Svaya Robotics develops all in-house collaborative robots with AI and ML integration

By Staff Report November 30, 2024 5:32 pm IST

Svaya Robotics develops collaborative robots with AI and ML integration all in-house. These robots enable manufacturers to adapt to changing demands, enhance productivity, and ensure secure, autonomous operations with easy-to-use interfaces and zero-maintenance reliability.

What are the major challenges manufacturers face, and how does Svaya Robotics address them with its solutions?

I feel the major challenges faced by manufacturers are the constantly changing market demand for product variety and volume. Manufacturing units traditionally implementing fixed automation, such as special-purpose machines and gantries, do not address the above concern. Production requires an interplay of humans and robots to be adaptive, precise, and more productive. The solution to the problem is flexible robotic automation, and we at Svaya Robotics offer collaborative robots with a patented user-friendly interface that helps address the industry’s concerns, both new and existing setups.

SCADA systems, PLCs, HMIs, and connected IoT devices can be at risk. How do you protect the same at your manufacturing unit?

The manufacturing industry has widely adapted to interconnected and remote-controlled devices for programming, troubleshooting, and preventive maintenance, introducing risks like data breaches and unauthorised access. At Svaya, we address these risks through secure network segregation. To limit exposure, We keep all critical systems like SCADA, PLCs, and IoT devices on separate, secured networks. We also maintain robust and regularly updated firewall protection, monitor for threats, and train employees on data security best practices. Combined with timely system updates, this layered approach ensures the safety of our operations and sensitive data.

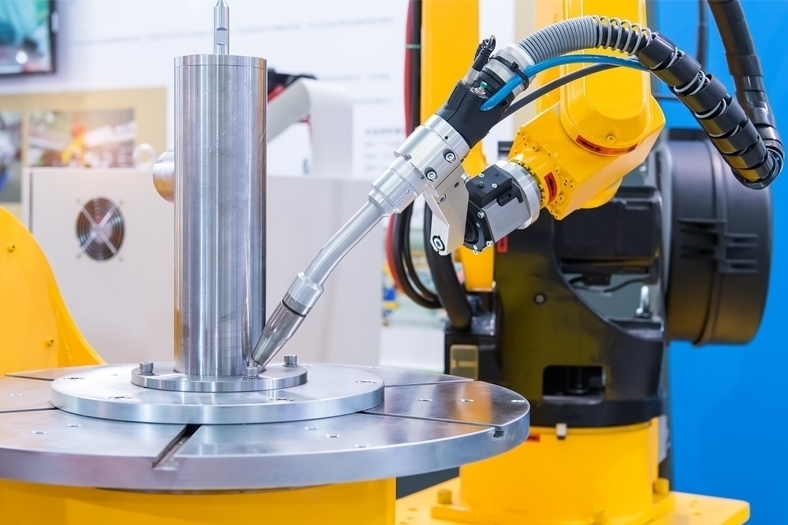

How does your SR-L Series assist the manufacturers in easing their operations?

Our SR–L collaborative robots are simple to integrate into any setup without retrofitting. Line workers can drive integration and day-to-day operation on the job through its easy-to-use no-code interface. They are convenient for quickly changing between tasks with little or no downtime, even as production demand changes. They are reliable and can work day in and day out with zero maintenance for the life of the robots.How has the incorporation of Al and ML improved your solutions?

