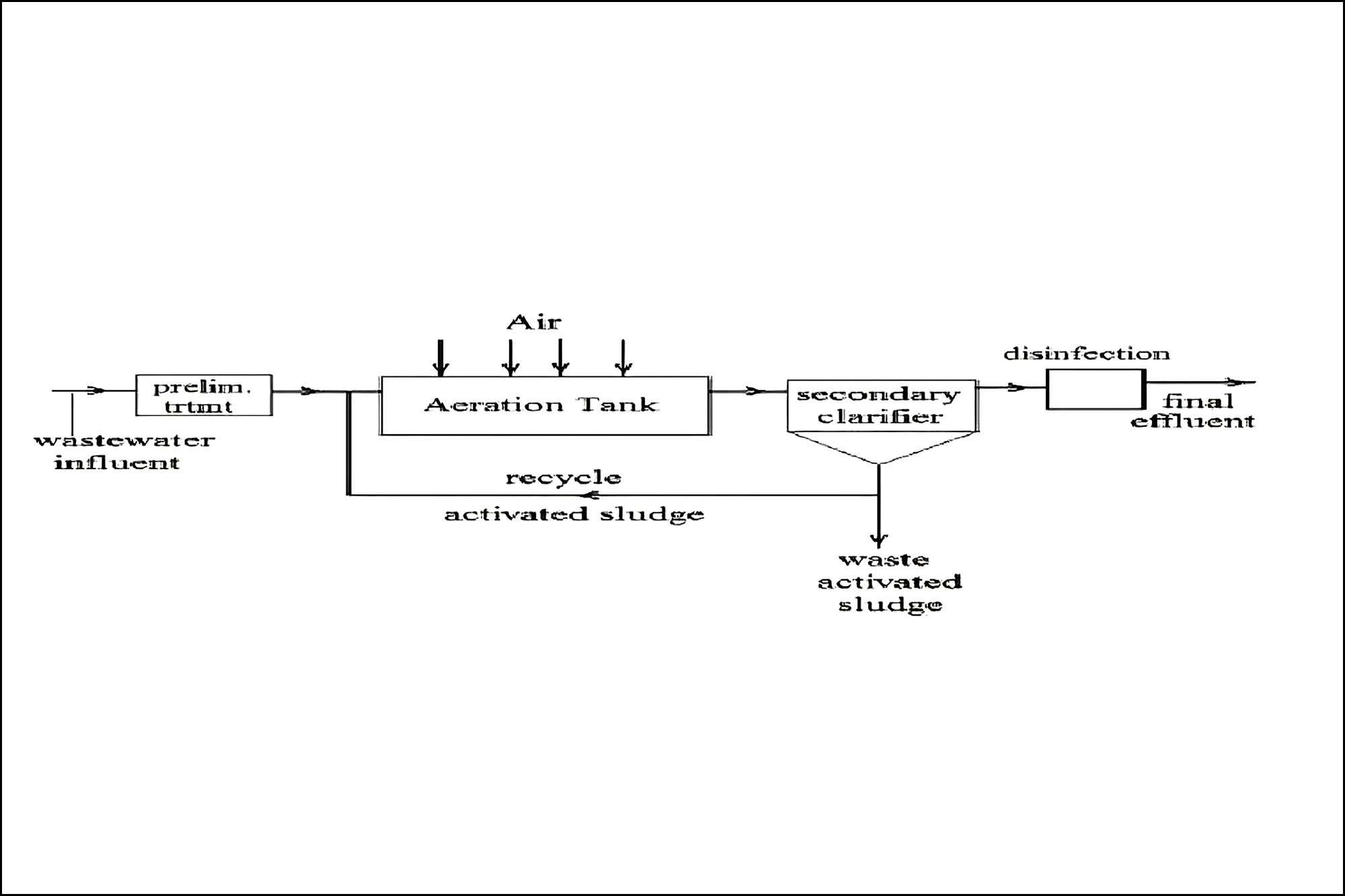

Hydraulic retention time (HRT) and aeration are crucial in wastewater treatment, particularly in biological treatment systems. HRT is the time it takes for water to pass through a treatment system, providing sufficient contact time for microbial processes. By controlling the HRT, treatment plant operators can optimise the efficiency of their systems and ensure that pollutants are removed.

