RHI Magnesita customises refractories for every industry

By Staff Report October 29, 2024 4:49 pm IST

RHI Magnesita leads the refractory industry with its customised solutions for improving durability and efficiency in high-temperature manufacturing setups. These solutions prioritise sustainability and incorporate Industry 4.0 principles.

How do your refractory products enhance durability and performance in high-temperature manufacturing units?

Our refractory materials and solutions are designed to endure temperatures of 1200 degrees Celsius, making them vital in steel, cement, and glass industries. Our high-quality magnesia and alumina-based bricks and mixtures are engineered to provide excellent thermal resistance and mechanical strength. Our products and solutions produce high-quality steel, cement, and other items by reducing wear and tear in high-temperature processes. This longevity leads to less downtime and lower maintenance costs, allowing projects to reach their full potential.

Furthermore, our cutting-edge manufacturing facilities and stringent quality control procedures ensure that every product meets the highest industry standards. Our refractories function well under pressure and increase the overall efficiency of high-temperature processes.

How does RHI Magnesita customise products for the steel and glass industry?

We understand that different businesses have distinct requirements based on their casting conditions. Our customising approach entails a thorough grasp of each industry’s operations, difficulties, and objectives. We specialise in long-term solutions that enhance the steel industry’s furnace durability and casting performance.

We customise our speciality products for the glass industry to handle thermal stress and maintain accurate temperature control. This tailored solution strategy is backed up by our world-class R&D department in Bhiwadi, where our experts work directly with clients to create customised products that fit their operating requirements. We ensure our products work optimally in various applications by focussing on innovation and client feedback.

How is RHI Magnesita incorporating eco-friendly practices in its refractory products?

We are devoted to sustainability and actively incorporate environmentally friendly techniques into our operations. Our recent Sustainability Report describes our recycling and resource conservation efforts. We use recycled materials in our refractory production processes, reducing waste and environmental footprint. RHI Magnesita has developed proprietary technologies to increase the utilisation of secondary raw materials without sacrificing refractory performance. This aids customers’ decarbonisation efforts by decreasing waste and CO2 emissions that would otherwise be emitted while processing fresh raw materials.

Our R&D activities are focused on developing creative solutions that align with global environmental goals. By creating cross-industry alliances and engaging stakeholders, we hope to inspire collective action towards a more sustainable future in the refractory sector.