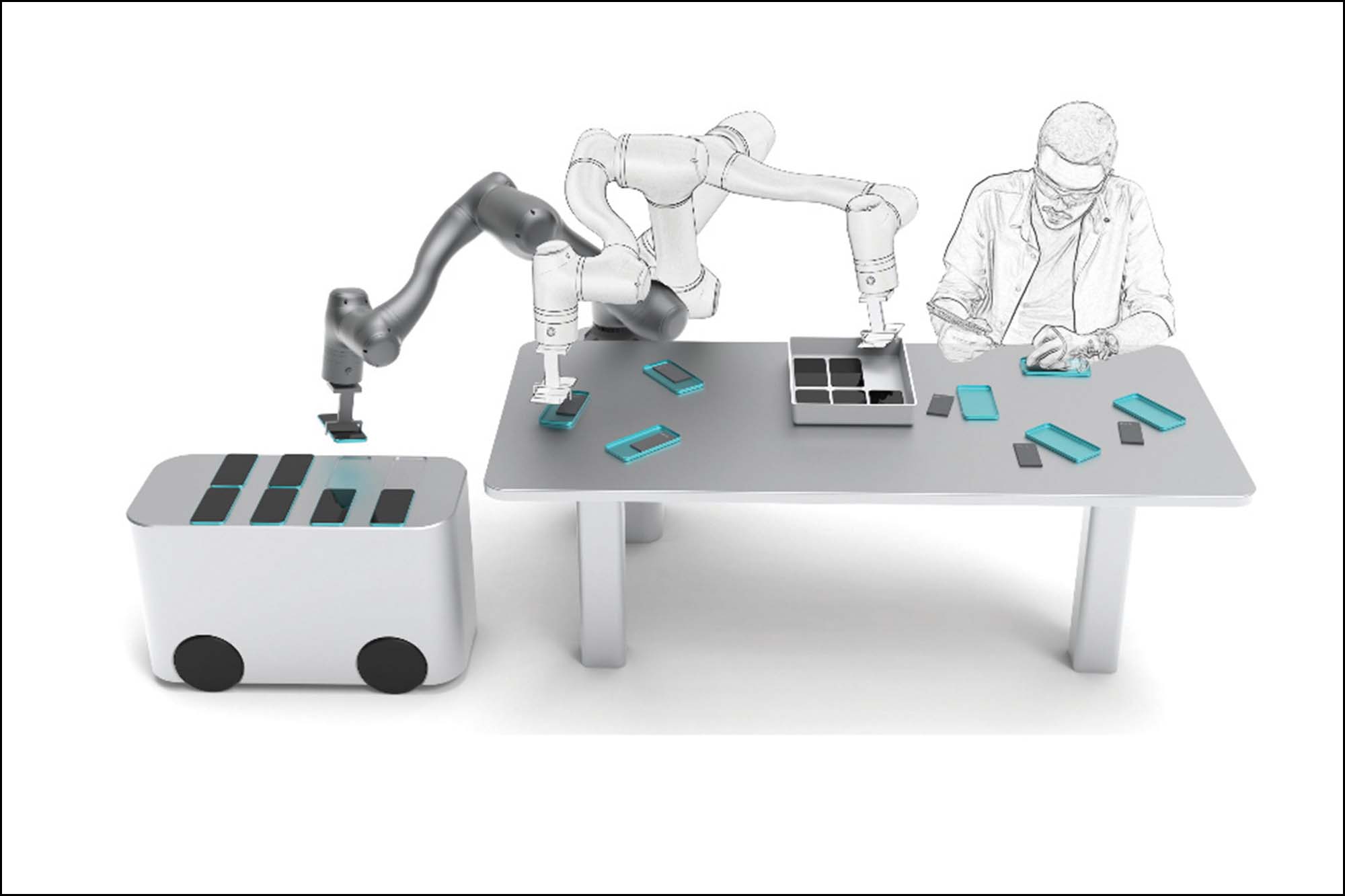

We enable adaptive and agile working by allowing manufacturers to quickly adjust to changing production demands and environments. With advanced tactile perception, integrated vision and AI, our cobots can dynamically adapt their actions to task variations or unforeseen conditions without requiring manual reprogramming every time. This flexibility allows manufacturers to scale operations, easily switch between tasks, and respond rapidly to workflow changes while maintaining high efficiency and precision. By continuously learning and adapting, our cobots empower you to shape “your work your way,” tailoring operations to meet production needs and enhancing agility.

How does Svaya Robotics develop its robots, and what advancements are being made in autonomous capabilities and AI integration?

Svaya robots are completely developed in-house. Our full-stack vertical integration helps us develop robots of different form factors, including 6-axis, 7-axis, and Dual-Arm Robots. We are deeply investing in developing autonomous capabilities in robots powered by AI and advanced perception. AI-powered Svaya Robots can learn from human experience and the data they see and gather in their work and actions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.