SLTL pioneering precision in laser technology for i4.0 excellence

By OEM Update Editorial January 18, 2024 12:06 pm IST

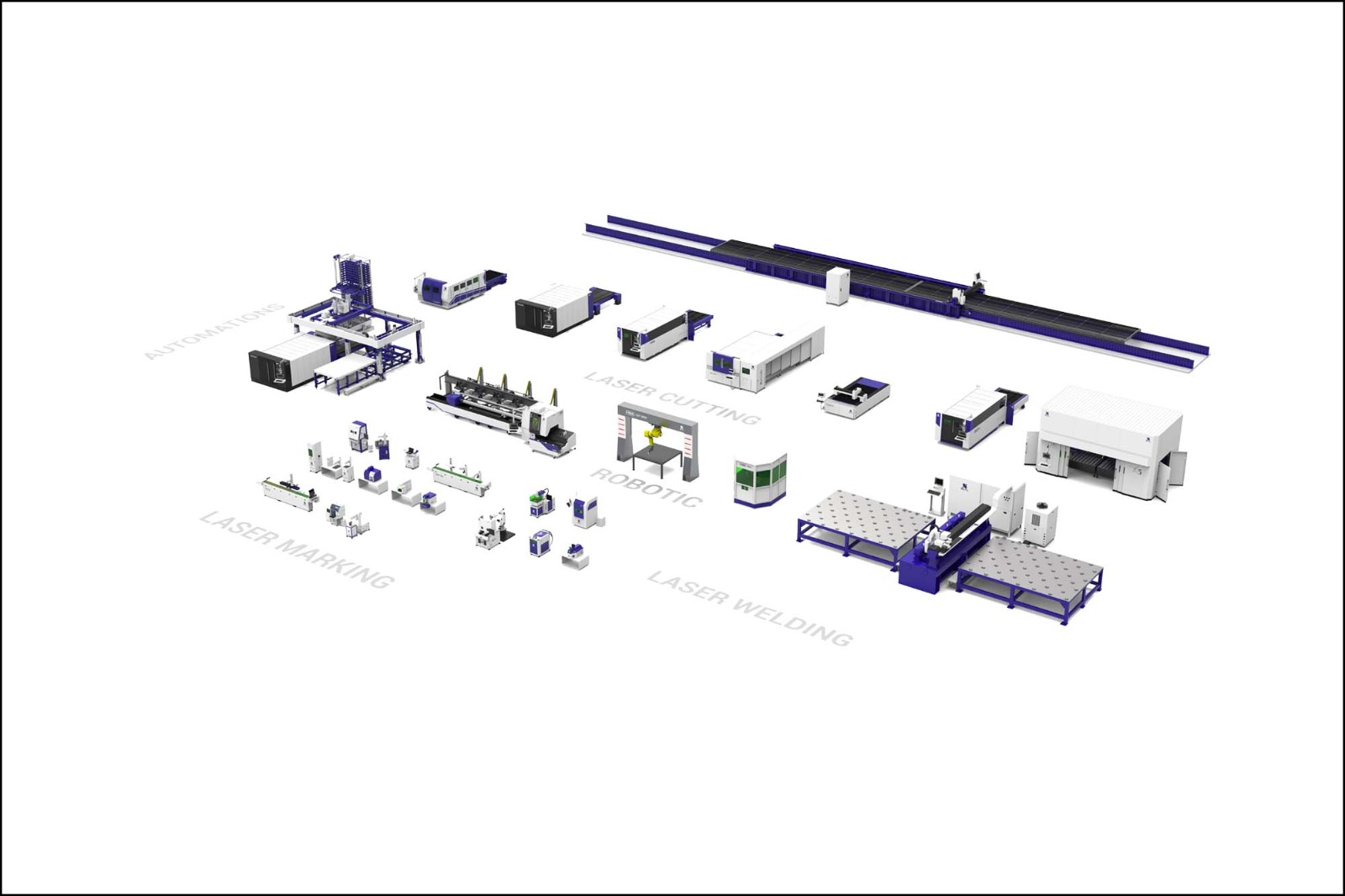

Experience manufacturing’s future with SLTL Group, a laser technology pioneer. With 25,000+ installations worldwide, SLTL redefines precision with ultra-high-power cutting, innovative tube automation, 5-axis flexibility, and Industry 4.0 integration.

