Carbon footprint reduction in India’s sustainability journey

By OEM Update Editorial March 18, 2020 2:13 pm IST

Industries incur huge cost on traction, UPS, and solar batteries while it requires only 25 percent cost to revive it to its original level.

All lead acid batteries get degraded because of aging and sulphation. Timely refurbishment after two-third years of life/usage of new battery gives altogether new life that is equivalent to a new battery.

- Sectors using batteries: manufacturing (automobile, textiles, machining, pharma), banking, telecom, hospitals, call centres, software companies, textiles, railway component manufacturers, MHE manufacturers, etc.

- Refurbishment of lead acid batteries can be done for (flooded, AGM, GEL, etc) UPS, inverter, traction, telecom, substation, e-rickshaw, etc.

- Analysis of traction battery cells is imperative for all types of Material Handling Equipment (MHE).

R&D for 100 percent organic additives

- Organic additive polymer fibres containing inorganic salts and various seaweeds extract.

- Environmentally friendly.

- Ten times the conductivity of the existing additive conductivity.

- Mechanical strength three times the existing additive.

- High interaction between sulphuric acid (electrolyte) and additive.

- High additive absorption on the cathode area (negative plates).

- High adsorption in AGM batteries.

Discharge efficiency of batteries being compared before and after process to get warranty on old batteries again. In India, this process was first initiated in 2017 and today, several corporates are enjoying a wide variety of commercial advantages along with their CSR carbon footprint reduction/carbon credits. Many players have started this refurbishment process in haphazard way with half knowledge and no additive usage.

Refurbishment has two parts: One is desulphation; second is adding catalyst/additive. Customers must ask companies about their refurbishment machine process, principal employer support, legal agreement with principal employer of technology transferred, machine software reports sample, authorised laboratory reports, patent number and its related papers which needs to be verified.

Capacity of refurbished machines: In case of failure during process, one should verify vendor’s support for replacement of battery cells. Ask for before and after results.

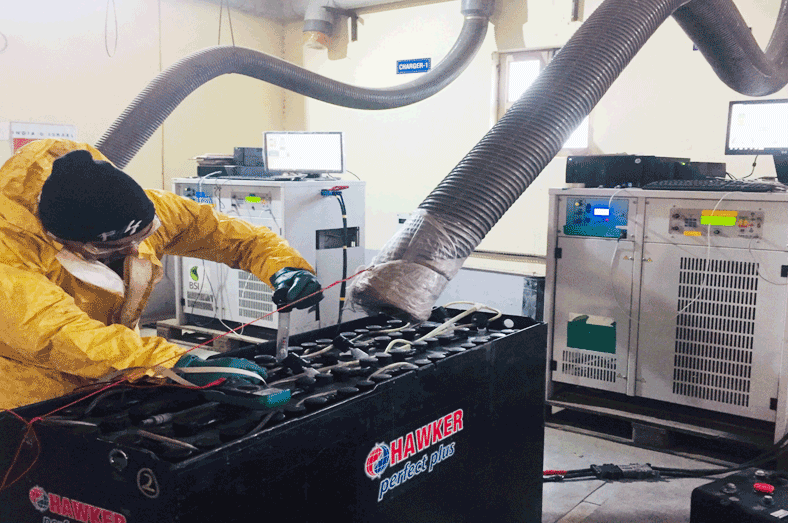

Refurbishment ProcessGiving IDs to each battery, labelling, cleaning, checking external condition and voltage of the batteries, open valves, grouping according to same capacity, charging using different programmes (up to 30 hours) and discharge as per battery manufacturer’s specification (charging/discharging cycle), stopping after the capacity reaches above 90 percent (try at least 5 cycles). Then, if the result is satisfactory, add additive (use 100 percent organic additive having good lab test records available) and do final charging, cleaning and packaging of ready-to-deliver batteries.

Solution: Yes to refurbishment; no to recycle

All types of old batteries revival: No more battery replacement

Myth: Replacement and recycling of batteries is the only solution.

Fact: Battery health revival is easily possible.

Myth: Refurbished batteries have high risk of explosion.

Fact: Thorough discharge efficiency checked at higher level than running current makes it safer.

Myth: Refurbishment and replacement cost is same.

Fact: Refurbishment cost is always one-third cost of new battery.

Myth: Recycling is an eco-friendly process.

Fact: Recycling generates hazardous pollution, and thousands of workers and other people get cancer and other diseases due to recycling. Lead acid batteries recycling are highly hazardous in nature. Circular economy leads to refurbishment where increasing life is best option.

Myth: Li-ion batteries will replace all lead acid batteries.

Fact: Lead acid batteries are the cheapest and safe option because they are one-fourth the cost of Li-ion batteries. Li-ion recycling is a global concern while lead acid can be recycled in an eco-friendly way.

For more details, visit: www.voltaredox.com

Harinder Mohan Singh,

E-mail: support@voltaredox.com/vcare@voltaredox.com

Mobile: 9810635349/9650993990

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.