Promoting industrial safety and a safe workplace environment

By OEM Update Editorial March 30, 2024 12:37 pm IST

Girish Alawe, Dy. General Manager says tec.nicum, specialises in safety engineering and explains how tec.nicum’s technical safety inspections and consultancy services enhance workplace safety and compliance. Through comprehensive risk assessments and tailored solutions, tec.nicum provides a secure environment for machine operators worldwide.

In what ways tec.nicum is contributing to making the industrial world safer?

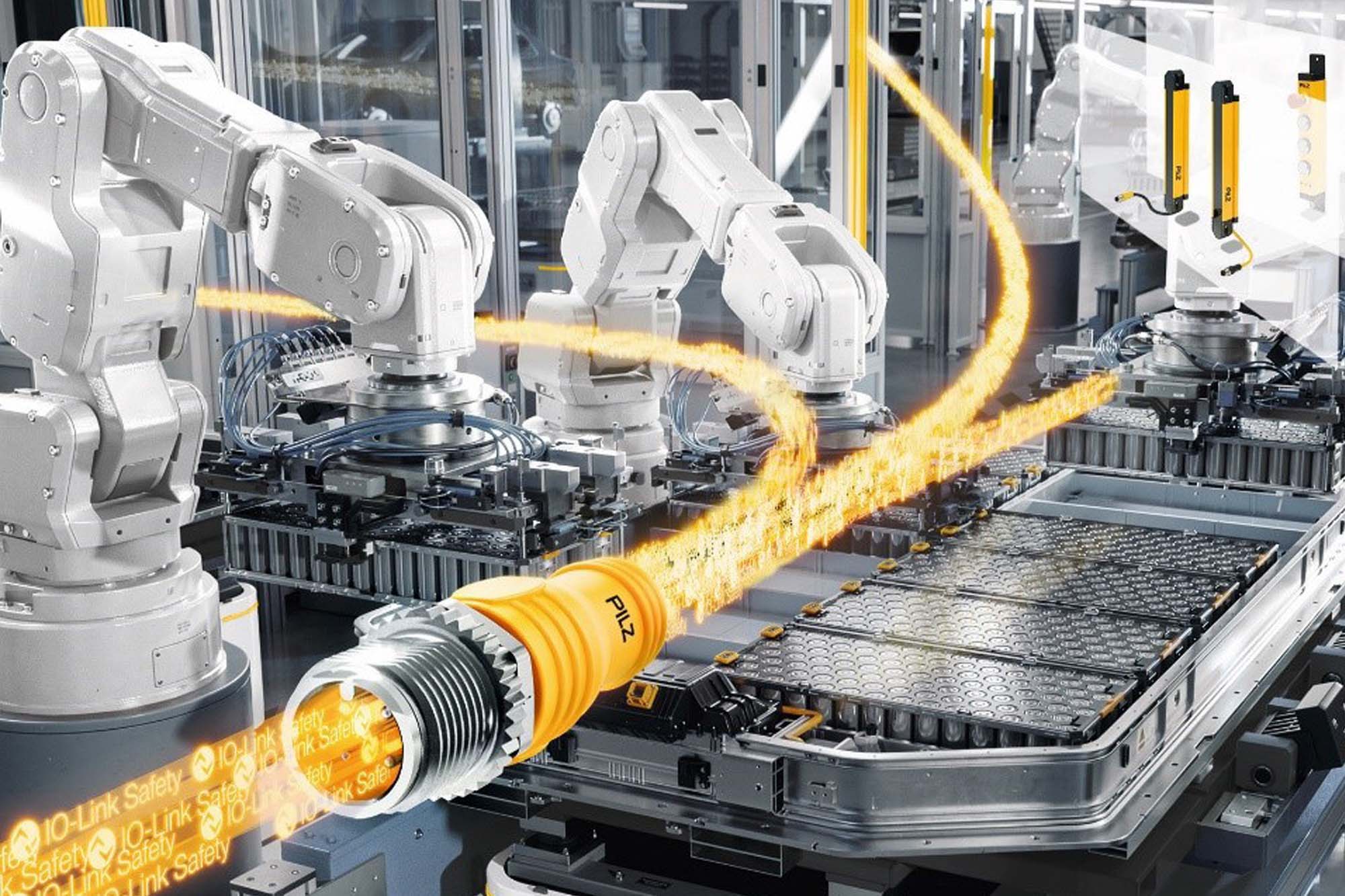

Machine safety is the basis for safe cooperation between humans and machines. It is a complex endeavour due to the many standards and guidelines involved. tec.nicum, part of the Schmersal Group, specialises in safety engineering and offers global consultancy through certified experts. tec.nicum’s core philosophy is to offer consultancy according to ISO standards, ensuring impartiality and objectivity, to devise the best possible safety solution for the individual application – true to the slogan: “Neutral approach everywhere.”

