Indianised way of smart manufacturing

By OEM Update Editorial June 17, 2019 5:15 pm IST

Being an SME, we rose to the rising demand for continuous development of new products and efficient components for existing machines, says, Ankit Sahu (Director), Objectify Technologies Private Limited as he discusses how everyone should promote indigenised way of smart manufacturing.

Make in India the dawn of ‘New India’.

Make in India is indeed the dawn of ‘New India’. It has provided much boost to Indian manufacturing industry. With the demand of durable and robust products, the rise of Make in India has facilitated with ease of production, meanwhile maintaining quality. With many companies setting up base here in India it has enhanced the condition of Indian SMEs with continuous business and demand for quality products. There has been a rising need from almost all the industries. As many companies are setting up base in India they need to source products and services to keep the cost low.

MSME adopting latest technologies

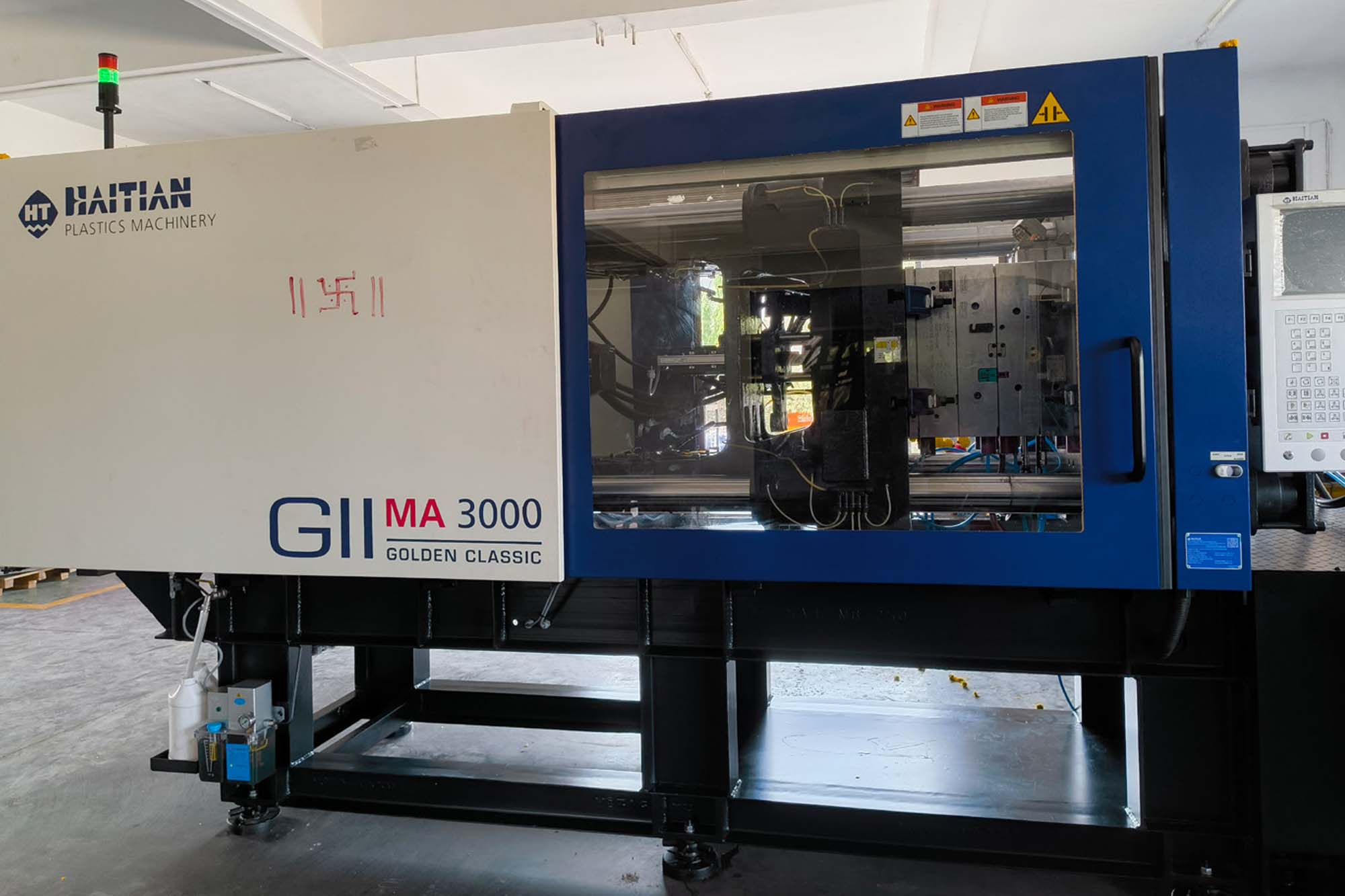

MSME is still lagging compared to the matured industries and companies. However, there has been considerable change in adoption of latest technologies. MSMEs have realised that to serve the demand from OEMs for quality and precision parts, they need to enhance their infrastructure and work on skill development. I feel Indian MSMEs are well aware of the changes and moving towards the right direction. You can take our example. With the rising demand for continuous development of new products and efficient components for existing machines, we have been acting as a catalyst to industries by 3D printing components at a rapid rate. To talk about the challenges, I would say SMEs in India do not enjoy the kinds of benefits that people in China have. For us, adequate finance is still a daunting task, infrastructure is poor, finding skilled manpower is another challenge.

