Efficient data centre cooling systems for water and energy savings

By OEM Update Editorial July 6, 2021 9:10 pm IST

There are many combinations of evaporative and mechanical cooling solutions that can be evaluated to meet data centre cooling requirements.

As the amount of digital information stored and streamed grows, so do the number of data centers required to support this growth. The massive computer power within these data centre generates heat, making efficient cooling a key building system requirement. Evaporative cooling towers are an integral part of many data centre cooling systems. Recently some have questioned the use of cooling towers, citing water scarcity to bolster their arguments, but a thorough examination of water use – for local onsite cooling towers compared to water use to generate power at regional fossil fuel power plants – reveals surprising results.

Data centre cooling options

There are multiple ways to cool data centers, depending on the size, computer capacity that must be cooled, regional energy costs and the data load and density. Popular options include:

- Water-cooled chiller plant – includes chiller system, pumps, cooling tower and plate/frame heat exchanger in series with the chiller

- Air-cooled chiller plant – includes chiller system and pumps

- Direct evaporative cooling – without mechanical refrigeration, also referred to as “swamp cooling”

- Adiabatic cooling – air-cooled system assisted by water-cooled system during peak conditions

To attract customers, data centre operators weigh the options and look for systems that reduce operating costs and environmental impact. They pay close attention to power use effectiveness (PUE), defined as the ratio of the total amount of energy used by a data centre to the energy delivered to the computing equipment. A PUE of 1 means the heat rejection power equals the power used for the computing equipment.

Data centre operators are also concerned about water use effectiveness (WUE). Cooling towers evaporate water, but the impact depends on location. According to Tim Chiddix, PE, VP of Mechanical Engineering at Swanson Rink, a leader in the design of data centre facility infrastructure, data centers can range from a few hundred sq. ft., to several hundred thousand sq. ft., and no cooling technology works well for all regions, client criteria and applications. “Each and every facility must be analysed to determine the approach that best meets the needs of the customer and takes advantage of energy and water savings opportunities of the particular region.”

Swanson Rink specifies equipment as part of its data centre practice and frequently combines cooling towers with mechanical chillers for efficient cooling.

Evaluate water use issues holistically

The drive to reduce water use has caused many companies to reexamine the impact of water usage for cooling data centers. Some have questioned whether onsite cooling towers use too much water. In evaluating the best cooling strategy for a data centre, it is critical to view water usage holistically, including water use, where the power is made. When viewed in this light, mechanical evaporative cooling systems are often far more efficient than alternative dry systems.

The amount of water used by the steam cycle of a fossil-fuel based power plant to generate electricity may be greater than the amount of water used by the data centre cooling tower. An example is an air-cooled system that uses 1 megawatt (MW) of power per year compared with a water cooled system that uses 0.5 MW per year and 3,000 gallons of water per minute. The number of gallons the power plant uses, to make the additional 0.5 MW to power the air-cooled system, is actually greater than the amount of water that would be used locally by the water cooled system’s cooling tower. Cutting down the energy used from power plants may actually save water.

Swanson Rink’s Tim Chiddix and Brook Zion evaluated the water use issue in a white paper, ‘Data Center Water Usage for Denver, Phoenix and Los Angeles: A Look at the big picture’. Chiddix and Zion examined whether reduction in water use at an individual data centre facility results in an aggregate reduction in water use for the regional water supply system.

The authors note that water is a more efficient medium than air for removing heat because evaporation enhances the cooling process. “Using water-cooled condensing systems versus aircooled condensing systems can significantly reduce your cooling energy costs; however the effectiveness of evaporative cooling is very location-dependent, since the drier climate results in greater efficiency.”

