A bioengineered breakthrough for taming high-salinity wastewater

By Staff Report August 9, 2024 7:09 pm IST

HaloSol is a bioengineered microbial consortium designed to treat high-salinity industrial wastewater. It reduces COD/BOD, complying with environmental regulations while lowering costs and carbon emissions.

Industrial activity is the backbone of modern civilisation but comes at a cost. Millions of tons of polluted wastewater are discharged from factories worldwide every year. These industrial wastewaters contain a complex cocktail of contaminants, posing a significant threat to human health and the environment.

A staggering 2 billion people still lack access to safe sanitation, and polluted water is a major culprit behind waterborne diseases like cholera, typhoid, dysentery and many types of cancer. Industrial pollutants also disrupt aquatic ecosystems, harm wildlife, and contaminate drinking water sources.

The numbers don’t lie

A 2020 UN report warns that water pollution costs the global economy $6.7 trillion annually. According to a UNESCO report, 80 percent of wastewater goes untreated, polluting rivers, lakes, and oceans. It is a statistic that paints a grim picture of the impact on our water resources.

The consequences of untreated industrial wastewater are far-reaching. Contaminants like heavy metals, organic pollutants, and toxic chemicals can leach into the soil and groundwater, making drinking unsafe. These stark statistics reveal the severity of the wastewater crisis, demanding immediate action through effective treatment methods.

The high COD/high TDS challenge

Treating industrial wastewater is challenging. A particularly troublesome category of wastewater is highly saline effluent. This type of wastewater is a double threat, containing both significant organic pollutants (indicated by chemical oxygen demand (COD) and biological oxygen demand (BOD)) and a very high total dissolved solids (TDS) concentration exceeding 10% (or 100,000 mg/l). COD indicates the amount of organic matter present, which can deplete oxygen levels in water bodies and harm aquatic life.

Traditional treatment methods struggle to effectively reduce the COD and TDS levels, especially when TDS exceeds 10% (1,00,000 mg/l). For instance, biological treatment processes, which rely on microbes to break down organic pollutants, become inhibited by excessive salt concentrations. This leaves industries with limited options, often resorting to expensive and energy-intensive solutions like evaporation that also contribute to greenhouse gas emissions.

