Sustainability initiatives spark debate over environmental impact vs. technological advancement

By OEM Update Editorial April 19, 2024 6:42 pm IST

Embracing sustainable practices in India’s machine tool sector: A path to greener manufacturing

In the rapidly evolving landscape of India’s machine tool market, the imperative for sustainability has taken center stage. Prakash G, Chief Operating Officer at Ace Designers Limited, highlights the company’s pioneering efforts in adopting eco-friendly practices, aligning with global sustainability frameworks such as the Sustainable Development Goals (SDGs), Business Responsibility and Sustainability Reporting (BRSR), and Environmental, Social, and Governance (ESG) principles to foster a more sustainable manufacturing ecosystem.

The burgeoning focus on sustainability is particularly pertinent in the manufacturing sector, given the pressing challenges of climate change, resource scarcity, and evolving customer expectations. The shift towards green manufacturing echoes the principles of pre-Industrial Revolution eras, where minimal environmental impact was the norm.

The industrial processes, accounting for approximately 16.8% of emissions in the manufacturing industry, underscore the urgency to address carbon footprints. Efforts to mitigate greenhouse gas emissions, particularly carbon dioxide, are paramount for sustainable manufacturing practices.

Key trends in green manufacturing encompass various facets including product design, reverse logistics, recycling, advanced materials, and the integration of nanotechnology within Industry 4.0 frameworks. Additionally, decentralised manufacturing, eco-friendly packaging, and the adoption of artificial intelligence for energy optimization are shaping the future trajectory of sustainable production.

Business Responsibility and Sustainability Reporting (BRSR) has emerged as a mandatory framework in India, serving as a conduit for companies to disclose non-financial aspects of their operations. Aligned with SDGs, BRSR principles encapsulate the holistic approach towards sustainability, emphasizing environmental stewardship and societal well-being.

