Electrical safety in a compressor room

By Staff Report August 9, 2024 6:47 pm IST

Chicago Pneumatic Compressors focuses on strict safety checks and precautions. Given the high-risk nature of the equipment and processes, ensuring electrical safety in manufacturing and HVAC systems settings is vital. This article delves into the importance of electrical safety in compressor rooms and outlines the prerequisites to maintain a safe and efficient operation.

Compressor rooms are integral to various industrial and commercial operations, providing essential services in manufacturing, HVAC systems, and more. Ensuring electrical safety in these environments is critical due to the high-risk nature of the equipment and processes involved. Chicago pneumatic compressors adhere to all the electrical safety checks in the compressor room, and necessary precautions are adopted while commissioning the compressed air systems.

Electrical Safety: Preventing electrical hazards

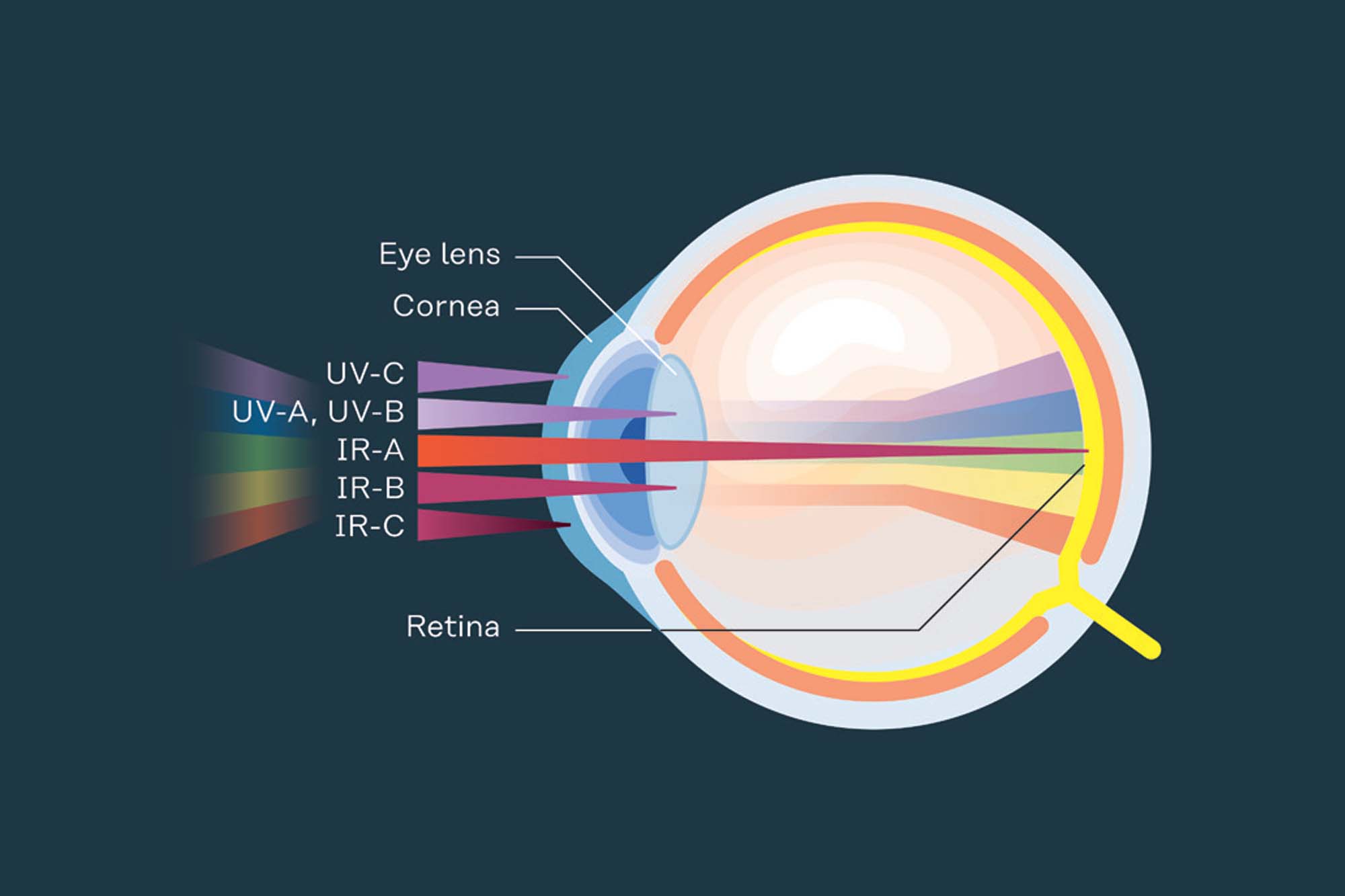

Electrical safety is a fundamental prerequisite to prevent electrical hazards as the risk of electric shock is prominent. Compressor rooms often house high-voltage equipment. Proper insulation and grounding are vital to resist electric shocks, which can be fatal. The fire hazards can lead to electric fires due to faulty wiring, overloaded circuits, and short circuits. Ensuring that all electrical components comply with codes and are regularly inspected reduces this risk.

Protecting equipment and infrastructure

Protecting equipment and infrastructure is necessary for maintaining the longevity and efficiency of operations. Electrical surges and faults can damage compressors and machinery, leading to costly repairs or replacements. Implementing safety measures helps prolong the lifespan of equipment.

Additionally, electrical safety helps maintain operational continuity. Electrical failures can halt operations, causing downtime and productivity losses. Ensuring electrical safety minimizes the risk of such interruptions.

Compliance with regulations

Compliance with regulations is essential for maintaining electrical safety in compressor rooms. Electrical safety in compressor rooms is governed by various standards and regulations, such as the National Electrical Code (NEC) and Occupational Safety and Health Administration (OSHA) guidelines. Compliance warrants legal operation and avoids penalties.

Regular safety audits and inspections by regulatory bodies require adherence to electrical safety standards. Proper safety protocols ensure smooth passage through these evaluations.

Electrical safety in compressor rooms

Proper installation and maintenance are prerequisites for electrical safety in compressor rooms. Certified electricians must install electrical systems in compressor rooms. This ensures adherence to safety standards and reduces the risk of errors.Additionally, routine inspection should identify and rectify potential electrical hazards. It includes checking wiring, circuit breakers, grounding systems, and the overall condition of electrical components.

Quality equipment and materials

Quality equipment and materials are crucial for electrical safety in compressor rooms. All electrical equipment used should be certified and meet the required safety standards. Using substandard components can increase the risk of electrical failures. Further, proper insulating materials and grounding systems must be high quality to prevent electric shocks and other hazards.

Safety protocols

Safety protocols are essential for maintaining electrical safety in compressor rooms. Implementing lockout/ tagout procedures ensures that machinery is properly shut off and cannot be restarted during maintenance, preventing accidental electrical injuries.

Further, compressor rooms should be equipped with emergency shutdown systems to cut power in an emergency.

Training and Awareness

Training and Awareness are critical components of electrical safety in compressor rooms. Regular training sessions should be conducted to educate employees about electrical safety protocols and emergency procedures. It ensures that everyone in the compressor room knows about potential hazards and how to respond appropriately. Moreover, clear and visible safety signs should be placed around the compressor room to alert personnel to electrical hazards and emergency procedures.

Electrical safety in compressor rooms is necessary to safeguard the well-being of personnel, the longevity of equipment and the continuity of operations. Creating a safety culture through training on the risks associated with electrical hazards can be mitigated. Prioritizing electrical safety safeguards lives and enhances the efficiency and reliability of compressor room operations.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.