Aeration is utilised in sewage treatment plants (STP) and industrial effluent treatment plants (ETP). Aeration involves injecting air or oxygen into the wastewater to promote the growth of aerobic bacteria, which consume organic matter and other pollutants in the water. This process helps break down contaminants and reduce the water’s chemical oxygen demand (COD), making it safer to discharge back into the environment. Aeration maintains the efficiency and effectiveness of the treatment plant, as it plays a key role in the biological treatment of wastewater.

Aeration Systems

The most popular are surface aeration (mechanical) and diffused aeration (coarse, medium, fine-bubble). In STP/ETP wastewater plants, aeration is typically achieved through mechanical aerators, diffused aeration systems, or surface aerators. Mechanical aerators consist of rotating paddles or propellers that agitate and introduce air into the water. Diffused aeration systems use air stones or diffusers to release air bubbles into the water, while surface aerators create turbulence at the water’s surface to increase oxygen transfer.

2.1. Surface Aeration

The blades that create turbulence on the liquid surface in the activated sludge method are an important element of these devices. Rotating blades, rotors or brushes are used in certain biological contact oxidation ditches. Creating a turbulent flow enhances aeration, facilitating the biological processes in wastewater. Currently, such solutions are rarely employed, only during the modernisation of the treatment plants with shallow tanks (depth up to 3.5 m).

Oxygen transfer efficiency for surface aerators is about 0.5 kg O2/kw hr.

2.2. Diffused Aeration

Aeration using blowers is the predominant solution in practical applications due to their availability, efficiency, and reliability; therefore, this method remains the focus of the present work.

The air compressed by blowers is transmitted through pipes to diffusers, which are elements typically located near the bottom of a biological reactor that introduces the air into the wastewater. The size of air bubbles plays a key role in this method. It was observed on numerous occasions that the size of the bubbles determines how much oxygen transfers to the wastewater as the bubbles rise towards the surface. The smaller a bubble released from a diffuser, the slower it will rise to the surface and the longer it will remain in the wastewater; therefore, it will have more time to transfer oxygen in greater amounts. Thus, fine-bubble diffused aeration (d < 3 mm bubbles) has become standardised in municipal wastewater treatment plants.

Oxygen transfer efficiency for diffused aerators is about 18 kg O2/kWh.

2.2.1. Diffuser Fouling

Diffuser fouling reduces oxygen transfer efficiency and increases pressure losses in the network. Consequently, this leads to higher energy consumption in the aeration process and negatively impacts the stability of the wastewater treatment process.

Diffuser fouling can be attributed to several factors. Fibrous substances and organic and inorganic materials can infiltrate the diffuser pores due to inadequate airflow. Oils, greases, and fats contribute to fouling, as do precipitated substances like iron compounds and carbonates. The biofilm growth on the diffuser material exacerbates the problem, trapping additional organic and inorganic substances. Particulate matter from inadequately purified air, oil leaks from blowers, and corrosion residues from corroding pipes supplying compressed air also play a role. Furthermore, pollutants in wastewater can infiltrate the pipe with compressed air through damaged diffusers or cracked pipes, compounding the issue.

