Golden rules of BUYING HAPPY ROBOTIC SYSTEMS

By admin August 19, 2011 5:48 am IST

“When you buy robotic system you are not buying a product as a robot but buying a system or function which consists of machine, robots, software, networking and basic facility or infrastructure around. You must consider total cost and life cycle cost”

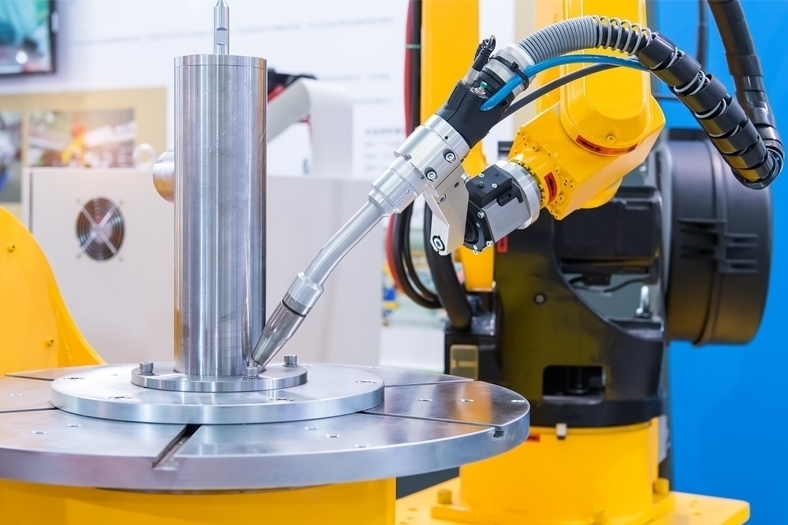

In modern edge of digital factory; lot of robotic systems are deployed in day to day production. There are several advantages of these systems over conventional production systems. Precise, repetitive manual tasks are done by robots better way as they do not think; get tired or injured. Due to this you get better productivity and quality due to consistency. When we choose a human being we do a lot to find match for job. It means we defined the job and look for human profile that it can do better. We create workplace environment and team around him. Same is needed when you buy a robot. Just like their human counterparts, robots must be well-matched to their job requirements.

When you buy robotic system you are not buying a product as a robot but you are buying a system or function which consist of machine, robots, software, networking and basic facility or infrastructure around. You must consider total cost and life cycle cost. It means do not only look at acquisition cost but also look at operation cost, improvement cost; modification cost (like increase rate of production or change in model) and maintenance cost. Following are some golden rules which might help in buying decision:

Production ratesWhen looking at production rates, it is important to differentiate between average rates and instantaneous (peak) rates as the robot needs to be designed for both. Where there are large surges in production followed by a lull, it is possible to average out the rate with a buffer.

System controlThe cost of an automated solution can vary greatly with the level of control. The robot teach pendant is typically able to keep costs down but this requires well trained operators. Pushbuttons to start and stop the system from a workstation simplify control but a better solution may include interfacing to a SCADA system with remote monitoring at the production office.

Find the right supplierWhen looking to invest in a robotic system, consider the supplier’s area of expertise and whether he has completed similar projects in the past. Also consider a supplier’s location and its preferred brand.

Essential functionsA manual process often includes steps that are not required for an automated process, but don’t overlook the simple yet important human elements. Some parts in your process are not a core function but do need to be managed. For example, do your operators check for label as you pack them you may need camera system when you use robotic system.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.