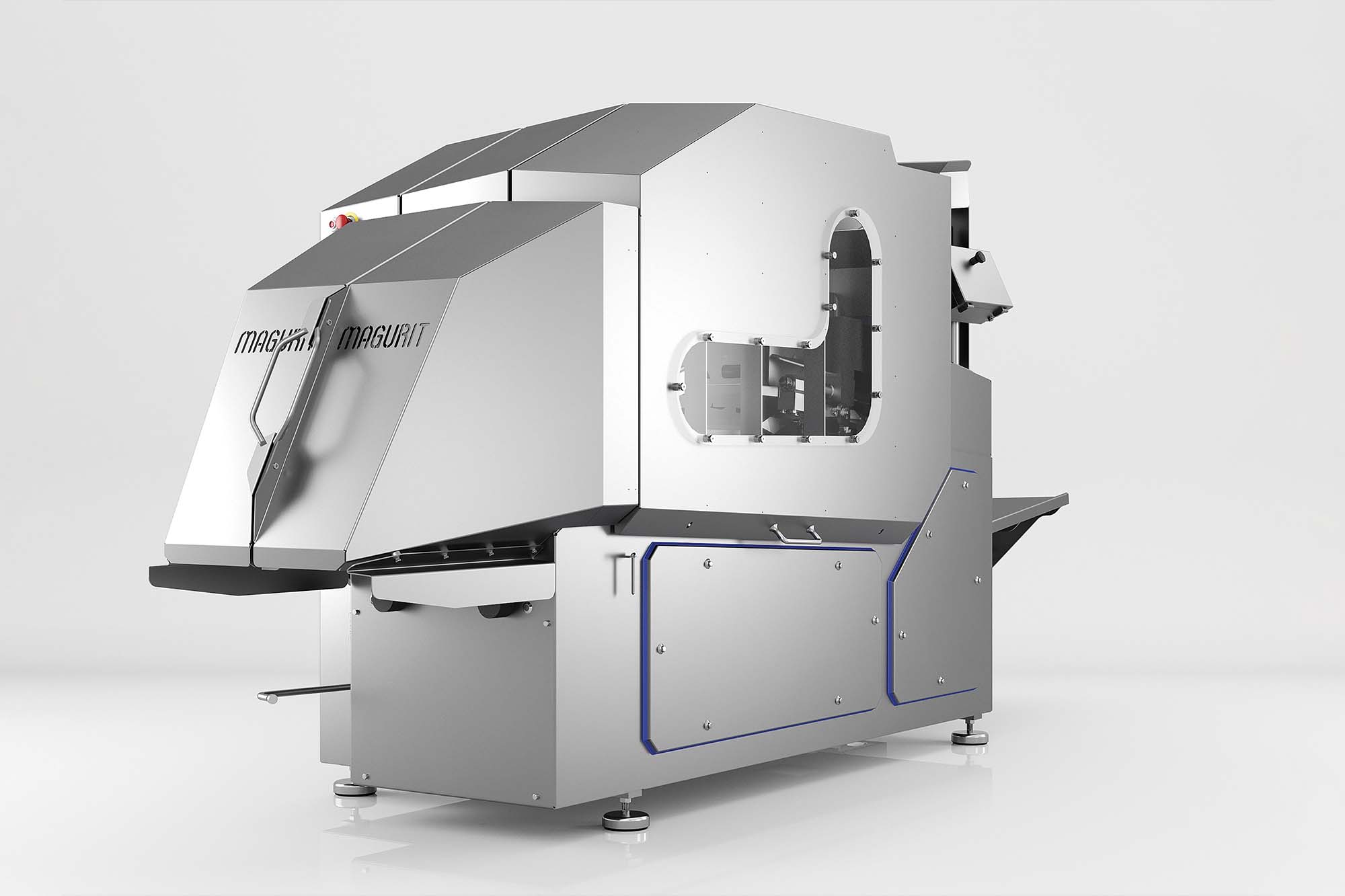

tec.nicum offers a comprehensive suite of services encompassing four key areas, which can be accessed as individual modules or as complete packages. The tec.nicum academy provides educational programs and awareness initiatives to enhance clients’ understanding of machinery safety. In consulting, tec.nicum conducts thorough assessments of machines, ensuring compliance with relevant legislation and standards while offering recommendations. In engineering, tec.nicum specialises in designing complete safety solutions, selecting appropriate safety devices and providing recommendations. Additionally, tec.nicum excels in integration, focusing on retrofitting older machines to upgrade them to achieve the maximum possible safety standards.

How do tec.nicum’ s risk assessment services for machine operators aim to improve workplace safety and health?

