Machine safety in the pharmaceutical and food industry

By Staff Report August 12, 2024 7:22 pm IST

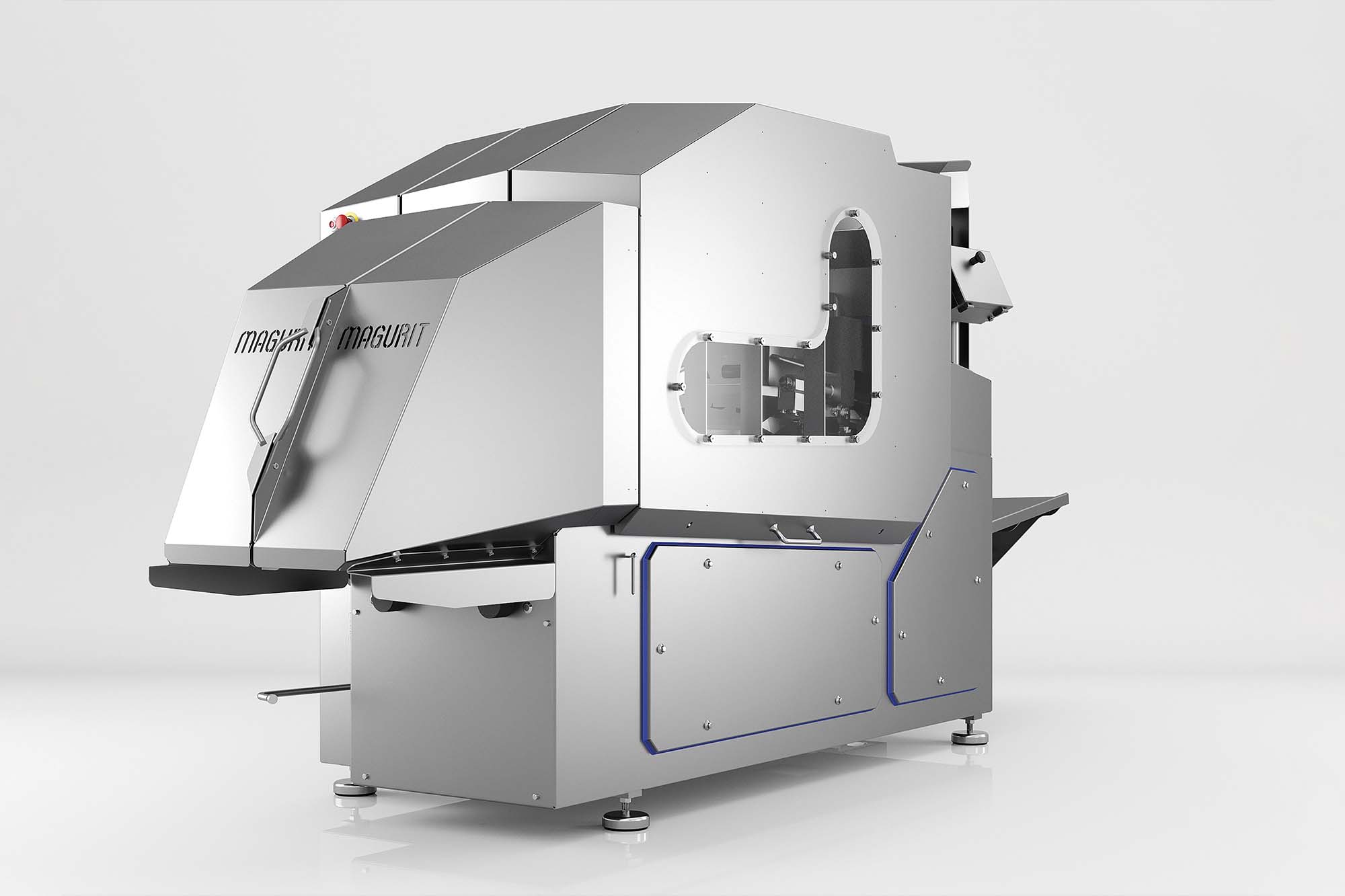

Food manufacturers use Magurit freeze cutters globally to cut frozen products safely. The company sets

standards in terms of quality, productivity, and machine safety. The components installed, such as safety switchgear, must also fulfil high standards. Requirements such as tamper protection and hygienic design are also added to this. This article discusses what is needed and what solutions are available.

