Manufacturing gets enormous benefits from digitalisation

By OEM Update Editorial June 9, 2023 2:07 pm IST

Uday Dixit, General Manager, Polyworks India, talks about a strategy to focus on helping the customers in the digitalisation of their entire inspection process and assist them in preparing a roadmap with the investment in a phased-out manner.

How do your software solutions manage 3D measurement data digitally?

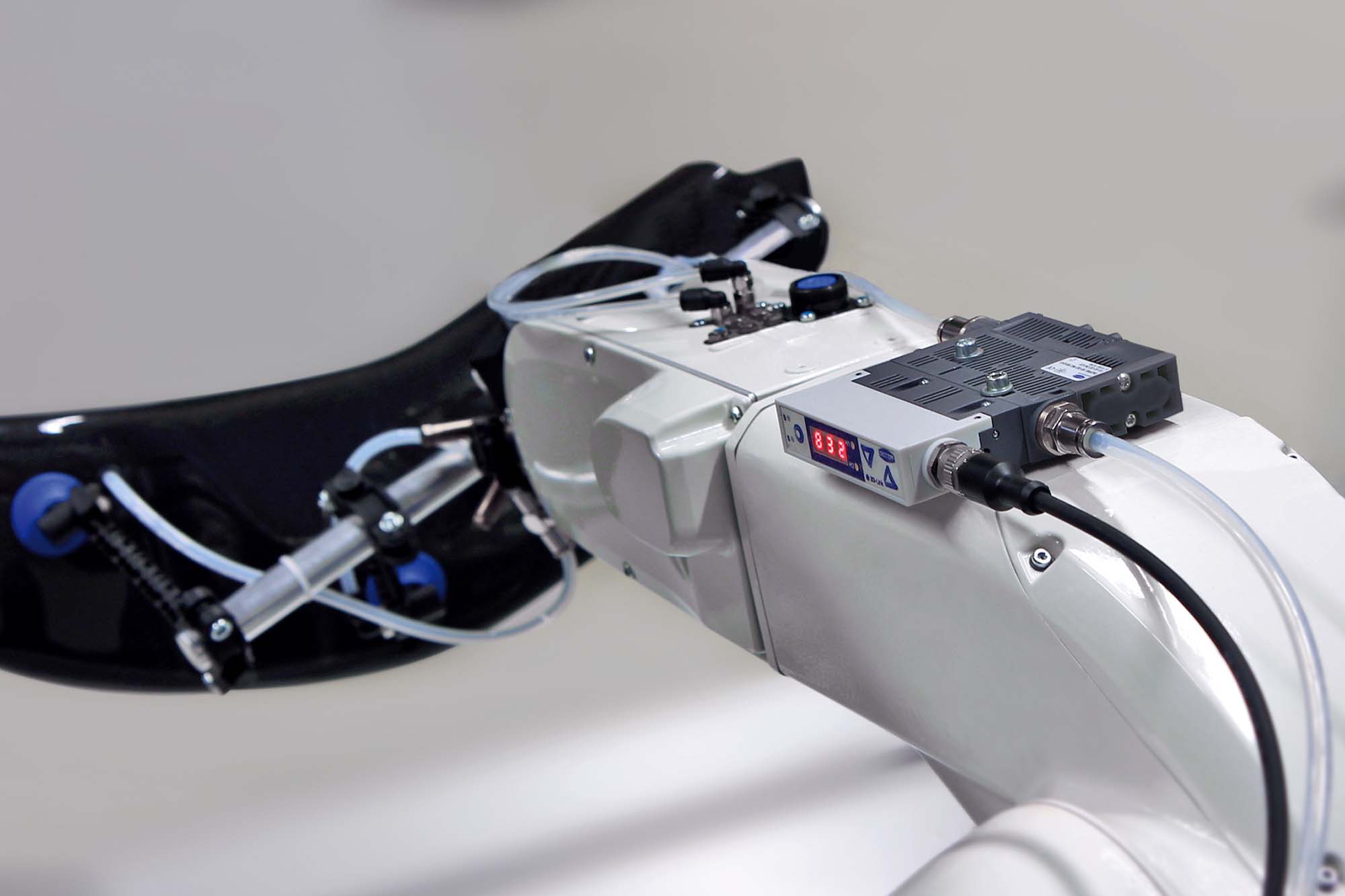

PolyWorks India is a subsidiary of InnovMetric, a multinational software development firm based in Canada. With a more than 500 professional workforce, the company focuses on integrating 3D measurement data into manufacturing operations. Their software solutions aid original equipment manufacturers (OEMs) in charting a path towards digitally transforming their 3D measurement processes. By enabling digital management of such data, the software promotes collaboration between OEMs and their subcontractors. With our software solutions, various departments, such as design, manufacturing, and 3D measurement teams, can manage their parts’ dimensional controls within their own native CAD platform to automate the propagation of design changes.

How do you evaluate the growth of measurement tools for applications in manufacturing industries?

The Indian Manufacturing Industry is evolving. It is transforming from traditional products such as automotive parts to new aerospace, electronics and medical sectors. All these industries demand high quality for the export parts and the domestic market. This will spur an exponential growth of measurement tools and digitalisation of the measurement process.

Can you explain the benefits of implementing sustainable manufacturing practices in India?

What advancements have taken place in the calibration of instruments and measuring devices?While calibration of any measuring instrument is essential in ensuring its performance, it’s not enough, as this is just a one-time activity. Consequently, an increasing number of companies, particularly those involved in producing high-precision components, are placing greater emphasis on Gauge Repeatability and Reproducibility (GR&R), to say in short GR&R. It indicates the actual capability of the measuring instrument. This is a more elaborate and flexible procedure, as the user can define all the parameters depending on their application. We have a simple software solution to monitor these parameters without manually exporting all the measured results into third-party software like Microsoft Excel.

According to you, what is the crucial challenge sustainable manufacturing practices face?

According to us, the customers are looking for the “right partners” who could not only guide them in “charting the path” to follow sustainable manufacturing practices but also support them until all the milestones are achieved. They are looking for initial handholding with strong technical know-how as well as a solid support structure.

What is your company’s future focus to meet market demands?

Our primary focus is to support customers in digitising their complete inspection process. We aim to listen to their needs, understand their priorities, and provide assistance in creating a phased roadmap for investment, ensuring a scalable project. We will deliver measurable benefits throughout each phase to accompany the digitalisation process.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.