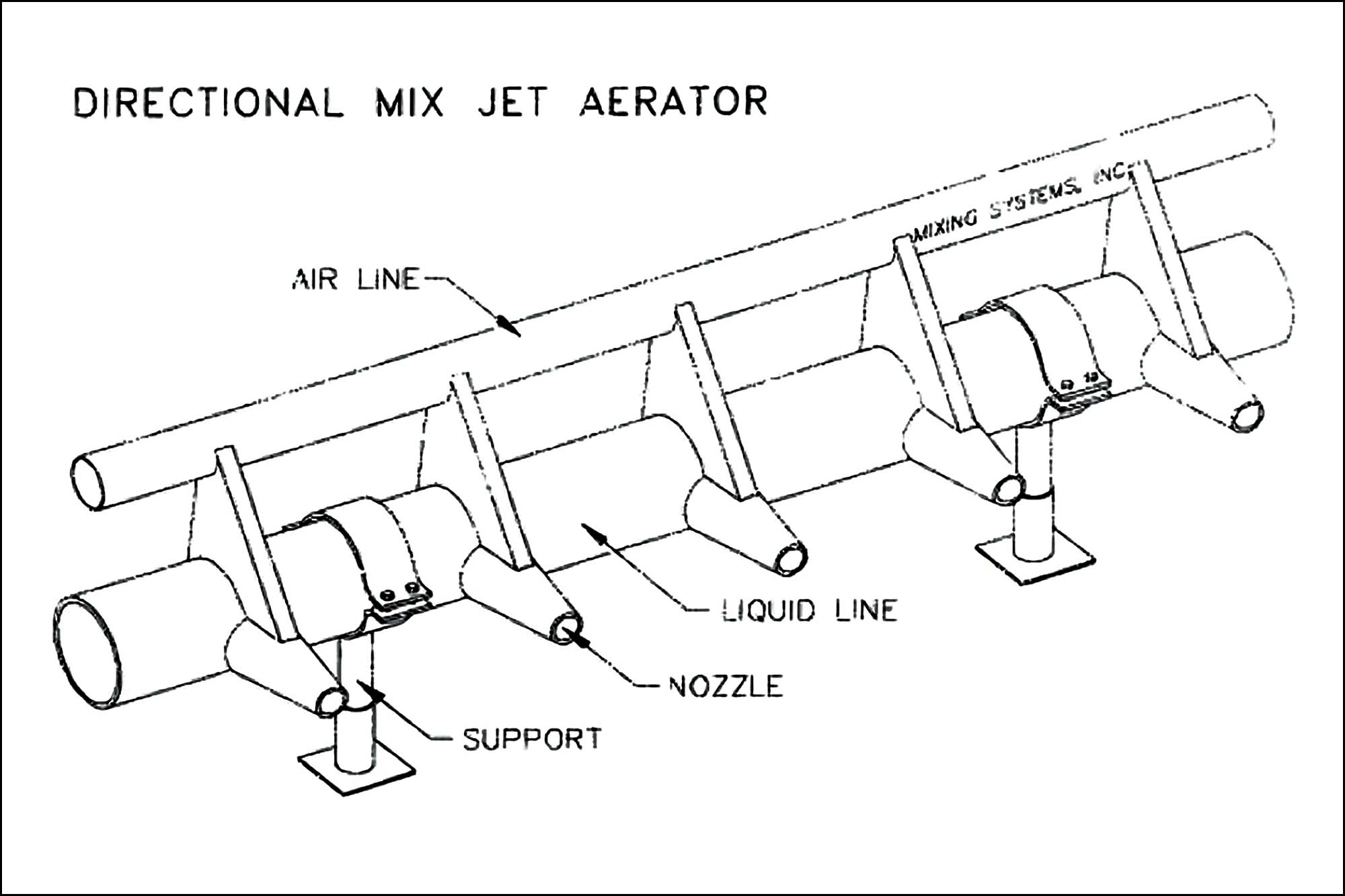

2.3. Jet Aeration

Jet aerators use the ejector method for contacting gases and liquids. The jet consists of a double nozzle arrangement that includes a primary inner nozzle with an intermediate high-shear mixing chamber, which circulates the water, and an outer secondary nozzle that draws in atmospheric air perpendicularly with high velocity. Intense contacting and mixing of the two streams (water and air) occurs in the high-shear mixing chamber—the intimate contact between gas and liquid streams results in micron-sized bubbles. The fine bubble gas/liquid mist is jetted out through the divergent nozzle into the main tank.