Magurit Gefrierschneider GmbH provides machines that can cut frozen or fresh preliminary and final products, such as meat, fish, or fruit concentrates, into various forms like slices, strips, cubes, and pieces, according to the food manufacturer’s requirement. Based near Cologne, Magurit Gefrierschneider GmbH exemplifies the German engineering industry. Established in 1859, it has a long tradition and family ownership continuity running in its fifth generation. Magurit is the only specialist in the world, manufacturing machines designed to cut frozen raw materials in the food industry. It explains the ‘hidden champion’ export ratio of around 80 percent.

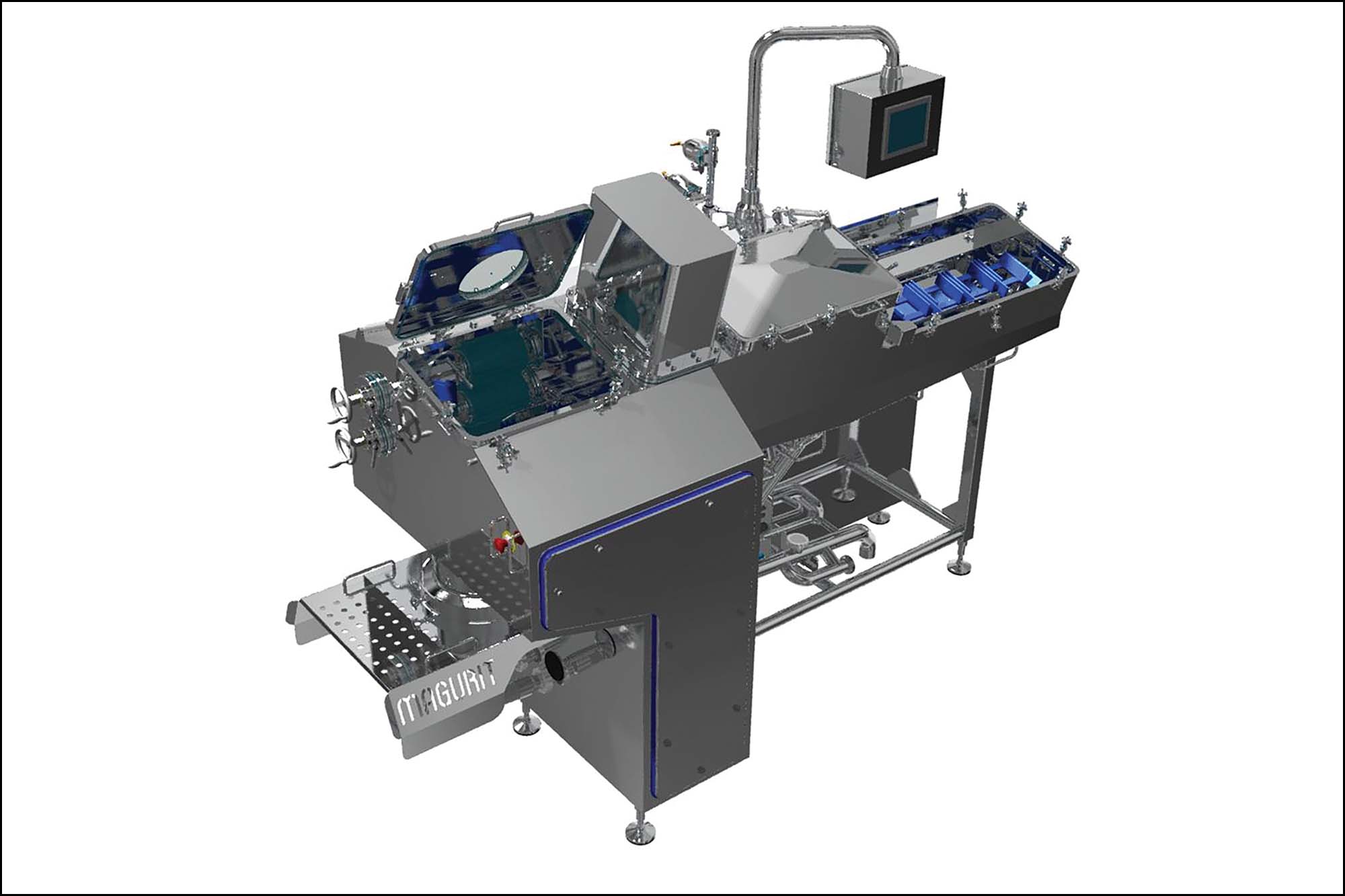

Magurit is constantly developing new applications and technologies. The most striking example is probably the development and production of freeze cutters for the pharmaceutical industry. These machines process frozen blood plasma, a valuable ingredient for many medicines. Magurit designs and builds sophisticated, customer-specific systems in accordance with the complex rules and regulations of pharmaceutical production and even stricter hygiene regulations than those in food processing.