Every country and every smart manufacturing solution provider are trying to push their own way of smart manufacturing. However, every country has a different challenges and infrastructure issues. In India, associations and government body should work closely to promote Indianised way of smart manufacturing.

Smart manufacturing core of Industry 4.0Upgradation is in the essence of industrial future proofing and adaptation. As industrialists evolve to a more digital working environment, industries with smart manufacturing process are in the core of Industry 4.0.

For a smooth transition, industrialists, factory owners and government bodies should consider automation adaptation with skilled labour, capital goods upgradation, training skilled manpower, creating smart ecosystem across the supply chain, defining improved safety norms, and government assistance for resource pooling

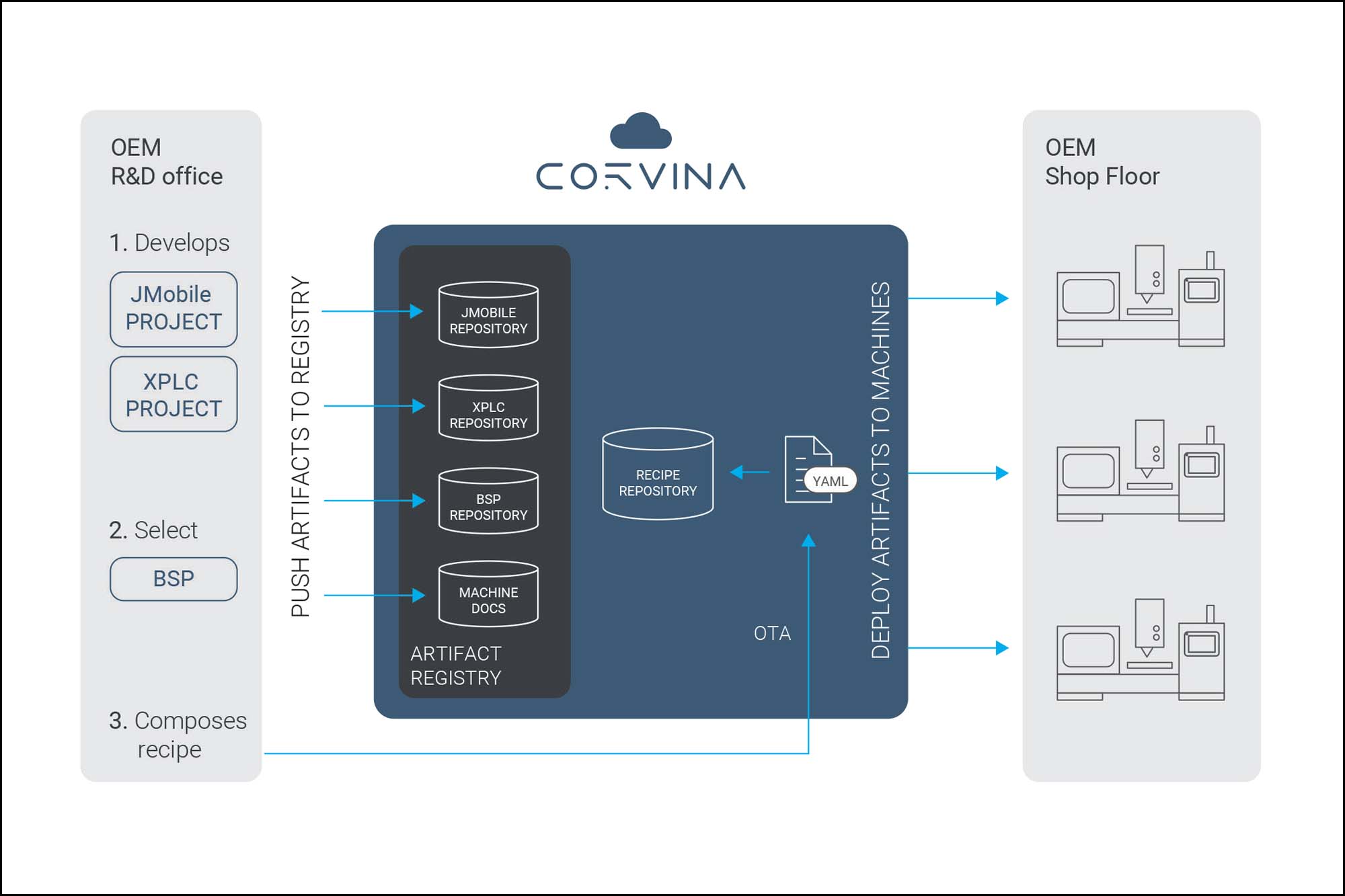

Cloud solutions and connected manufacturing for machine tools industry

Cloud manufacturing and smart factory are the future of manufacturing, and is in the essence of Industry 4.0. Connected machines provides you essential data that can be used for predictive and preventive maintenance. With the help of smart manufacturing, we will be able to monitor our shop floor and machines from any part of the world.

The disruption for adoption of smart manufacturing will be felt 360 O across all operations

Ankit Sahu, Director, Objectify Technologies Private Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.