Digitalisation in industrial gears

By OEM Update Editorial February 7, 2024 2:35 pm IST

In industrial processes, digitalisation initiatives benefit gearboxes, motors, and allied components. Firms embrace lean, green, and digital strategies, inducing innovation for high speed, reliability and cost-effectiveness. This includes utilising low-power motors to generate low-speed forces and optimising space.

The utilisation of geared motors in industrial settings is propelled by the ongoing modernisation of industrial infrastructure and the increasing energy demands in developing nations. In plant automation, these motors find common use in applications such as conveyor belts and overhead cranes. Geared motors are also integral in elevators, medical tables, jacks, and robots, as they generate strong driving forces at low speeds using cost-effective and low-power motors.

Gear shift in molecular motor

Artificial molecular motors harness external light energy to generate kinetic energy and are analogous to car engines. However, just as a car needs a gearbox to transfer power from the engine to the wheels, molecular motors require a mechanism to transfer kinetic energy to different molecule parts. Researchers, led by Professor Bo Durbeej at Linköping University, have developed a design principle for constructing molecular gears that can efficiently transfer rotary motion within a molecular system. Unlike previous attempts, this design allows for precise control over the direction of rotation. Previous designs have been unable to control the rotary motion, says Bo Durbee. Similar to the difference between conventional and electric cars’ drivetrains, the study highlights the need for molecular gears to utilise the generated motion in various applications efficiently.

Advanced technologies

Gearboxes and motors have a managing role in overseeing various industrial and repair operations in today’s industrial space. These devices are designed to regulate the speed of an electric motor, ensuring it operates at a specific velocity. Comprising gears arranged in a kinematic chain, these devices impact rotating components. The expanding manufacturing sector is generating a growing demand for these components. Hyundai has introduced a universal wheel drive system that relocates the reduction gear to the rim, eliminating the need for a CV joint. However, electric drive units still tend to be quite large. Hyundai asserts that it has developed a novel technology capable of reducing the size of its motors, creating more space for passengers and cargo.

According to Shailesh Sharma, the Director of Operations at SKF India and Southeast Asia, SKF India adopts a manufacturing strategy centred on Lean, Green, Digital (LGD) factories. The current digitalisation initiatives align with a growth strategy emphasising intelligence and sustainability to propel world-class manufacturing. The focus on digitalisation has enabled SKF India to innovate swiftly and gain insights, ensuring competitiveness in a landscape where speed, reliability, and cost-effectiveness are crucial.According to Fortune Business Insight, the global gear motor market is projected to grow from $7.03 billion in 2022 to $8.91 billion by 2029 at a CAGR of 3.4 percent in the forecast period, 2022-2029. Among the types, including helical gear, planetary gear, bevel gear, worm gear, and spur (in-line) gear, the bevel gear segment accounted for 26.72 per cent of the gear motor market share in 2021. The demand for helical gears is increasing due to their compact size. It is also used in several heavy industrial environments and high-performance applications. The planetary gear segment’s major share is characterised by its precision applications. This type of motor increases equipment life and optimises performance.

In material handling, the gear motors are used in conveyor belts for bulk and piece goods. Here, it supports and facilitates the transport, storage, and picking of goods and enormously speeds up processes in the process chain, particularly in the food & beverage, manufacturing industry, packaging and labelling. Demand for geared motors is growing rapidly as they help drive power generation equipment, including cooling towers, hydro turbines, and air condensers.