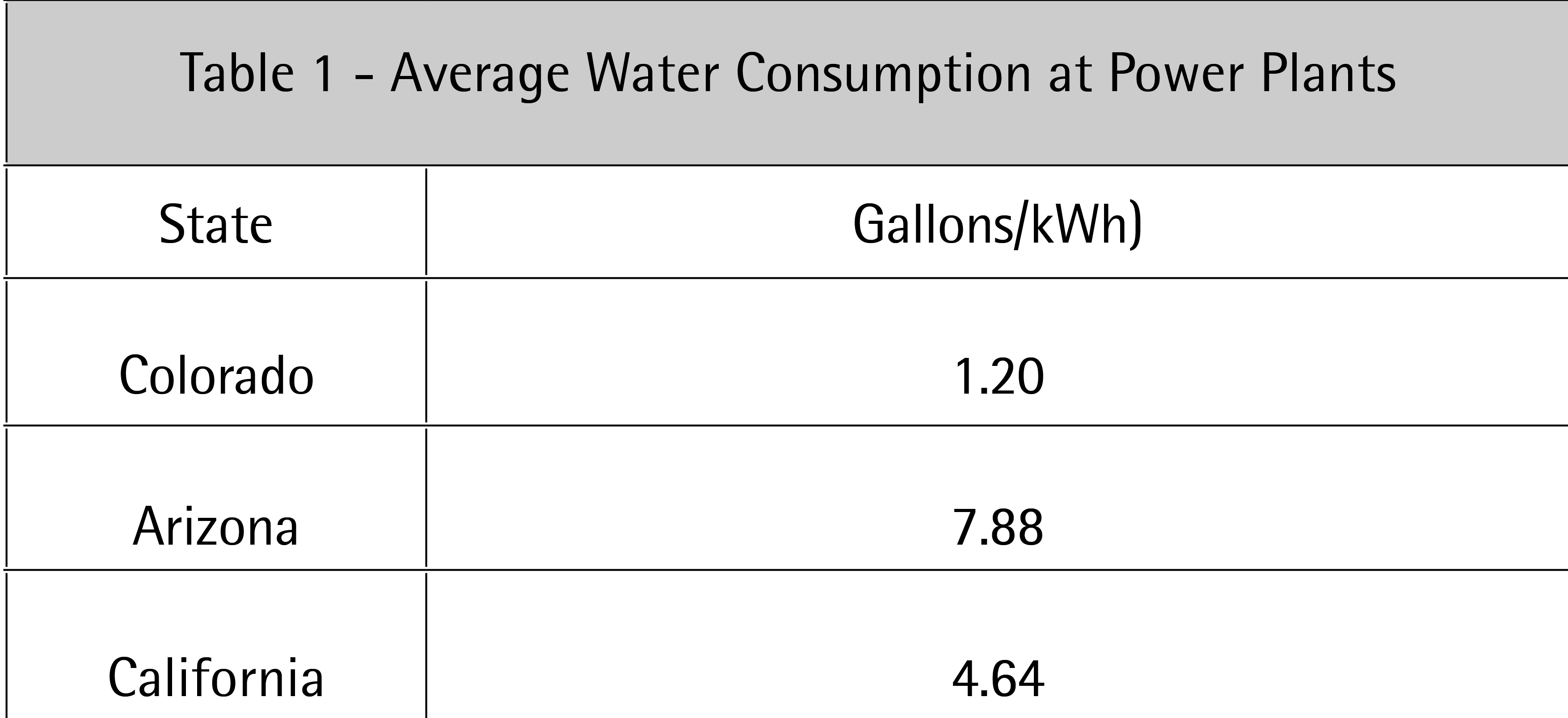

They studied whether this energy reduction comes with an increase in onsite water usage due to evaporation. They also considered whether this evaporation is wasting water and whether data centre owners should consider air-cooled equipment instead. The evaluation compared sample data centers located in Denver, Phoenix and Los Angeles, US. It examined the regional power grid to determine how much water the power companies consume to produce a kilowatthour (kWh) of power. Water consumption rate data from the National

Renewable Energy Laboratory (NREL) technical report TP-550-33906 is shown in Table 1.

