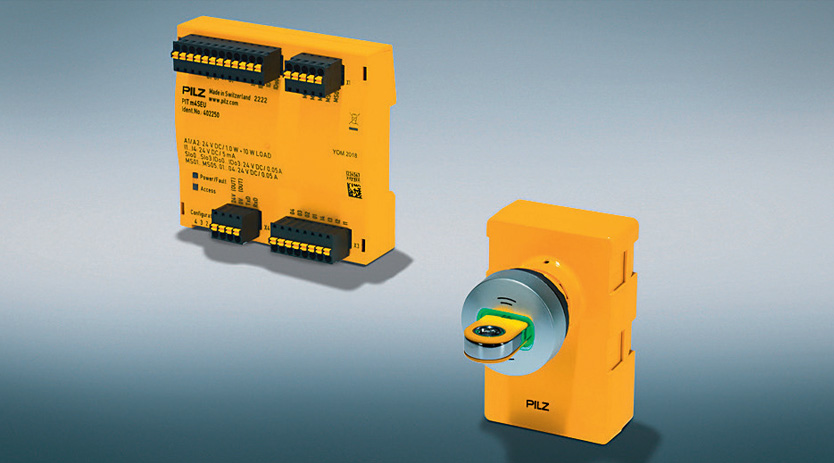

Smart Operating: Combining safety and security in a unified mode selection and access permission system

By OEM Update Editorial May 16, 2023 5:59 pm IST

They have long been part of our daily lives: smartphones, which are operated intuitively without the need for instructions, and smart building automation, which is operated via an app while you are on the move. These technologies are used as a matter of course and support people. It’s logical, then, that the call for more usability in engineering is getting louder.

Plants are getting more sophisticated in their operations, incorporating interconnectivity between plants and machinery to create modular systems that are essential for future factories. Mobile applications are also critical components of these systems. Other necessary features include the ability to conduct remote maintenance, especially for mobile machines, and access to production and diagnostic data. Despite the complexity, the setup and operation of these systems should be straightforward and self-explanatory. This challenges secure machine communication, but user-centric operating concepts can provide a solution.

Challenge: safe and user-friendly

To ensure functional safety, an operating concept must prioritise user-friendliness. When a safety device becomes overly complicated, there is a risk that it will be tampered with and rendered ineffective. Therefore, customised solutions that are purpose-built and tailored to the specific application are necessary. The operating concept must be easy to understand, with a clear and intuitive design. This reduces the training required for machine operators, preventing misuse and minimising downtimes.

Touchscreen operation

The operating concept will incorporate operator terminals, such as the Pilz Machine Interfaces (PMI), which provide all the necessary functions to create ergonomic user interfaces and web-based visualisation solutions, like PASvisu. By closely collaborating with the controller and visualisation, users can enjoy easy plant operation while benefiting from monitoring and diagnostic features. To achieve this, the operator terminals must be seamlessly integrated into the machine design, as users must have a comprehensive view of their application at all times. Therefore, PMI touchscreen panels are available in various sizes and designs, making them ideal for integration into different environments. Customers who use their software can combine it with the PMIopen, an open hardware platform.

Visualisation with PASvisu

The PMIvisu operator terminals can be accessed through PASvisu, which uses HTML5, making it platform-independent. This means that nearly any end device, such as a PC, tablet, or smartphone, can be used to access it in the respective web browser. This allows for remote maintenance based on Client-Server functionality and ultimately reduces downtimes. Additionally, this solution can be used to create mobile applications. PASvisu provides all the expected human-machine interface (HMI) functions in modern visualisation software.

Diagnostics and maintenance are evolving to become more user-friendly and predictive. An example is the PSENmlock safety gate system, which now has a version suitable for series connection and can be used in stand-alone machines up to large-scale interconnected plants. When combined with the Pilz diagnostic solution Safety Device Diagnostics (SDD), gates can be connected through a one-cable solution and controlled individually. Unlike other systems, this innovative diagnostic solution can cover 900 meters, enabling the connection of large high bay racking systems through a single cable solution. All sensors are centrally managed through a fieldbus module on the diagnostic system, making the wiring more user-friendly and opening up new diagnostics and maintenance possibilities. SDD can retrieve status information from connected safety gate sensors, read configuration parameters, and visualise actions. If a sensor is faulty, users can quickly locate and rectify the issue.

Centralised data management

Intelligent diagnostic solutions offer extensive data on the status of safety devices. Smart diagnostics provide predictive data on maintenance and sensor replacement and display past data. This results in shorter downtimes and increased productivity. The greater the data available, the more precise the diagnostics become. Clear presentation and simple evaluation are crucial to ensure users maintain an overview. Cloud solutions are increasingly popular, allowing for centralised data storage and remote access from anywhere worldwide. Remote maintenance has become an essential component of modern automation solutions.

Paving the way for “machine learning.”

However, smart operating concepts for Industrie 4.0 are far from exhausting the possibilities. In future, IIoT (Industrial Internet of Things) Gateways will contribute towards the further networking of plants and machinery. User management will be coupled with operator panels. It will be possible to operate touchscreen panels with gestures, similar to smartphones, and operators can teach robots via hand guiding. Virtual reality, on the other hand, opens up a whole new range of possibilities for modern machine training or remote maintenance.

However: at the centre of the new operating concepts is always the human, supported by intelligent technologies.

For more info contact Pilz India Pvt. Ltd.

www.pilz.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.