New challenges for parts and component cleaning

By OEM Update Editorial September 18, 2023 5:43 pm IST

The advancements in technology and society are not limited to component cleaning alone. In addition to new products, materials, and production technologies that necessitate customised cleaning solutions, there is a shift in the requirements for industrial parts and surface cleaning due to trends like energy and resource efficiency and the rapid progression of digitalisation.

Component cleaning has become vital in production across various industries, ensuring that downstream processes meet necessary standards and uphold product quality. However, the nature of these tasks has undergone significant transformations in recent years due to industry-wide structural changes. Moreover, there is a growing demand for cleaning processes to be more sustainable, energy-efficient, and resource-efficient. Additionally, the integration of cleaning into digitally connected production environments and the utilisation of AI is becoming increasingly important.

New applications due to the mobility and energy transitions

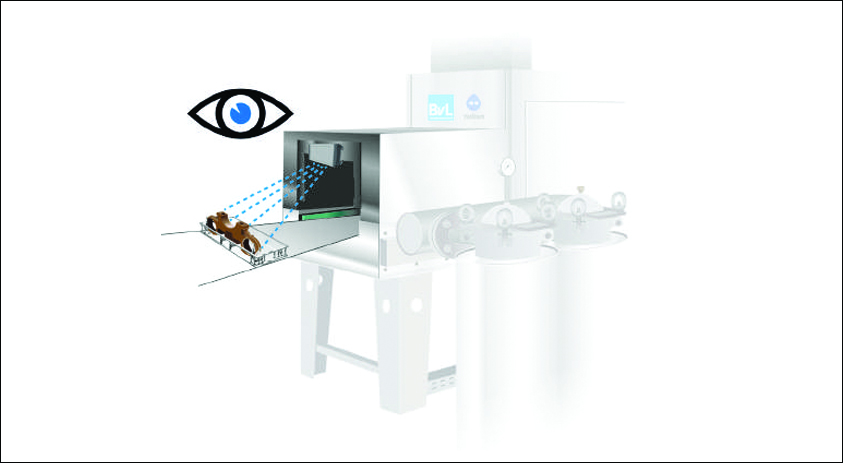

From electric vehicles and heat pumps to wind turbines and photovoltaic modules, products and solutions for mobility and energy transitions are leading to new applications in industrial cleaning technology.

In electric mobility, in addition to the classic components such as those for steering and braking systems, there are also mechanical drive components, including stators, rotors, housings and gear units. In some cases, relatively high particulate and/or filmic cleanliness requirements must be met for these tasks – which can usually be solved with wet chemical processes. Pre-assembled electromechanical components, on the other hand, require dry cleaning solutions. The requirement is that they can be easily integrated into production lines – if necessary, subsequently – and enable efficient cleaning in the production cycle. The cleanliness of production equipment, such as handling systems and grippers, also plays a role in avoiding re- and cross-contamination.

Cleaning in high-voltage technology like inverters is also receiving more attention. The focus here is no longer only on avoiding short circuits but also flashovers. Various tasks for wet-chemical and dry cleaning also arise in producing battery cells and systems, as well as fuel cells, in which the requirements for particulate cleanliness extend into the range of ten micrometres. Dry cleaning technologies like laser cleaning also benefit from the trend towards the cold body-in-white in the automotive industry. In this context, bonding is increasingly used in car body construction, and the joining surfaces are selectively cleaned.

Sensor and microsystems technology on the rise

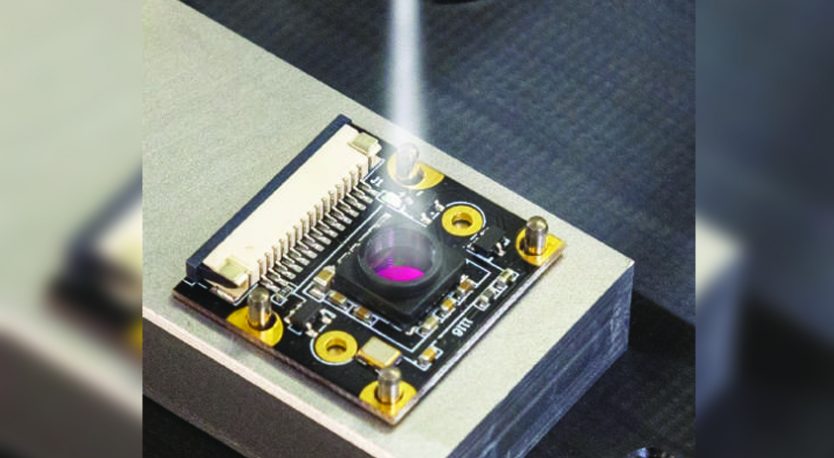

Whether it involves autonomous driving or the digitalisation of manufacturing processes, the presence of reliable sensors, microsystems, and monitoring technology is a fundamental requirement. Camera systems, for instance, play a crucial role in meeting the increasing demands for performance and reliability in these technologies, especially as they become smaller. The smaller the size, the more susceptible they are to impurities, making cleaning mechanical, electronic, optical, sensory, or actuator components incredibly vital. Achieving high levels of technical cleanliness is often necessary, leading to the need for precision or high-purity cleaning solutions. Sometimes, this may require specialised production environments, such as clean rooms, designed accordingly.

Automation and digitalisation of cleaning processes

Automation and digitalisation in cleaning applications have gained significant importance in recent times. The requirements go beyond the permanent recording, control and documentation of various system parameters, for example, monitoring and readjustment of pressures and temperature as well as condition monitoring of aqueous cleaning and rinsing baths – which have already been implemented.

In the meantime, there are demands for progress-dependent process control, meaningful monitoring of the process engineering sequences, and adequate storage and provision of relevant process data and information on technical cleanliness. Solutions for implementing these factors are already being offered in some cases and are being developed by practically all system manufacturers. One challenge is the availability and cost of metrological solutions. Likewise, manufacturers – often in cooperation with research institutes and/or partner companies – are dealing with the hot topic of artificial intelligence (AI).

Sustainability, energy and resource efficiency

Rising energy costs and stricter environmental targets have made energy and resource consumption crucial in determining investments in new cleaning systems. The impact of cleaning on the product’s carbon footprint is also becoming a significant consideration. Similarly, there is a growing interest in sustainable and energy-efficient cleaning solutions for existing systems. Manufacturers offer improved mechanical processes and more efficient drying technologies, such as condensation drying with heat pumps, to reduce consumption. Additionally, there is a focus on heat exchangers, heat pumps, and other systems that lower energy requirements, as well as software solutions for optimised energy management. Solvent cleaning may experience a resurgence due to its lower energy and resource consumption as long as it is equally suitable for the cleaning task compared to water-based processes.

From this perspective, alternative cleaning methods that achieve technical cleanliness without relying on energy-intensive heating of cleaning and rinsing baths and part drying are gaining importance.

Expertise shared by: Doris Schulz, parts2clean

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.