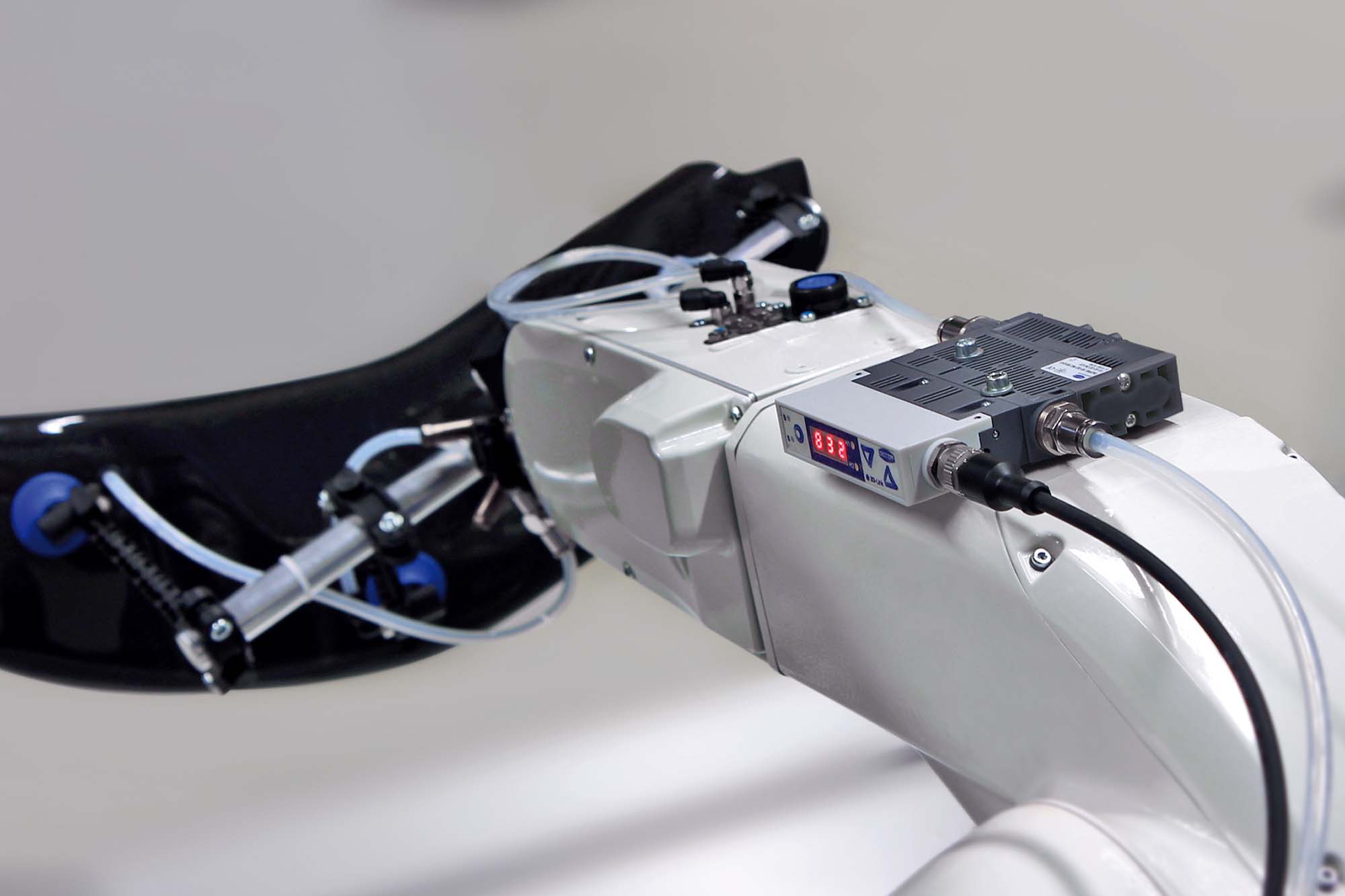

Complete System as if made from a single piece

By OEM Update Editorial May 11, 2023 6:55 pm IST

The 1,000-ton servo press for automotive supplier Wöhrle features numerous innovative extras.

A coil width of up to 1,300 mm including zigzag feed, residual strip processing, straightener with exchangeable straightening roll cassettes, and a die changing cart for the press to minimize setup times: The Schuler servo press installed by Wöhrle company at its production site in Krautheim near Heilbronn has it all. This versatile MSD 1000 press with a bed size of 4,000 by 1,800 mm thus provides the flexibility for the automotive supplier to be successful on the market.

“All companies of the automotive industry are currently undergoing a transformation,” says Managing Director Michael Fahrenbach. “Everyone is looking ahead, but no one knows for sure what products will come.” Hence, the more flexible the system, the lower the risk: “The maximum band width of 1,300 mm means we can cover an extremely wide range.” Consequently, there are no typical components for Wöhrle either: the product portfolio ranges from components for transmissions, battery systems, axles, sound and shock absorbers to air conditioning technology and power electronics. The width of the parts starts at 300 millimeters; the longest component developed to date measures 1,900 millimeters.

Parts made of steel, aluminum, stainless steel, and copper

The straightening system, with 17 instead of the standard nine straightening rolls, allows even demanding materials to be prepared in such a way that the final products meet the highest standards concerning geometry and quality. Regardless of the material being steel, aluminum, stainless steel, or copper – the only requirement is that the sheet metal fed in must have a thickness of between 0.5 and 6 mm. The zigzag feed from Schuler ensures high material utilization.

Thanks to a special transfer, even the last two or three meters of a coil, which are normally lost on conventional lines, can be utilized. “Thus, we minimize the scrap content,” explains plant manager Ulrich Reustlen. There was no ready-made solution for such residual strip processing on the market, so Schuler developed it without hesitation together with Wöhrle. “Resources are scarce all over the world,” adds Managing Director Fahrenbach. “By avoiding waste, we are doing a lot for sustainability.”

Sustainability is a top priority

But back to the latest new acquisition: Among other things, with the help of the die change carts, the complete plant can be changed over in just half an hour, and the tryout function provides support when setting up new dies. In order to identify possible collisions in advance and optimize part throughput, Wöhrle has also invested in Schuler’s “DigiSim” simulation software and the associated training for operators as well as die designers. Effective sound insulation guarantees pleasant working conditions, even directly at the press.

“Schuler can do that”

By the way, the coil line not only pushes the sheet forward, but can also pull it back a little if necessary. This opens up the possibility of using the press force in the forming process in a more targeted manner and, for example, producing parts that could otherwise only run on a 1,250-ton machine. “It was already clear to us in advance: Schuler can do that,” says plant manager Reustlen. Together with Schuler, Wöhrle developed and integrated the individual features one after the other: “Team spirit was a key to success.”

Both sides always supported each other with “passion and bite,” as Managing Director Fahrenbach puts it. The result, according to Reustlen: ” Everything we asked for was met.” All components are perfectly matched, he says, and the control cabinets are mounted above the conveyor system to save space: “It’s a system as if made from a single piece.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.