Oxy-fuel technology delivers superior precision

By OEM Update Editorial June 17, 2024 6:03 pm IST

Arun Jain, Head – Oxyfuel Business at Messer Cutting Systems, discusses the significance of oxy-fuel technology in the metal cutting industry. Messer Cutting Systems offers a range of oxy-fuel products to enhance productivity, efficiency, and precision. Raut highlights the benefits of oxy-fuel technology and why Messer Cutting Systems is the preferred choice.

Messer Cutting Systems’ oxy-fuel technology utilises oxyacetylene and oxy-LPG – a powerful fuel combination with exceptional cutting, heating, and brazing capabilities. This gas combination allows precise cuts across various material thicknesses, making it a versatile choice for different industrial applications.

Potential of Oxy-fuel technology

With Messer Cutting Systems’ oxy-fuel products, businesses can achieve clean, high-quality jobs with unparalleled speed and accuracy.

Messer Cutting Systems and gas-cutting torches are crafted and designed for exceptional performance, precision, and safety. With advanced features like a high-flow design and multiple pre-heating options, they ensure smooth cuts in demanding environments. The ergonomic design and optimal weight distribution make them easy to use, reducing operator fatigue and increasing productivity. These torches can be used with oxyacetylene and oxy-LPG combinations.

In the present technologically driven environment, automation is critical for simplifying processes and increasing efficiency. Messer Cutting Systems’ oxy-fuel solutions work perfectly with CNC (Computer Numerical Control) systems, allowing businesses to automate their cutting processes with precision and efficiency. CNC integration reduces human error and provides uniform, repeatable cuts, increasing output while minimising material waste.

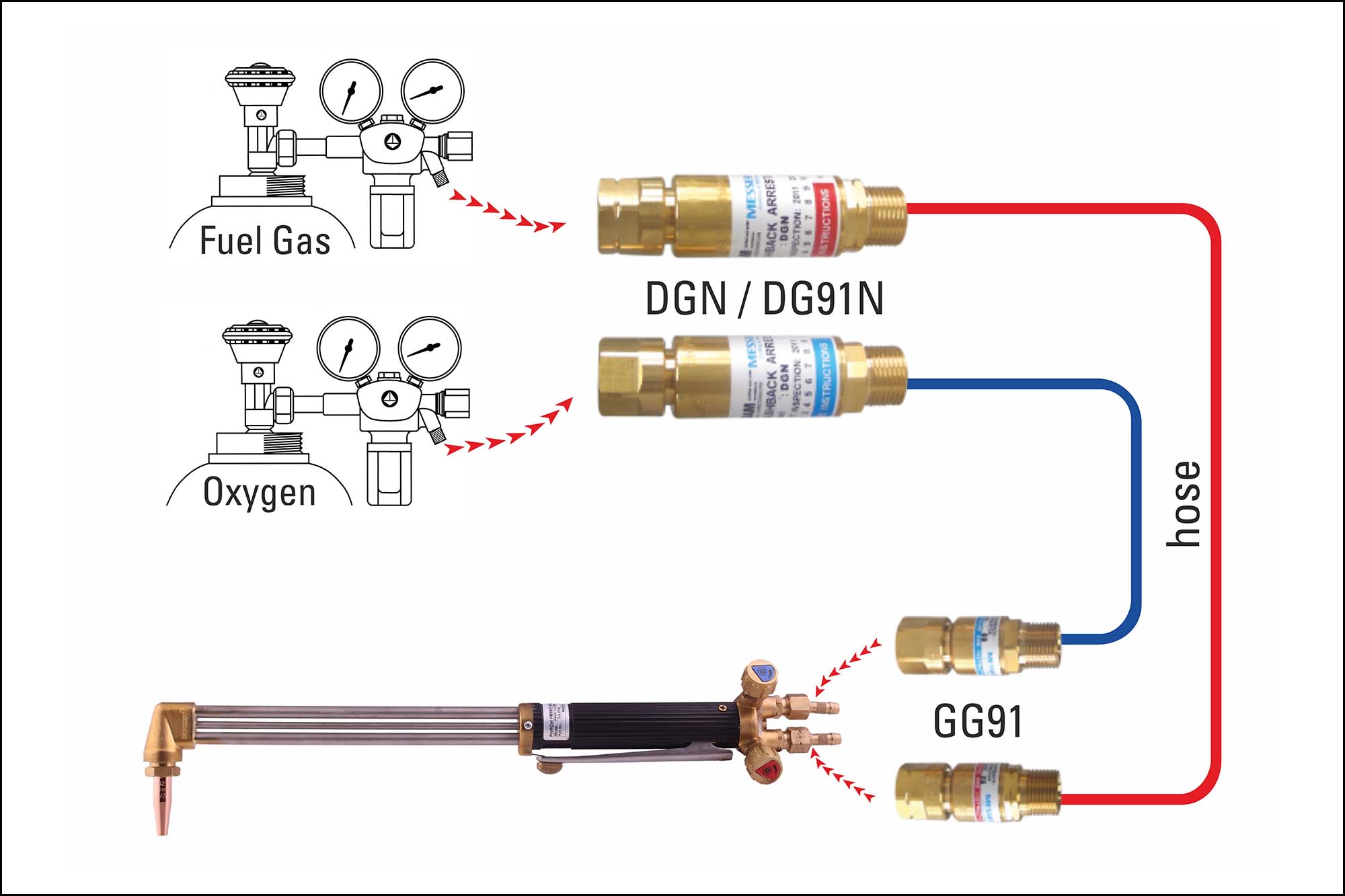

Messer Cutting Systems pressure regulators are essential for the precision control of gas flow and pressure, enabling operators to fine-tune the cutting process according to specific requirements. These regulators, with their exceptional stability and durability, ensure consistent gas flow, resulting in uniform cuts and minimal rework.

Flashback Arrestors prioritise safety in every industrial setting, such as when safety comes first, and Messer Cutting Systems understands how important that is. The highest quality standards are used for constructing Messer flashback arrestors, which defend against potentially hazardous flashback events. These arrestors protect people, machinery, and the working environment by stopping flames from spreading into the gas supply system.

Messer provides a variety of oxy-fuel gas brazing torches, including the feather-light Minitherm torch. This torch is highly sought after due to its low weight, increased productivity, and easy manoeuvrability, making it suitable for oxyacetylene and oxy-LPG combinations.

Messer offers a range of heating torches for various flame-heating applications in the industry, including pre-heating, post-heating, bending, straightening, and more. Customers can choose from standard torches or customised solutions. These torches can operate with various gas combinations, including oxy-LPG, oxyacetylene, fuel gas with compressed air, and only LPG.

Messer provides gas savers for shielding gasses in MIG/MAG applications and oxy-fuel gas economisers for brazing stations, highlighting the importance of saving in today’s competitive business environment.

Conclusion

Oxy-fuel technology from Messer Cutting Systems provides businesses with the precision, efficiency, and safety necessary to succeed in the metal cutting, heating, and brazing industries. Their extensive product line includes oxyacetylene, gas-cutting torches, pressure regulators, and flashback arrestors and offers unsurpassed cutting capability for a wide range of applications. Businesses that embrace Messer Cutting Systems oxy-fuel technology realise their full potential, obtain superior cutting outcomes, and remain ahead of the competition.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.