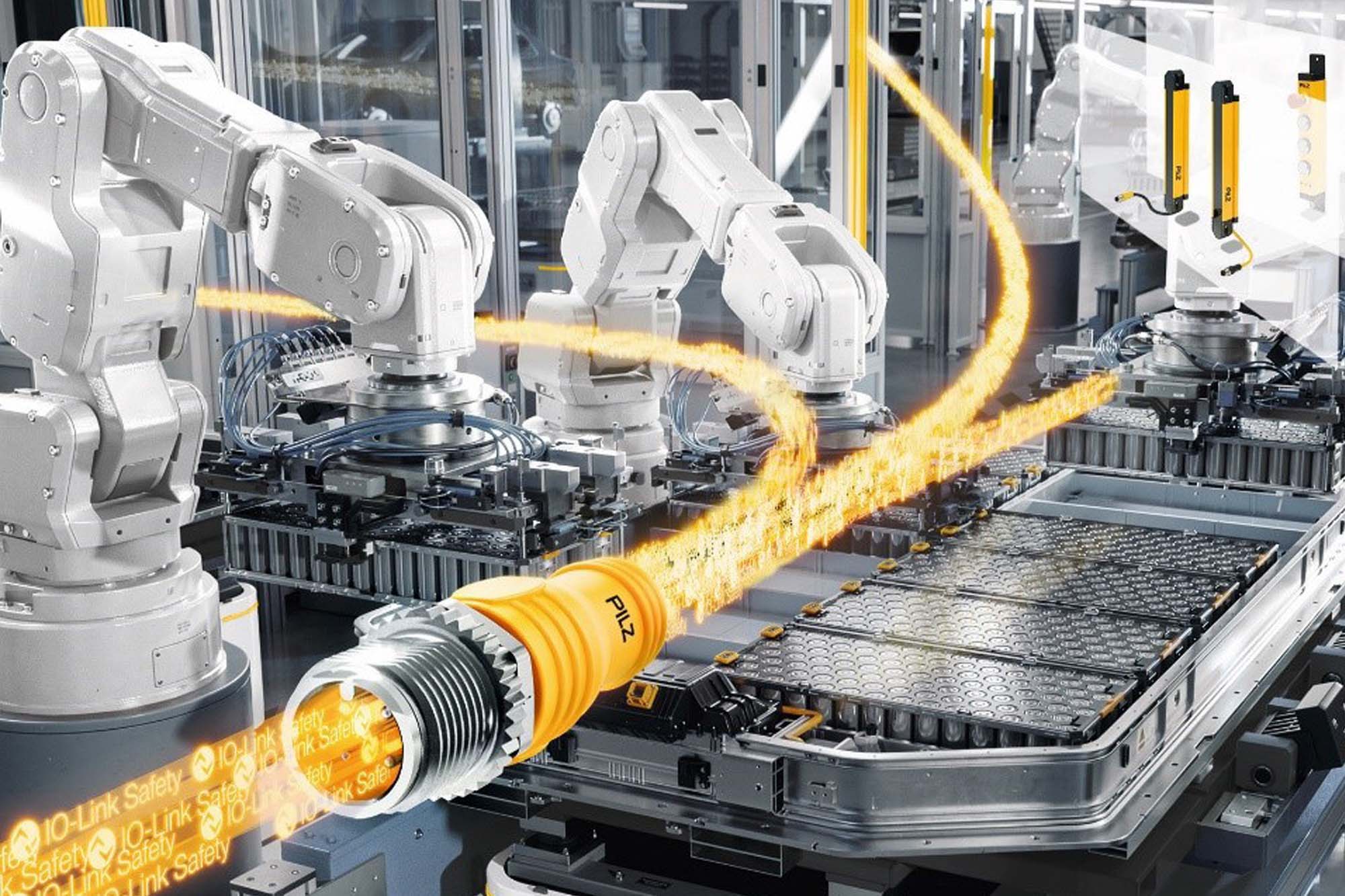

Machine safety: continuity and innovation

The company relies on continuity and innovation in machine safety. It has maintained continuity in partnership with Schmersal for several decades and has a cooperative commitment to innovation by selecting advanced safety switching devices and signal evaluation systems. This is demonstrated using the Protect Select OEM compact safety controller from the Schmersal range across all series.

Safety controller: Customised and compact

The Protect Select series by Schmersal bridges the gap between standard safety monitoring modules available on the market and a fully-blown safety controller. It was developed for manageable applications, i.e., for up to five safety functions, and the user does not have to do any programming. Instead, the user selects one of several preconfigured application programmes and defines the desired parameters—input assignment, debounce, and drop-out delay times—via menu navigation and plain text display.

Safety compact control unit in customised version

Magurit has been using a customised version of the safety modules for around 25 years and is maintaining this strategy for the compact safety controller. The Protect Select OEM from Schmersal allows customers to specify the desired functions, and a fully programmed control unit is available. The advantages offered by this concept of safety-related signal evaluation are manifold.

Dipl.-Ing. Managing Director of Magurit, Dino Vieth says, “We now use a standard safety controller across the series according to the ‘one for all’ principle, in which we can activate the required functions in each case. This control system is validated, and we select which features are required. It is easier than using different combinations of safety modules as before.” And the system remains flexible.

Smooth changeover

Dino Vieth said the changeover from the relay modules to the customised compact safety controller went smoothly. The safety experts from Schmersal provided good support and understood our requirements. We have also worked well with Stollenwerk as Schmersal’s representative for many years. In addition to the technical advantages, there is also a commercial benefit.

Dipl.-Ing. Uwe Stollenwerk, Technisches Büro Stollenwerk GmbH says, “If a Protect Select replaces two or more relay modules – and this is often the case with Magurit machines – the user also saves costs.Safety sensors: The art of hidden installation