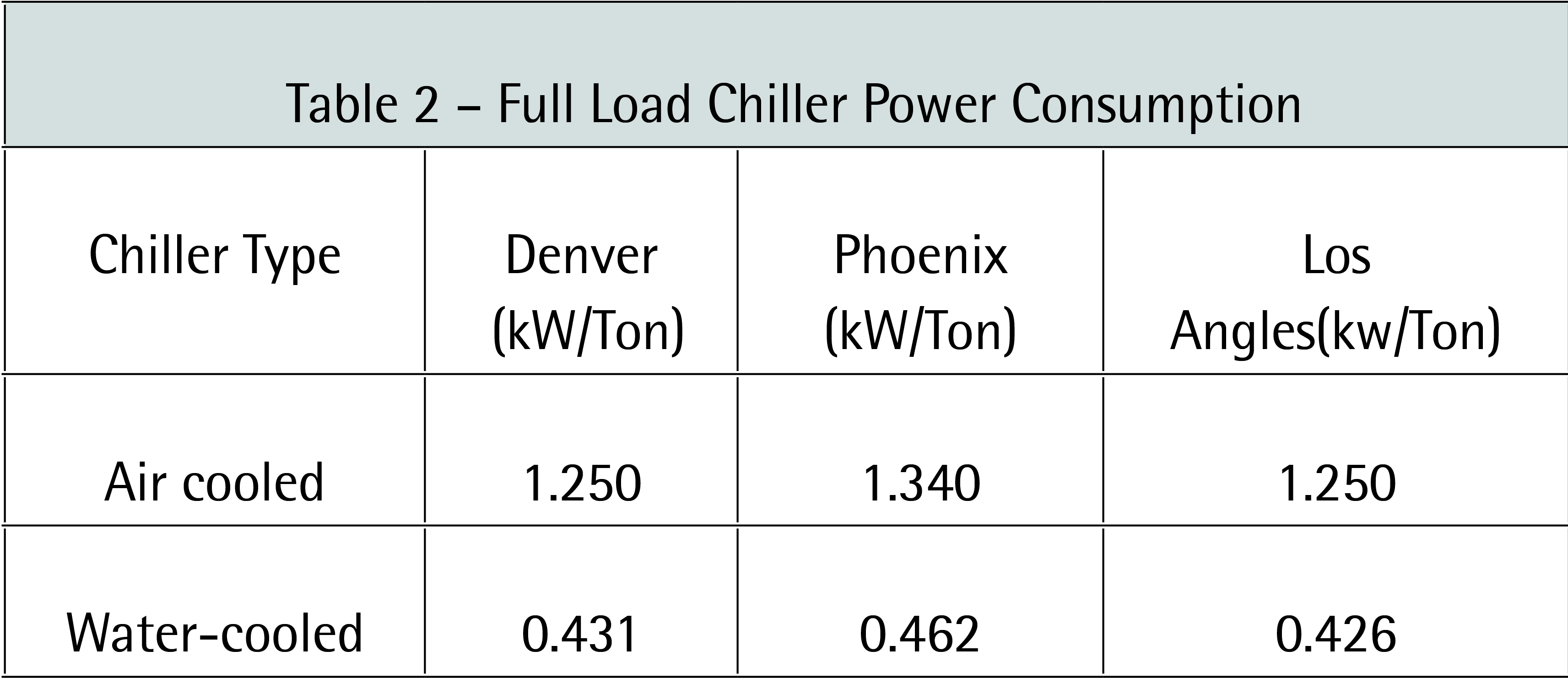

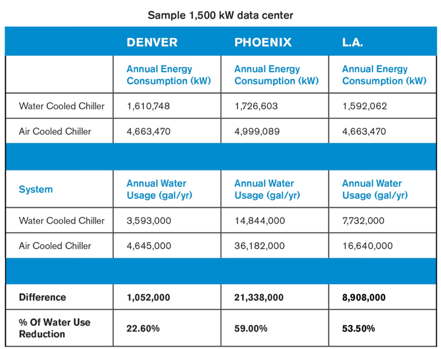

The study looked at cooling for a sample data centre with a steady 1,500 kW cooling load. The authors compared a standard efficiency water-cooled chiller system and a standard efficiency air-cooled chiller system, as well as an evaporative system with no mechanical cooling. The water-cooled plant includes a chiller system, pumps, cooling tower and plate/frame heat exchanger in series with the chiller.

The air-cooled chiller includes the chiller system and pumpsTable 2 shows the full load power consumption of the air-cooled chiller was significantly higher than that of the water-cooled chiller.