Introducing HaloSol: A microbial marvel

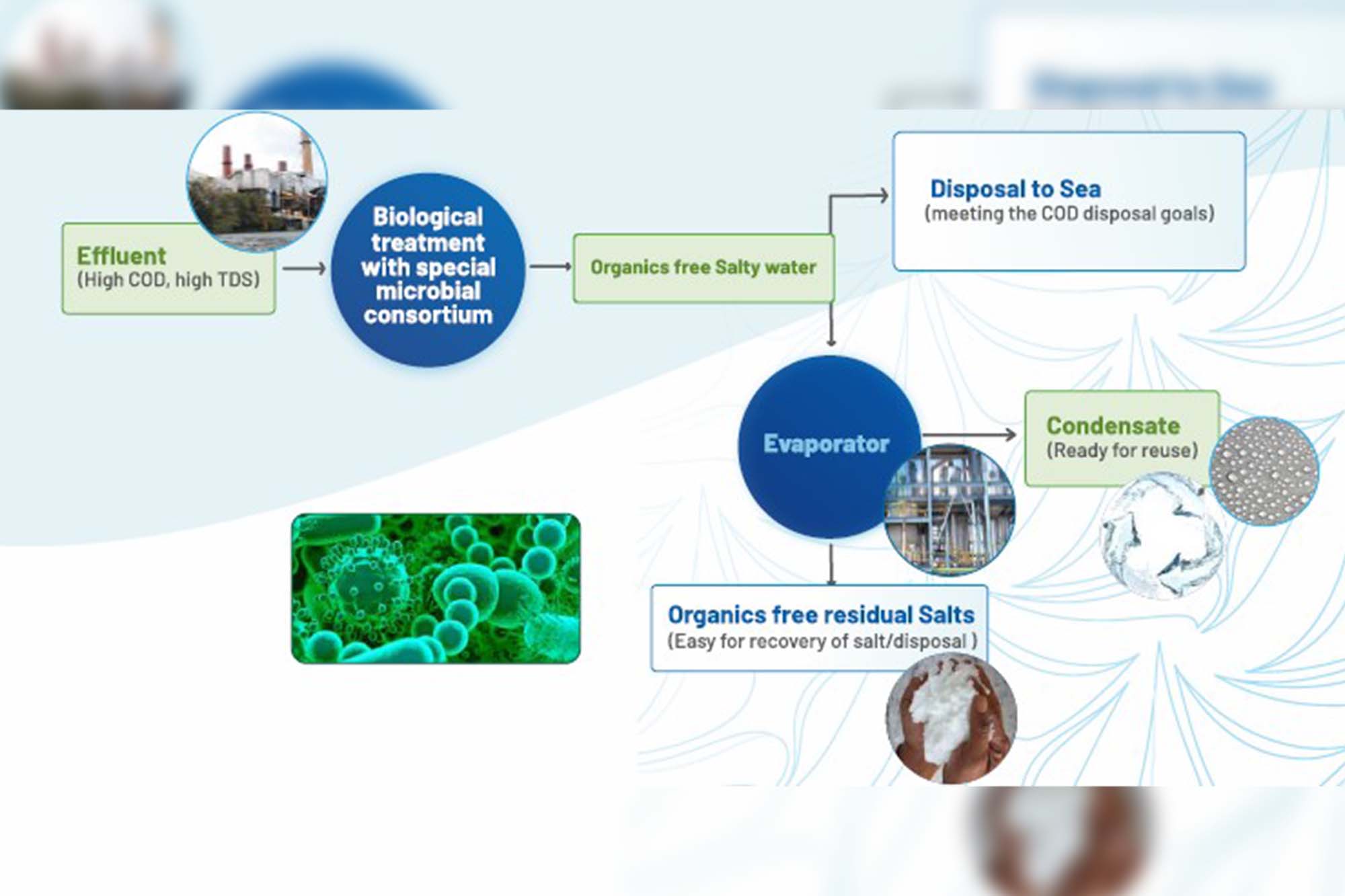

Praj Industries has tackled this challenge with HaloSol, a bioengineered microbial consortium. This innovative solution reduces the organic contents (COD/BOD) from salty effluent with TDS more than 10% (1,00,000 mg/l).

HaloSol’s secret lies in its specially engineered microbial community. These specially selected microbes are adept at thriving in high-salt environments and breaking down organic pollutants (COD/BOD) even in the presence of high TDS.Halosol can treat such wastewater for disposal into the sea (if permitted) or pre-treatment before an evaporator. This prevents the carryover of organics into the condensate, thereby rendering it free for reuse without undergoing condensate treatment.

Benefits

The benefits of Halosol extend far beyond effective wastewater treatment:

- Reduced costs: By eliminating the need for evaporators or condensate treatment, Halosol significantly reduces capital expenditure (CAPEX) and operational expenditure (OPEX).

- Environmental sustainability: The reduced energy consumption associated with Halosol translates to lower carbon emissions, making it a greener and more eco-friendly solution.

- Maximum efficiency: Halosol removes COD and BOD (biological oxygen demand) from wastewater, ensuring compliance with environmental regulations.

- Tailored treatment: Praj Industries recognises the diverse nature of industrial wastewater. They can bioengineer Halosol to suit specific client requirements, ensuring optimal performance for various industries.

Applications

The versatility of Halosol makes it a valuable tool for a wide range of industries:

- Chemical industry: Effectively treat wastewater containing organic pollutants and salts.

- Textile industry: Degrade dyes and other organic contaminants present in textile wastewater.

- Pharmaceutical industry: Biologically reduce complex and highly concentrated organics from pharmaceutical wastewater.

- Brine treatment: Remove organic contaminants from brine solutions.

A sustainable future

HaloSol represents a breakthrough in high COD/high TDS industrial wastewater treatment. Through innovative bioengineering, Praj has a groundbreaking solution that effectively tackles the challenge and proves cost-effective and environmentally responsible. As industries worldwide seek greener and more sustainable practices, solutions like HaloSol will play a crucial role in shaping our sustainable future.

Note:

Praj Industries can bio-engineer a special microbial consortium to suit specific requirements. Although HaloSol has the potential to be used at field scale, pilot plant trials are recommended at the client site before full-scale implementation. This is essential as the nature of COD and TDS can greatly vary depending on the products being manufactured.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.