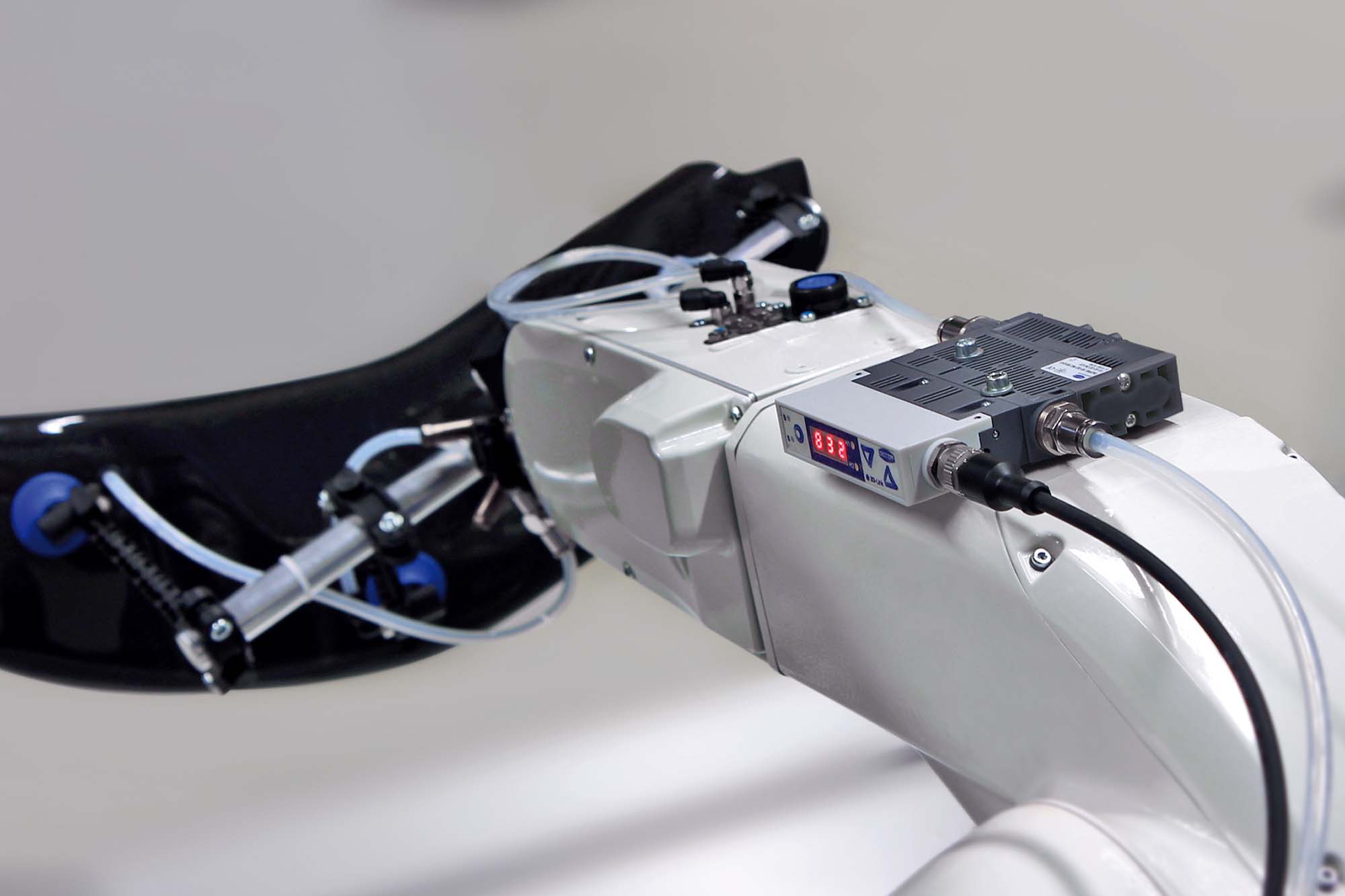

How is RHI Magnesita applying Industry 4.0 principles, and how does this impact product development and production efficiency?We are at the forefront of sector 4.0 integration, with revolutionary robotics technology applications in the steel sector. Our robot solutions improve crucial processes like ladle handling and slag management, increasing safety and productivity. For example, technology such as SX3 slide gates and EMLI LadleSlag sensors help India achieve its objective of reaching 300 million metric tonnes of steel production capacity by 2030.

Our Lining Evaluation Scan (LES) technology is changing how we evaluate rotary kiln linings in the cement industry. By giving correct thickness evaluations in four hours, LES reduces the inefficiencies of older approaches, which can be time-consuming and subjective. Our data-driven approach enables our clients to make informed repair decisions quickly.

What are the main challenges facing the refractory industry, and how is RHI Magnesita addressing them?

The refractory business has faced several issues, including supply chain disruptions, which have increased raw material prices. Furthermore, end-user sectors have experienced a slowdown resulting in lower import costs, but rises in raw material and freight prices have brought new obstacles. However, we are moving forward with our strategic goals to enhance our market share (iron-making, flow control) and achieve operational excellence and synergy. We have managed this volatility by maintaining good margins and delivering long-term, profitable growth.

We firmly believe the growth would necessitate the refractory industry catalysing to assist Viksit Bharat. RHIM India is ideally positioned to seize this opportunity as the market leader.

What role do global industry associations play in shaping the future of refractories and high-temperature processes?

Global industrial associations, such as the World Refractories Association, play an important role in determining the future of the refractory business. They encourage important stakeholders to collaborate, share expertise, and develop best practices throughout the sector. These organisations are critical in solving common concerns such as sustainability and innovation by offering a forum for collaborative action and advocacy. The World Refractories Association also assists in standardising techniques that improve safety and efficiency in high-temperature processes. As the sector evolves, associations serve as a resource for research, training, and development, ensuring that members keep up with technical advances.

By cultivating a community of shared expertise and vision, we can collaboratively drive advancements and address industry concerns, ultimately contributing to a more sustainable and efficient future for refractory materials.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.