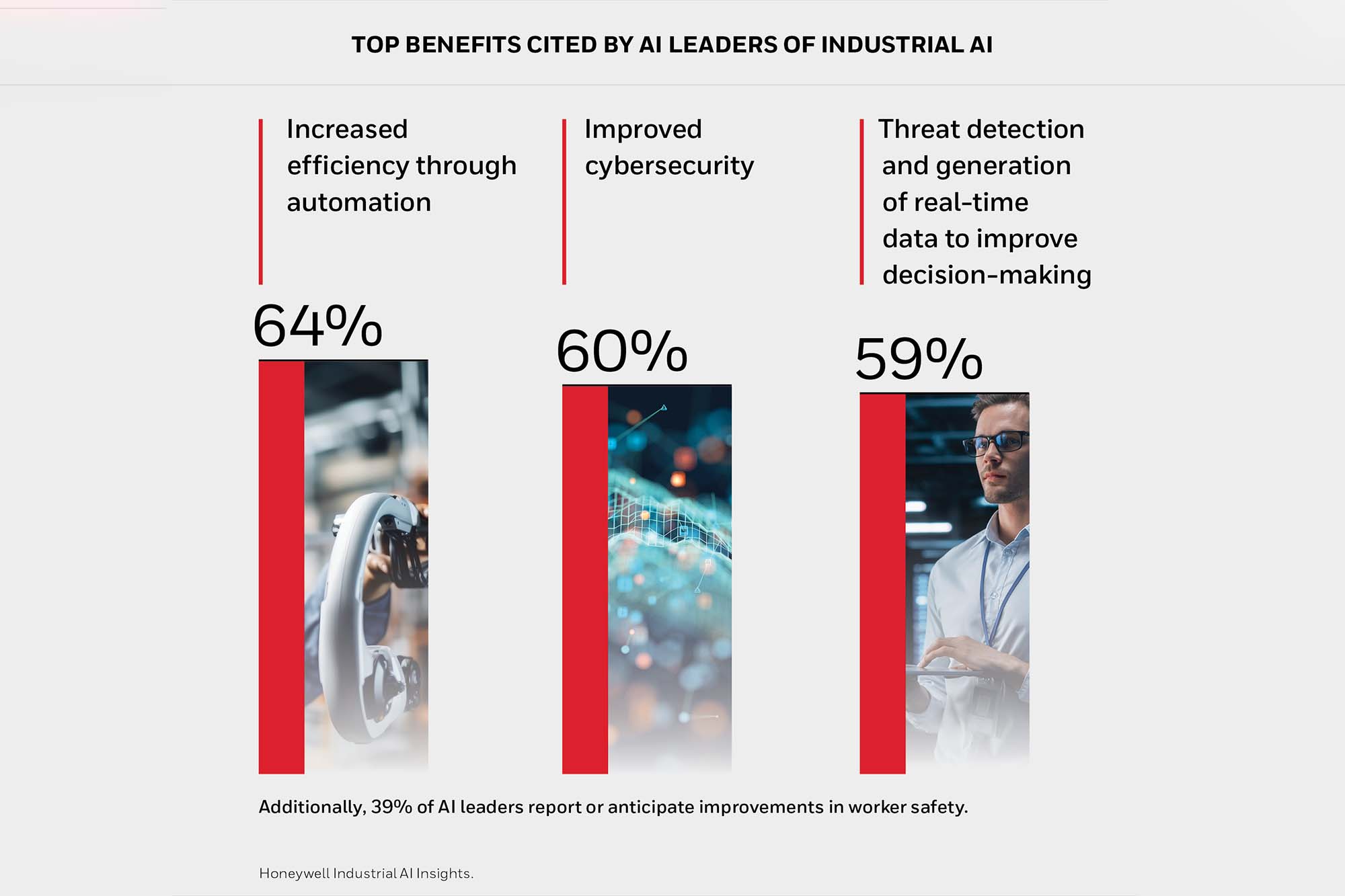

Advanced technology usage, like the Industrial Internet of Things (IIoT), artificial intelligence, machine learning, robotics, and 3D printing in manufacturing gears and motors, enables domestic manufacturers to enhance the efficiency of production processes and minimise downtime. These technologies elevate the quality and reliability of products by predicting maintenance and optimising resource utilisation. The ability to analyse volumes of data allows manufacturers to respond to shifts in market demand promptly and fine-tune their production lines accordingly.

Gears and motors are crucial in EVs, ensuring optimal performance and efficiency. In EVs, gears help manage torque and speed, while electric motors convert electrical energy to mechanical energy, powering the vehicle. Their synergy is contributing to the overall functionality and success of electric transportation. Electric cars, with their single-speed transmission and maximum torque at zero RPM, illustrate a shift in drivetrain dynamics compared to traditional ICE vehicles. The designers of electric cars typically select a gear ratio that strikes a balance between acceleration and top speed.

Going by the transition and shift in the present scenario, the fact lies in the efficient management of motor and drive systems. The utilisation of geared motors in industrial settings is driven by modernisation and increasing energy demands. Molecular gears in artificial motors offer precise control, meeting the need for efficiency in industrial gears. Advanced technologies like IIoT and AI enhance gear and motor manufacturing. In the EV sector, gears and motors are useful and centric for optimal performance, bringing a transitional shift in drivetrain dynamics for cost savings and reliability in the coming times.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.