Water use, through evaporation, was based on dry-bulb and wet-bulb temperature data from a Typical Meteorological Year (TMY3) obtained from the National Solar Radiation Data Base (NSRDB). The authors found that the water-cooled chiller system in Denver consumed 1,610,748 kWh of energy and the air-cooled chiller system consumed 4,663,740 kWh annually.

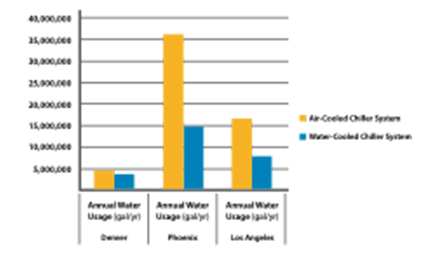

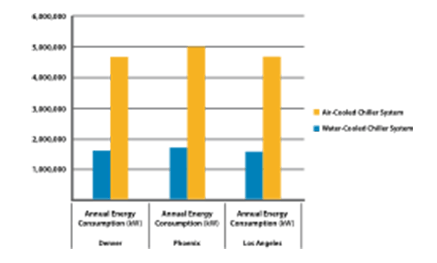

Figure 1 shows the energy and water usage for the mechanical chiller systems analysed in each city. Water use shows significant differences because the amount of water consumed at the power generation facilities is far greater than water consumed on site.

The air-cooled chiller system consumes more power and evaporates no water on site. All of its water use is at the rate of power plant water consumption. By contrast, the water-cooled chiller has lower power consumption and a combination of onsite and power plant water consumption.

According to Chiddix, municipalities requiring data centers to use less energy and water onsite may not have considered the full implications of these requirements. In his opinion, if the power generating plant is considered in the equation, the cooling technologies selected for the data centre may actually result in more overall energy and water use. Additional energy-saving factors to consider

Water-cooled technologies are more efficient, particularly when “free cooling” is employed during periods of cooler weather. Free cooling, also referred to as “water-side economiser” cooling, is an economic method of using low external air temperatures to assist in chilling water. When operating in free cooling mode, the water from the cooling tower is cold

Figure 1

Comparison of water and energy use in air-cooled and water-cooled chiller systems

Source: Data Center Water Usage for Denver, Phoenix and Los Angeles: A Look at the big picture, by Tim Chiddix, PE, ATD and Brook Zion, PE, ATD

Table 3 – Data for cooling system comparison enough that mechanical refrigeration by the chiller is not required. This reduces the energy requirement significantly, typically by 75 percent or more. To take advantage of the energy savings possible with free cooling, there must be sufficient hours of cold weather to justify the additional equipment investment for the plate/frame heat exchanger and other components.

An evaluation of the benefits of cooling towers in data centre cooling must also consider “variable flow,” another method to reduce energy consumption. Cooling towers are sized for summer design condition; variable flow enables users to reduce the water flow from the cooling tower to the chiller during cooler seasons. Fans are operated at a lower speed, which reduces energy usage. Taking advantage of free cooling and variable flow modes can dramatically reduce cooling tower energy use.

cooling must also consider “variable flow,” another method to reduce energy consumption. Cooling towers are sized for summer design condition; variable flow enables users to reduce the water flow from the cooling tower to the chiller during cooler seasons. Fans are operated at a lower speed, which reduces energy usage. Taking advantage of free cooling and variable flow modes can dramatically reduce cooling tower energy use.

Cooling tower modularity provides another advantage. Data centre owners may prefer to build out their facilities over time as server demand grows. To control initial capital expenditures and operating costs, data centre operators may add cooling capacity later as needed by using systems that incorporate factory-assembled modular cooling towers as the facility grows. It is important for data centre construction to be completed on schedule so that servers can be operational quickly to generate revenue. Modular pre-assembled and field-erected cooling towers can meet time-sensitive delivery requirements and construction schedules.

Weighing the water options

As the discussion of water is added to the list of design considerations, it is important to understand and evaluate the relationship between utility power and local water consumption in order to make well-reasoned decisions for achieving energy and water conservation goals.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.