Envision a world where machines communicate, adjusting settings for real-time production optimization. This is not science fiction. It is the future of manufacturing led by SLTL Group—a laser technology pioneer with 25,000+ installations across 45+ countries. SLTL is rewriting manufacturing rules with innovative laser solutions and Industry 4.0 readiness.

Laser powerhouse

At the heart of SLTL’s revolution are their ultra-high-power laser-cutting machines. These marvels, boasting up to 60 kW, intricately handle materials like mild steel, stainless steel, aluminium, copper, and brass. Intelligent features, such as Ether CAT systems and high-power motors, facilitate dynamic laser piercing 5 times faster across various thicknesses. Imagine cutting even the toughest materials a fraction of the time, boosting production and reducing costs.

Beyond pipe cutting

SLTL is not just about cutting flat sheets. SLTL goes beyond flat sheet cutting, introducing laser automation to pipe and tube processing. The Tube Cutting Series, including T6150/T6200/T6300, and potential automation for Bevel Cutting, Tube Slitting, and Automatic Loading-Unloading system, reflects a re-imagination by laser experts. This series meets intricate industrial needs, with integrated hardware and software enabling SLTL’s Laser Tube Cutting machines to handle diverse tube shapes—square, round, rectangular, various angles, channels, and even some angle profiles.

Flexibility meets superiority

SLTL introduces the X5, a 5-axis laser cutting machine designed for intricate parts. Equipped with additional A and C axes, it provides unparalleled flexibility in processing sheet metal components of diverse sizes and configurations, particularly in industries such as automotive. Eliminating the need for additional systems through one-time programming streamlines tasks, ultimately enhancing efficiency.

Welding perfection

In welding, SLTL’s high-power laser machines stand out as superior. These welding innovations provide rapid speeds, exceptional efficiency, and minimal heat-affected zones, resulting in strong joints with aesthetically crafted seams. Imagine tailored solutions for various industries, spanning sheet metal, aerospace, automotive, medical equipment, and pipes, all achieved with the precision of laser technology.

From the streamlined construction of vehicle bodies to the intricate assembly of battery packs, SLTL Group’s laser welding solutions address every facet of electric vehicle manufacturing. Their high-powered machines ensure sturdy and seamless welds, while robotic automation accurately handles intricate geometries. Handheld lasers offer creative flexibility, and specialized technologies are employed for bi-metal joining and uniform circumferential welds.The future is now

SLTL embraces rapid technological advancements, spearheading the way into the era of Industry 4.0. Envision machines empowered by the Internet of Things (IoT), collecting real-time data and utilizing it to make informed decisions, thus enhancing production efficiency. This revolutionary technology turns laser solutions into smart entities, facilitating seamless communication and refining the manufacturing process.

Beyond Just a Tool

Imagine a 60 kW laser cutter seamlessly incorporated into the Industry 4.0 framework. It evolves into an intelligent device that adjusts to production requirements. It monitors material engineering and performance, optimizing energy consumption. This is not merely a machine but a glimpse into intelligent manufacturing excellence. Real-time data enables operators to fine-tune parameters for precision and productivity. Predictive maintenance ensures smooth equipment operation, minimizing downtime and costs. With IoT, even automation and inventory management for laser solutions become easily accessible at all times.

Shaping the future with the SLTL advantage

The relentless dedication to innovation by the SLTL Group has undeniably revolutionized the industrial sector. Whether it is ultra-high-power cutting, top-tier welding, advanced automation, or seamless integration with Industry 4.0, SLTL’s holistic solutions establish unprecedented benchmarks for precision, efficiency, and flexibility. As we progress into a future characterized by intelligent and interconnected machinery, the SLTL Group serves as a guiding light, leading the path towards a manufacturing ecosystem that is brighter, safer and more efficient.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.