Automation with effective communication and diagnostics

By Staff Report October 7, 2024 6:55 pm IST

Pilz enhances industrial automation with secure, reliable communication and diagnostics between machines, sensors, and control systems. Through technologies like IO-Link Safety, PSSuniversal, and SecurityBridge, Pilz promotes safety and protects critical assets in manufacturing.

The manufacturing industry is updating itself with smart technologies, making automation essential for efficiency, precision, and consistency. With data-driven processes, the safety and reliability of automated systems are crucial. Robotics and AI enable unprecedented precision and speed, allowing continuous operation with minimal downtime. Machine learning enhances predictive analytics, reducing equipment failure risks. Safety in manufacturing protects workers and machinery, especially in hazardous environments. Automation reduces human intervention but can lead to large-scale failures. Thus, safety measures must be integral to automated systems, ensuring safe shutdowns during malfunctions to prevent further harm.

Automated systems need reliable communication modules for realtime hazard detection and response. These modules enable immediate intervention during malfunctions, using sensors and networks to trigger shutdowns or alerts. Robust communication integrates safety protocols, ensuring synchronised and swift action in emergencies. Without adequate safety measures, a single malfunctioning unit or disrupted control system can lead to costly downtimes, accidents, or even fatal injuries. Thus, safety is essential for maintaining trust, especially in high-stakes industrial environments.