The plume’s horizontal travel maintains high-pressure conditions for a longer time than conventional diffused air systems. This high-pressure condition gives the gas bubbles a greater opportunity to dissolve in the liquid, increasing the oxygen transfer efficiency.The plume’s injection into the tank volume provides mixing energy. The plume’s movement creates fine eddy currents in the surrounding liquid, thoroughly mixing the tank and keeping the MLSS solids in suspension. To enhance mixing and solids suspension, high-velocity gradients are established in the mixing tank. These velocity gradients are random, which helps produce liquid homogeneity and solids suspension.

When the plume’s initial horizontal momentum dissipates, it rises to the top of the liquid surface, producing an air lift effect that further mixes the tank contents. The jet plume also creates effective molecular dispersion, and such intimate mixing of reactants ensures effective process operation.

The aeration process may consume 50% to 90% of the electricity used for a wastewater treatment plant, while the cost of consumed power may constitute as much as 15–49% of the plant’s total operation costs. This scenario drives STP/ETP managing organisations to implement optimization solutions to reduce the cost of these energy-intensive processes.

Given the key role of biological decomposition of organic compounds, microorganisms, mainly bacteria, that process organic compounds into gaseous end products and water must be supplied with an appropriate amount of oxygen.

Oxygen transfer efficiency for Jet aerators is about 21.53 kg O2/kWh.

Case Study

At a plant in Bhandup, Maharashtra, Adira Water encountered a challenge with operating and maintaining the STP (100KLD STP Project). Due to an incompatible plant design, the wastewater in the clarifier was stagnant for more than 8-10 hours. The clarifier tank lacked a connection to the blowers or aeration system, resulting in a foul smell and yellowish effluent colour. This insufficient aeration impacted the nitrification and denitrification process, leading to an unpleasant effluent appearance.

Upon assuming responsibility for the project’s operation and maintenance, the primary goal was to eliminate the foul smell and unpleasant colour through a complete nitric-denitrification process. However, the existing project had GI pipe fittings that posed an obstacle to rerouting the aeration line within a reasonable budget. Adira Water opted for extended aeration to enhance performance with minimal modifications to the existing line. By implementing a Jet Aeration system, Adira Water achieved cost-effective results and improved water quality in colour and odour. The treated wastewater, previously unused due to its unpleasant smell, is now fully utilised for gardening and cleaning.

Advantages of Jet aeration over other Aeration Systems

Jet aeration systems offer several advantages over other aeration methods, including superior energy efficiency, as they consume less power than diffused and surface aeration systems. They also require low maintenance due to durable, abrasion-resistant, and corrosion-resistant materials; the jet nozzles have no moving parts to wear out or small passages to clog. With pumps and blowers typically located outside the tanks for easy servicing, these systems reduce installation labour. Additionally, jet aerators provide operational flexibility, allowing mixing through recirculation pumps and adjusting oxygen transfer rates by varying airflow to match process conditions, resulting in power savings.

Conclusion

Jet aeration is used in wastewater treatment for municipal and industrial influent. The Venturi jet aerator, which operates on the ejector principle, is a highly effective solution for wastewater treatment plants. This technology offers a cost-effective method for optimal mixing and aeration in various applications, such as wastewater treatment plants and stormwater retention tanks.

One key advantage of the Venturi jet aerator is its ease of installation. It can be installed as a stand-alone unit. This aerator reduces odour and septic conditions, creating a sanitary environment.

Another benefit of the Venturi jet aerator is its self-aspirating design, eliminating the need for compressed air. This feature reduces costs and provides consistent performance regardless of water level fluctuations. It operates quietly without generating aerosols or causing sedimentation on the tank bottom.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.