Human-Robot environment a positive step ahead

By OEM Update Editorial March 7, 2019 5:48 pm IST

NS Madhusudhanan, Senior Manager-Robotics Business Development, Factory Automation & Industrial Division, Mitsubishi Electric India Pvt Ltd in an interaction with Aultrin Vijay of OEM Update, Madhusudhanan shares his views and expertise in the field of robotics.

What products or solutions were launched/displayed at IMTEX 2019?

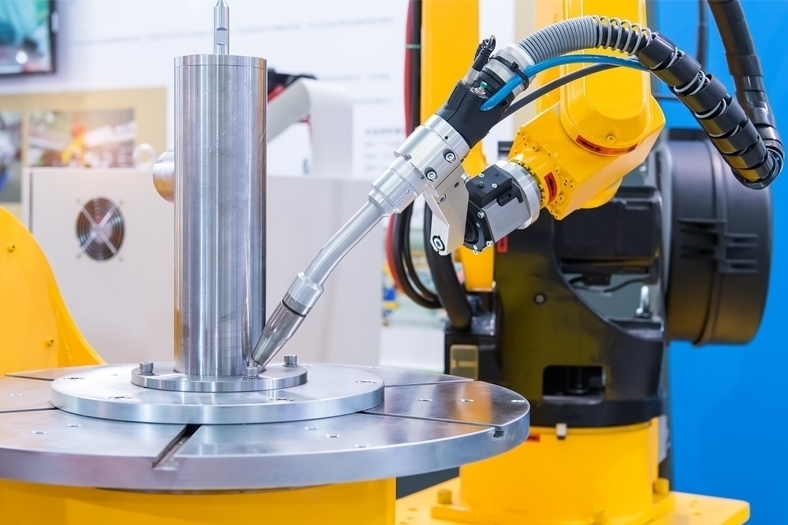

Mitsubishi Electric has introduced collaborative robots with efficient inspection system this year at IMTEX, apart from the other conservative robots which we call as FR Series Robots. The other robots have been combined with CC-Link IE Basic — a communication protocol, which helps them communicate with field engineering systems. You would be able to communicate with a single LAN cable so that the data gets communicated from the robot to the systems. This makes wiring easy, so it’s one of the USPs we have in our robots.

The collaborative robots are equipped with an LED on the arm itself, which can dynamically notify the status of the robot. So, when the robot is on move, it signals green. If there’s an error, it shows red. This helps us to understand the condition of the robot in real-time.

When we say collaborative robot, a human always interact with the robot and the system gets collaborative. For us, at Mitsubishi Electric, making the systems collaborative is more important.

Tell us a bit more about the collaborative robots

There are some modules in the collaborative robots where you can move the robot with your bare hands and “teach” that point through the arm itself. So, any layman can logically do this programme. That is what we call as “the easy way of robotics”. This especially helps, if you are doing a pick-and-place or an assembly application and omits the need to write a lengthy programme. So you can just move the robot from one point to another point and you can just “teach” it. That is more important in the collaborative systems.

At Mitsubishi Electric, we take human safety seriously. So, the collaborative system is also more important. For example, if somebody goes near the robot it should automatically stop or slow down so that machines can work along with humans without any problems.

Also, if somebody has an old robot of Mitsubishi Electric make, we can also make it collaborative.

Will it have the ‘price’ appeal that the Indian customers are looking for?Collaborative robots can be used to replace manpower where repetitive or fatigue tasks are involved. I think we can match in terms of cost vs productivity. Our robots have industry standard pricing, but in some cases you need to pay extra for additional options or features. For example, you need to pay extra premium for Artificial Intelligence applications such as preventive maintenance, which is useful for a lot of industries. However, the extra cost serves a very good purpose and it’s not costly when compared to the robot’s capital cost. I think we are almost trying to match the industry standard pricing.

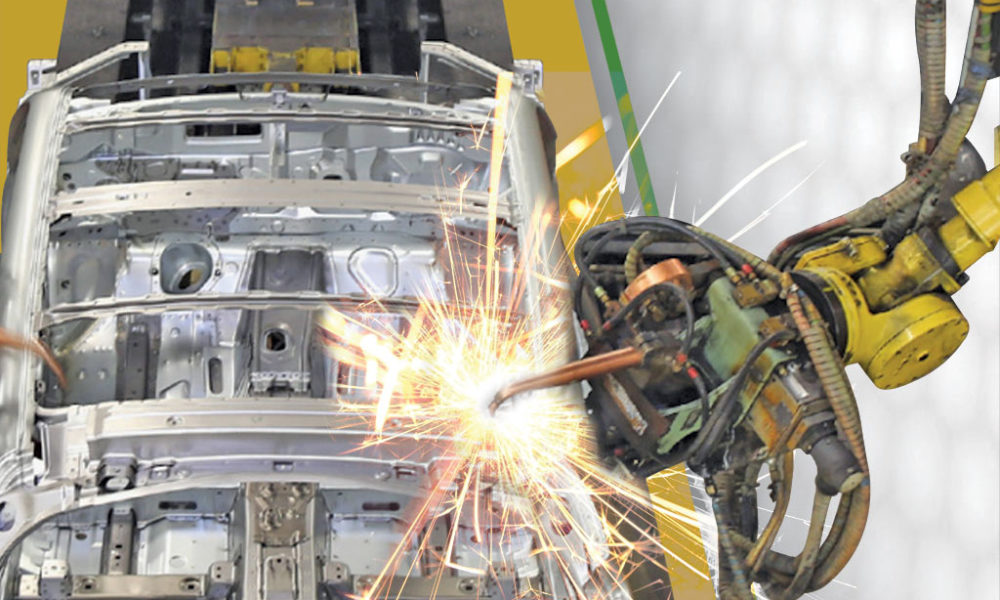

Will robots work alongside humans or would it be taking away their jobs?

Actually, replacing of humans is a myth. It is not true. It is just that we are moving from one level to the other. Earlier, to operate a CNC machine, we needed an operator. With robots, we are trying to improve the operator’s efficiency and take him to the next level. So it’s not taking away any jobs. The operator needs to be educated to use the machine and his life will become easier. That means, the same operators can be utilised to understand the high-end system. That’s all! So, it is not absolutely going to replace humans. It is going to use the manpower for other productive tasks instead of doing repetitive tasks. No company would like to use its manpower to do fatigue intensive tasks.

Talks about India adopting Industry 4.0 has been going around for a long time. Still, no factory in India is 100 per cent Industry 4.0 complaint. Why do you think that’s happening?

Talking about Industry 4.0, we have coined our own term: e-F@actory. We have already started implementing e-F@ctory and we are educating all our existing customers, too.

India is a growing economy and we have moved from the traditional machining systems to an automation platform now. Next, we want to get into the collection of data platform. However, collection of data will only become big garbage. Industry 4.0 needs to be understood thoroughly in order to get things correctly.

I think Mitsubishi Electric is doing well in e-F@ctory by providing turnkey solutions to the customers. The response from our customers has been encouraging so far.

Robots will not take away jobs. Instead, they will work along with humans to provide an easy working condition

NS Madhusudhanan, Senior Manager-Robotics Business Development, Factory Automation & Industrial Division, Mitsubishi Electric India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.