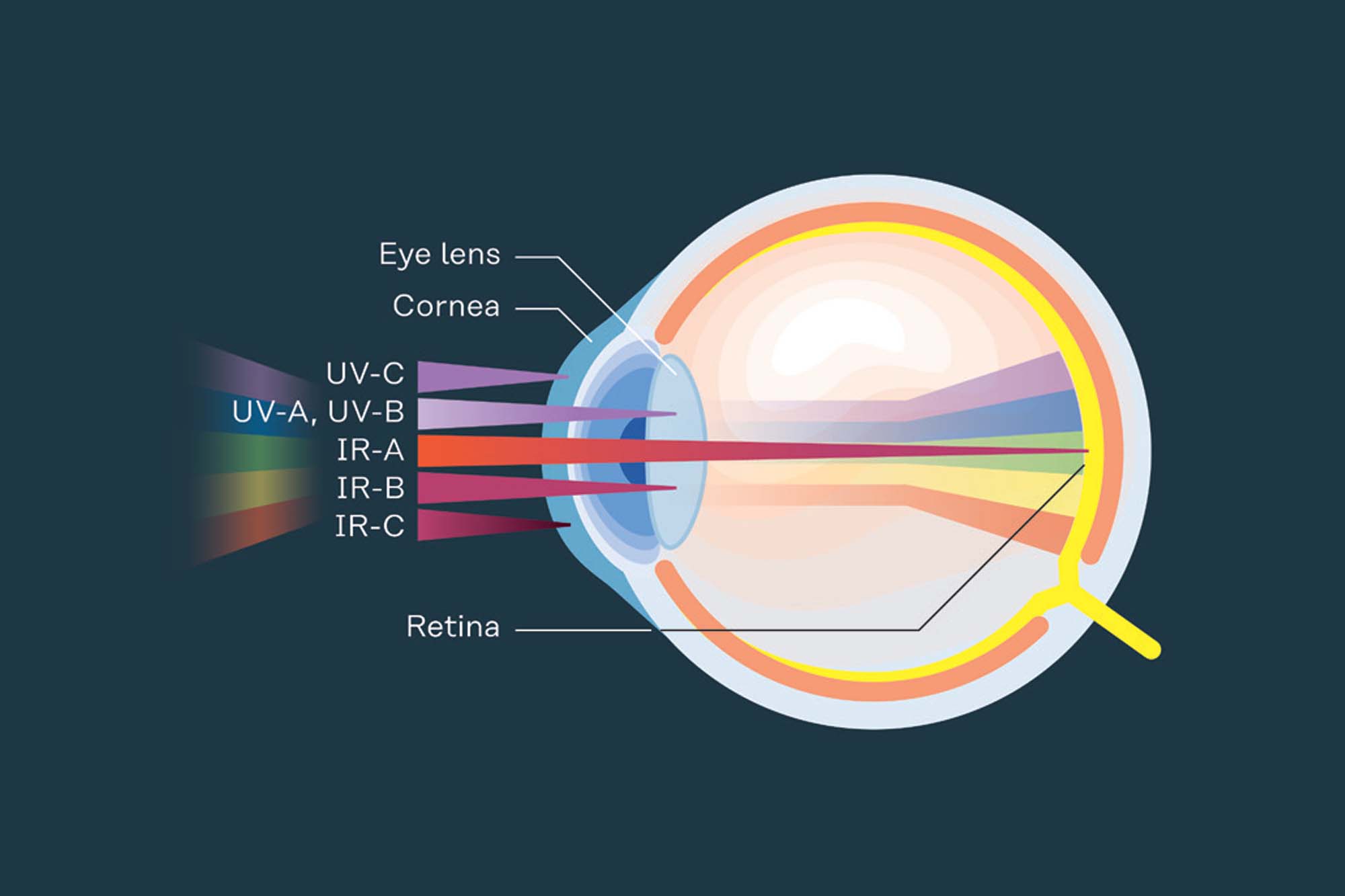

A well-thought-out solution is used to monitor the position of the safety doors and protective hoods that safeguard the danger zone of the cutting unit. As the hygiene requirements for freeze cutting are very high, Magurit uses non-contact safety magnetic sensors. These sensors are concealed behind a stainless steel cover. The associated uncoded actuating magnets are hidden in the stop buffer of the protective cover. In practice, this effectively prevents the risk of tampering to bypass the safety guard or render it ineffective.

Uncoded magnets are used because safety sensors with coded magnets have such a small switching distance that strong vibrations – which cannot be avoided during freeze-cutting – can cause the machine to switch off. If this risk can be ruled out, Magurit also uses open-mounted safety sensors with coded magnets.

Operating elements with a high standard of hygiene

The man-machine interface of the freezer slicers must meet high hygiene standards addressed by Schmersal’s N programme. These command and operating devices follow ‘hygienic design’ principles, featuring optimal sealing, easy cleaning, and the absence of dead zones where product residues or liquids could settle. The program ensures operating functions can be mapped hygienically.

Dino Vieth says, “We use this programme for simpler machines that do not require a touch panel or as a supplement to the touch panel— and of course for the obligatory emergency stop button.”

A change is imminent. Schmersal has introduced a new series of operating and command devices, the H series, which will replace the N series after more than 25 years and which Magurit will use in future. The advantage of the new H series is that it meets the requirements of DIN EN ISO 14159, an innovative version of EN 1672-2 and the new regulation 10/2011/EU. In addition, the H-Series has a modular design and is therefore very flexible.

Multifunctional

The parameterisable Protect Select compact safety controller in its OEM version is more versatile and flexible than standard safety modules. It is utilised across all Magurit series and offers numerous programming options, allowing flexible and adaptable solutions customised to the applications.

For more detail, visit: Schmersal India Pvt. Ltd.

www.schmersal.in, www.tecnicum.com

Source: INDUSTRIELLE AUTOMATION 2024/04,

www.industrielle-automation.net

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.