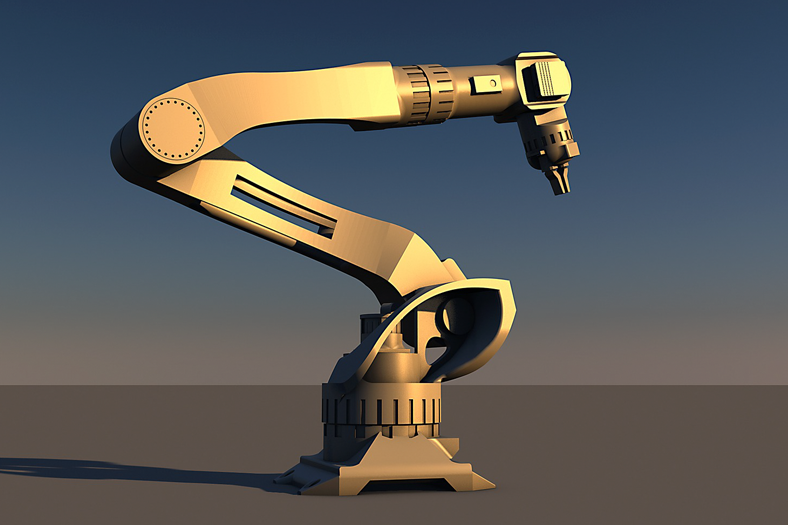

FANUC introduces collaborative arc welding robot at FABTECH 2019

By OEM Update Editorial December 16, 2019 12:10 pm IST

FANUC’s new collaborative arc welding robots offer the same high level of performance that FANUC ARC Mate robots are known for including world-renowned technology and proven reliability. A built-in sensor allows the welding cobot to work safely alongside people without the need for expensive guarding.

Easy to use – even for those who have never used a robot, FANUC’s arc welding cobots are equipped with FANUC’s Arc Tool application software. Arc Tool’s easy programming interface supports both simple and complex applications, including FANUC’s advanced features such as Weaving, iRVision, Seam Tracking, Thru-Arm Seam Tracking (TAST) and Multi-pass.

Both of FANUC’s new welding cobots provide six axes of motion for maximum flexibility. The CR-15iA for ARC offers a 15 kg payload and a 1441mm reach. The CR-7iA/L for ARC has a 7kg payload and 911mm reach. High payload capabilities combined with the large motion range increases system flexibility to process a broad range of parts.FANUC Cobots for ARC Features and Benefits

- Large motion range increases system flexibility.

- Easy setup and programming allows companies to respond quickly to customer demands.

- Built with the same quality and high performance as FANUC’s long-standing line of ARC Mate robots.

- Offers customers the unique ability to work closely with their welding processes.

- CR-15iA has a hollow wrist for seamless integration of weld package dress outs, third-party utilities, and sensor cables.

- Designed to meet the safety requirements of ISO 10218-1:2011 and RIA/ANSI R15.06-2012.

For more details, visit:

www.fanucamerica.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.