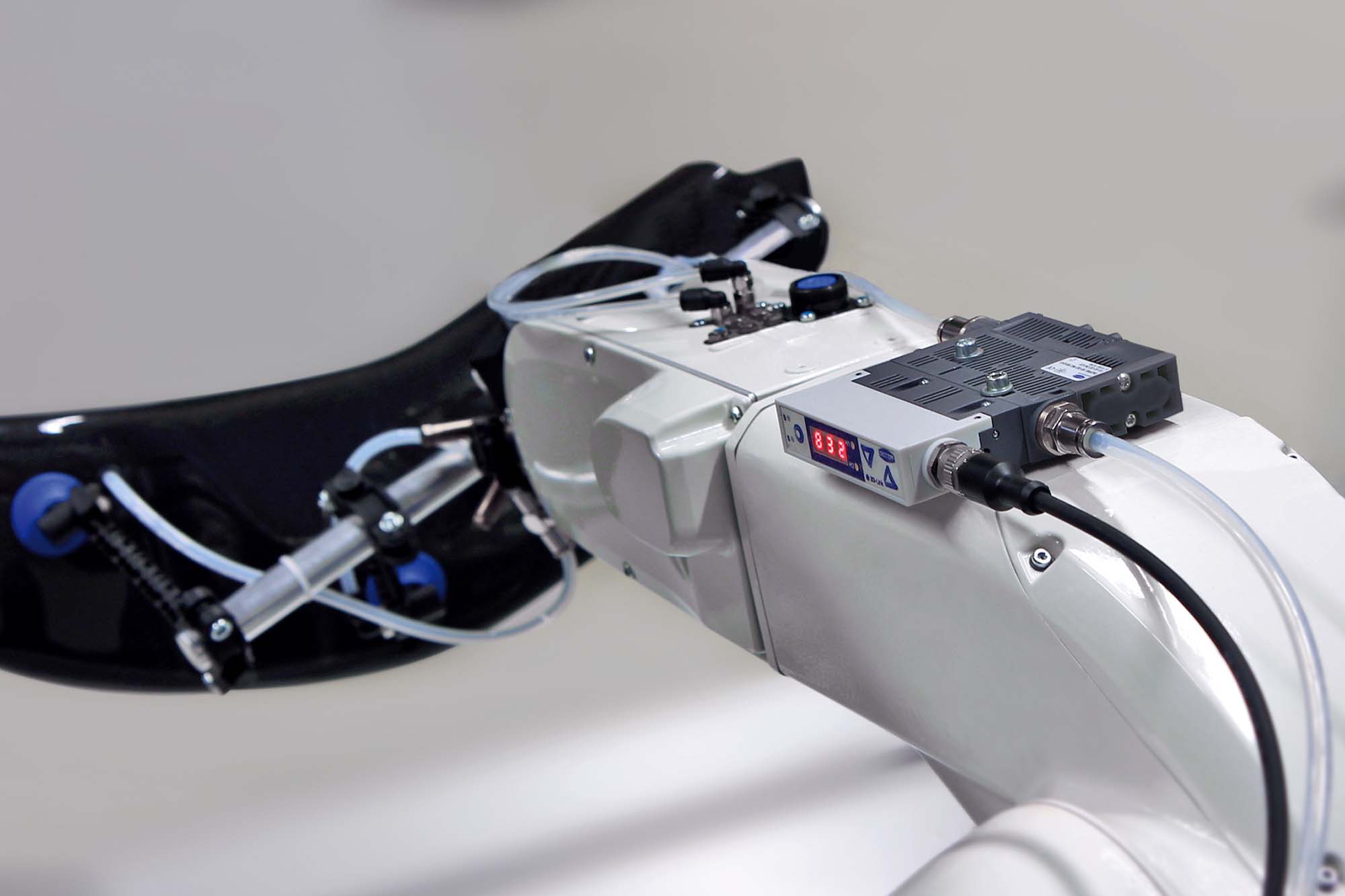

The machine tool sector- mother industry , as a critical component of the manufacturing value chain, faces unique challenges in reducing its carbon footprint. Energy-intensive machining operations necessitate a concerted effort towards sustainable practices, encompassing efficient resource utilization and emission reduction strategies across the supply chain.

Lifecycle assessments play a pivotal role in evaluating the environmental impact of machine tools, prompting a shift towards energy-efficient solutions and materials. Initiatives such as 3D printing and Near net shape manufacturing offer both opportunities and challenges, demanding innovative approaches to minimize energy consumption and material wastage.

Founded in 1979 by three visionary entrepreneurs from CMTI – Mr. Shirgurkar, Mr. Machado, and the late Mr. Sathe, ACE Designers has evolved into a premier manufacturer of CNC turning milling machines. Our unwavering dedication to environmental stewardship is underscored by our pursuit of Greenco certification, culminating in the recent attainment of the prestigious national best green gold certification. Further the adoption of green practices such as solar rooftop panels, and other initiatives to minimize waste, energy consumption and reduction of plastic usage are gaining higher prominence through the concept of 3R – reduce, reuse and recycle. On the Machine tool as a Product, sustainability concepts are being evolved through design for sustainability to minimize impact to environment in its entire life cycle. Efforts are being made to refurbish and reuse old machines towards its end of life cycle.

ACE Designers is committed to sourcing approximately 90 percent of our energy from green sources. Furthermore, we have meticulously developed a comprehensive roadmap for Environmental, Social, and Governance (ESG) sustainability, which extends far beyond our operational scope. This unwavering commitment is deeply ingrained in our vision and mission.

Collaborative efforts towards incorporating sustainability practices into machine tool design and manufacturing by the Indian Machine Tool Manufacturers Association (IMTMA) further underscore the industry’s collective commitment towards sustainability.

The integration of ESG practices is no longer a choice but a business imperative, with tangible impacts on financial performance and investor choice. Indian OEMs and machine tool builders must embrace ESG principles, fostering collaboration and innovation to remain competitive in the global market.

Government intervention in the form of grants, tax incentives, and carbon credits is crucial for fostering a conducive environment for green manufacturing initiatives. Such measures will not only incentivize sustainable practices but also stimulate collaborative partnerships among industry stakeholders.

In conclusion, the journey towards sustainable manufacturing in India’s machine tool sector necessitates a concerted effort from industry players, policymakers, and regulatory bodies. By embracing eco-friendly practices, adhering to global sustainability standards, and fostering collaborative innovation, the sector can pave the way for a greener and more resilient future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.