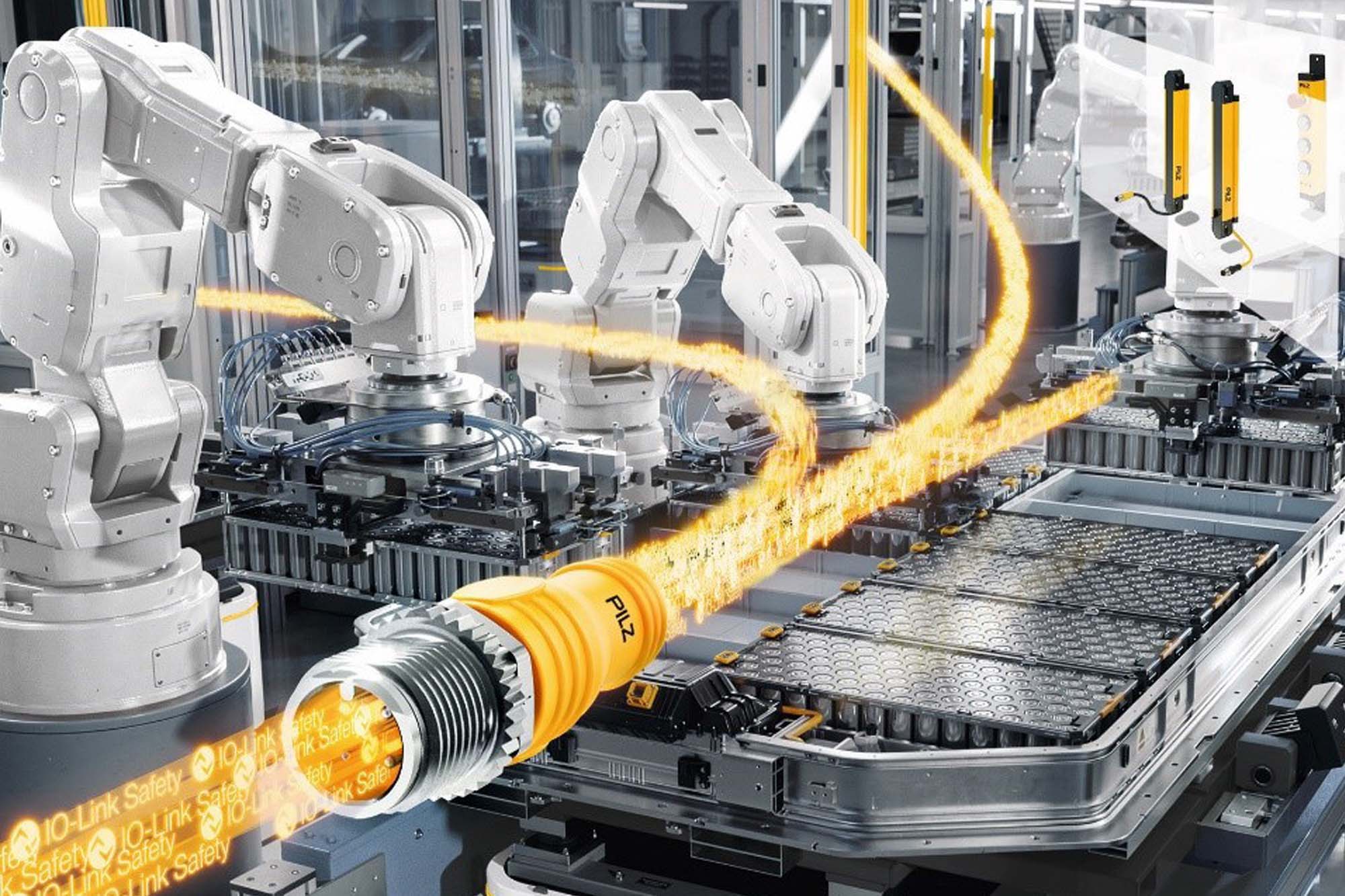

Effective communication and diagnostics are essential in industrial automation manufacturing. They ensure seamless interaction between sensors, control systems, and machinery to maintain safety and productivity. A key component of Pilz’s safety solutions is IO-Link Safety, a technology designed to facilitate secure and reliable communication between field-level sensors and centralised control systems.