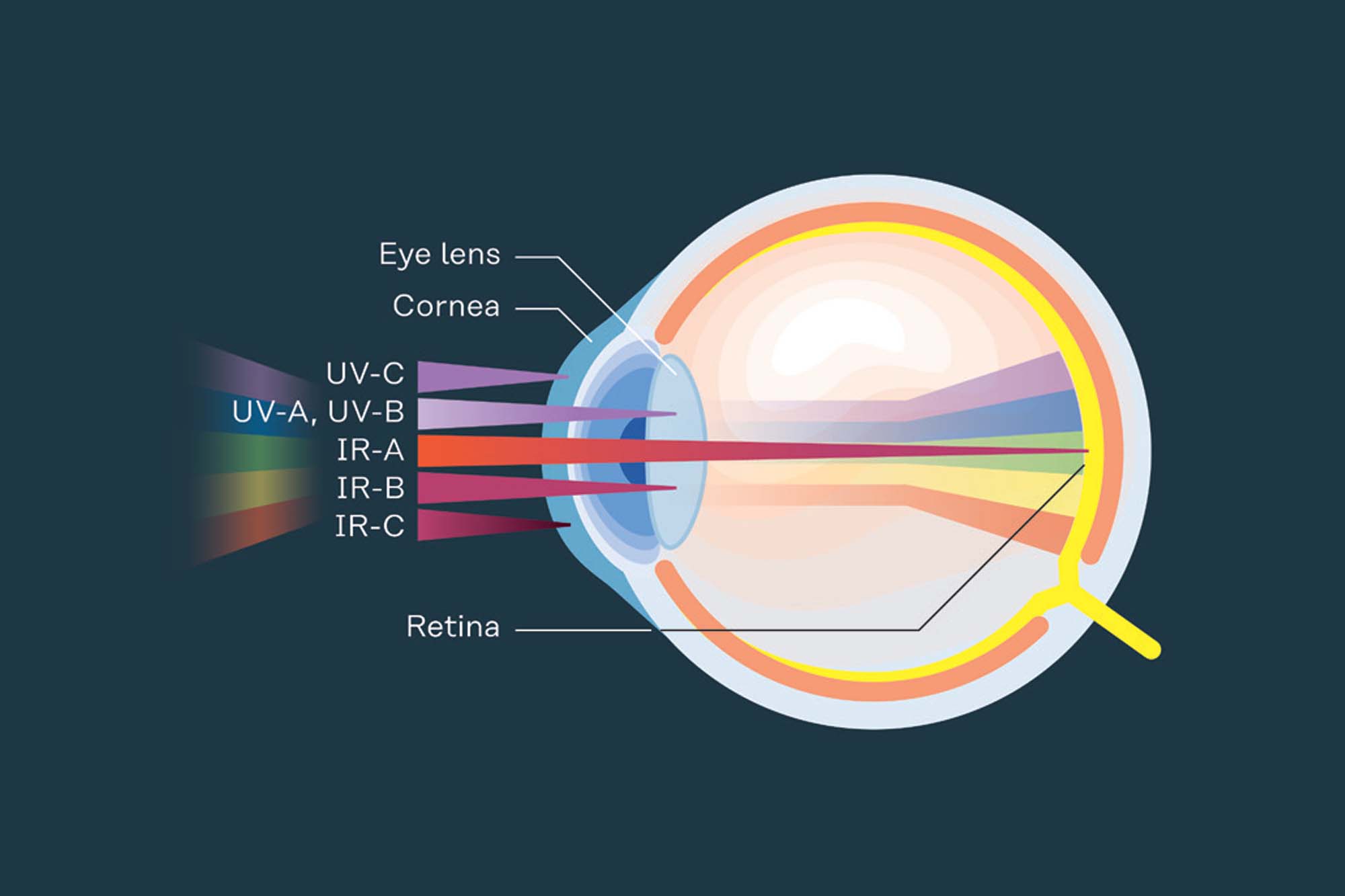

Our expert TÜV-certified safety consultants assess every stage of a machine’s lifecycle, including production, maintenance, and cleaning processes. They scrutinise machine operations across different modes such as automatic, manual, and jog mode, identifying hazards associated with various functions, ranging from mechanical and electrical to thermal, chemical, and noise-related risks. Subsequently, they compile detailed reports outlining each identified hazard, conducting comprehensive risk analyses, and offering tailored safety solutions to mitigate these hazards. Through our 360-degree approach, we ensure that a healthy and safe work environment for operators is created.

Could you provide examples of how tec.nicum’s technical safety inspections have helped improve the safety and compliance of existing machines and systems?

In regular practice, customers perform HIRA safety inspections, including general aspects of machine safety. Our risk assessment conducted by safety consultants prioritises adherence to safety standards and guidelines. This assessment focuses on analysing functional safety aspects, such as ensuring that safety products are fail-safe or normal, verifying proper wiring to safe control systems, and mitigating thermal, chemical, vibration, and noise hazards to appropriate levels. This approach guarantees that the machine poses no risk or injury to operators in the event of a safety component failure. Additionally, we examine mechanical guards to ensure they do not pose any hazard due to design flaws, and we verify that safety components like safety light curtains are placed at sufficient safe distances.What challenges do machine manufacturers face in maintaining safety standards in different regions worldwide?

Most machine manufacturers need to be made aware of other countries’ complete certification process, which leads to non-compliance. The requirements related to CE marking for Europe, NR-12 for Brazil, CSA for Canada are different and demand a lot of documentation to prove your machine safety compliances. Developing these documents and ascertaining machine safety are important in these compliances.

Please share some success stories where tec.nicum’s consulting and training services have improved machine safety and workplace conditions.

Tec benefits numerous success stories. nicum services, though we cannot specify any one. Across India, many customers have reaped the benefits of tec.nicum’s offerings. For instance, we have assisted clients in developing Safety Books to guide their machine suppliers. Additionally, for machine suppliers seeking to export to Europe, we have devised TÜV-recognised safety courses such as the Functional Safety Engineer (FSE) and Machinery CE Expert (MCEEXPERT). We have also provided practical training to understand the assessment process and craft safety circuits effectively. Those who have followed the right approach, like awareness, understanding of function safety, safe design engineering, risk analysis, mitigation & verification, benefit most.

How does tec.nicum support machine and plant manufacturers throughout their lifecycle phases, including technical support, evaluation, and risk assessment?

As mentioned earlier, functional machine safety is a complex topic that requires adherence to various safety standards and directives. tec.nicum provides comprehensive, product- and manufacturer-neutral consultancy services to machine manufacturers, operators, and distributors. We offer guidance on current statutory regulations and ensure that machines and workplaces are designed to meet relevant standards. From the initial stages of machine design to commissioning and ongoing assessments as per customer needs, we provide continuous support throughout the process.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.