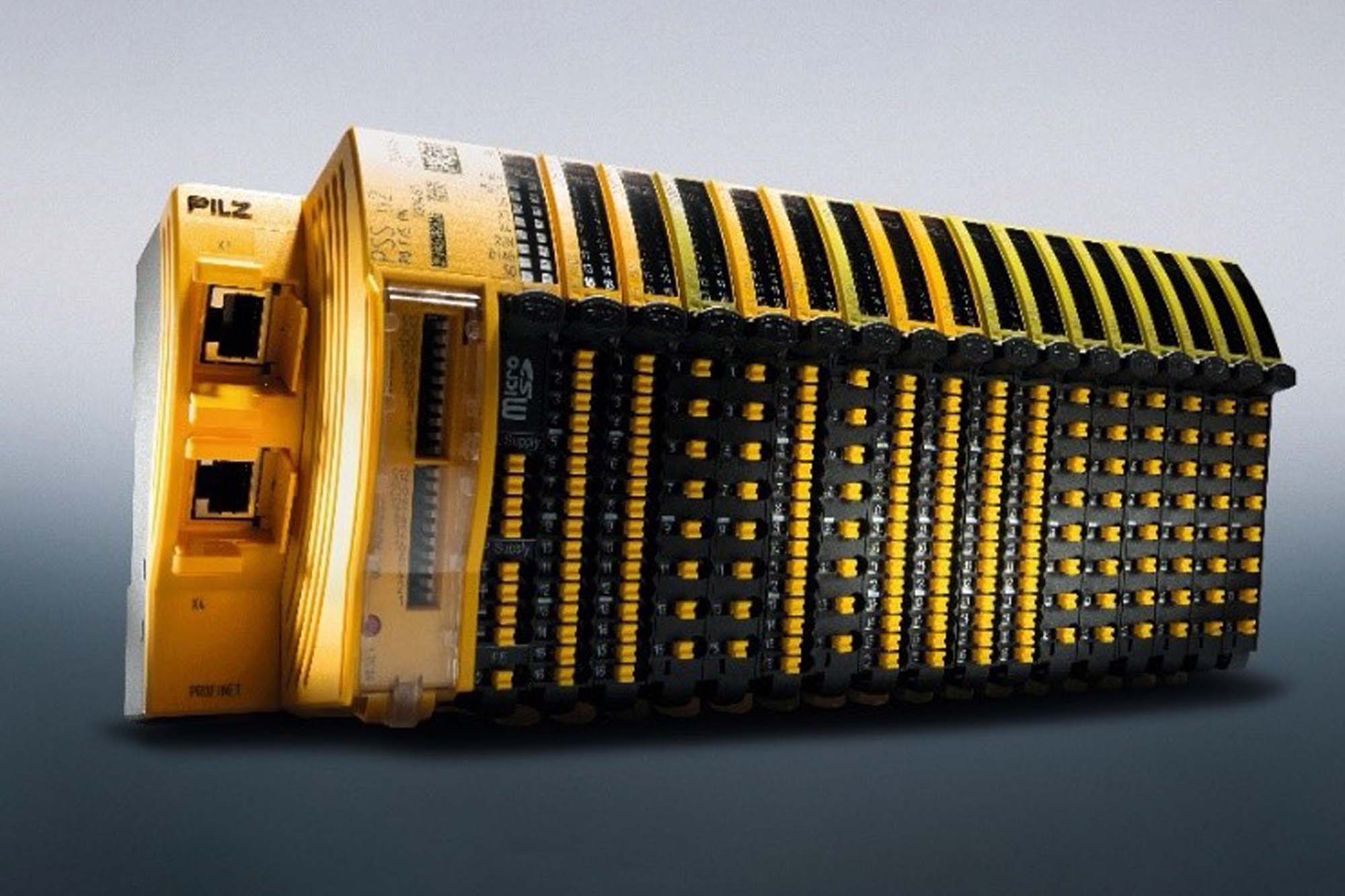

IO-Link Safety can connect multiple sensors and actuators, ensuring real-time data exchange across various machines and devices. This connectivity is important in large manufacturing environments, where machinery and systems must operate together to avoid delays or disruptions. By streamlining communication between sensors and control systems, Pilz ensures that critical safety data is transmitted quickly and accurately for immediate intervention when potential hazards are detected.In addition to IO-Link Safety, Pilz offers solutions that enhance the decentralisation of control across the plant floor. Products such as the PSSuniversal 2 I/O module and the PSS67 decentralised I/O module provide increased flexibility and reduce the wiring complexity in industrial environments. This module is designed for harsh environments, offering real-time data processing and redundancy to ensure uninterrupted operations even in the most challenging conditions. On the other hand, the PSS67 decentralised I/O module, which boasts an IP67 rating, is built for installation directly on machinery. This eliminates the need for large control cabinets and reduces wiring complexity, ultimately lowering installation costs. The ability to place control modules closer to the actual machinery enhances the flexibility and safety of the overall system. Manufacturers can maintain safety across their plant floor while simplifying maintenance by decentralising control.

Diagnostics of machines is a crucial factor in industrial automation, ensuring that all safety components function correctly and efficiently. Pilz’s diagnostic tools such as Safety Device Diagnostics (SDD) provide real-time and extensive diagnostics to avoid service operations and to reduce downtimes, remote diagnostics via web server is one such example. This proactive approach minimises downtime and enhances overall system reliability, ensuring that safety protocols are always upheld. By integrating robust diagnostics, manufacturers can maintain a secure and productive environment, preventing accidents and ensuring continuous operation. The interconnected nature of modern industrial systems means that any vulnerability in the network could be exploited by malicious actors, leading to unauthorised access or data breaches. Pilz offers the SecurityBridge firewall, which protects industrial automation networks to mitigate these risks. The SecurityBridge can be connected to control systems such as the PNOZmulti 2 base unit or the PSSuniversal PLC. Only authorised users can access and modify system configurations, preventing unauthorised access to critical control systems. Data transmission between the client PC and the SecurityBridge is encrypted, making it secure from eavesdropping or manipulation. Pilz developed the SecurityBridge in compliance with IEC 62443-4-1, a standard for secure development processes for industrial control systems.

By ensuring that communication and data diagnostics between manufacturing machines, sensors, and control systems are secure and reliable, Pilz enhances the safety and security of manufacturing processes while safeguarding human lives and critical assets. Pilz remains committed to driving innovation in safety technologies as the manufacturing industry continues to evolve, ensuring that manufacturers can harness automation without compromising safety or security.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.