Creating digital factories

By Staff Report December 2, 2024 2:34 pm IST

Robotics and seamless automation have given rise to digital factories, which can enhance overall productivity and efficiency. Marc Segura, President of ABB Robotics Division, shares his insights on the Indian robotics market and what ABB has in store for us.

How is the robotics market progressing in India, and what are the key drivers and industries contributing to the growing demand for robots in the country?

India’s robotics market is rapidly growing, setting a new record with 8,510 industrial robot installations in 2023 —a 59% increase from 2022 (5,252 units).

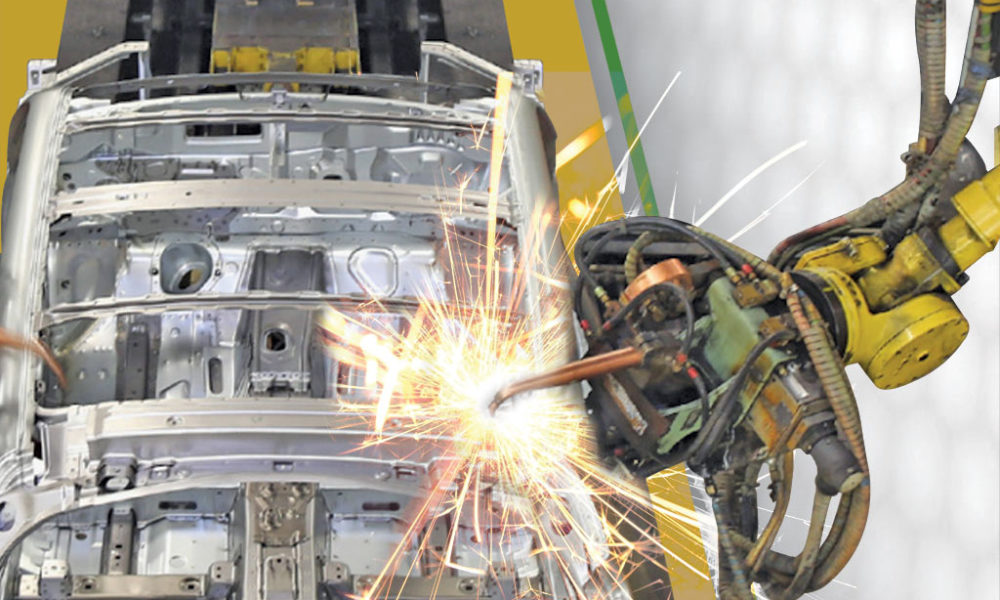

As a result of this growth, India has climbed to seventh place globally in robot installations, underlining the country’s emergence as a major automation hub. This momentum is expected to continue through 2024 and 2025. The automotive sector leads this momentum with 3,551 units installed, representing a remarkable 139% growth.

For example, Mahindra selected ABB’s PixelPaint technology in July 2024 to deliver premium paint and personalisation options for its new line of EVs. ABB India has deployed 73 robots in the country’s first end-to-end automatic car paint line, reducing the paint shop floor footprint by 30 percent and lowering energy usage and greenhouse gas emissions.

The main drivers of this growth in India and the world are global megatrends, such as uncertainty, a skilled labour shortage due to a global ageing workforce, and a need to operate more sustainably. In response, businesses demand more flexibility and efficiency to become more resilient and competitive. This is true for large, small, and medium-sized businesses, which are often embracing automation for the first time.

Specifically for India, initiatives like the Production Linked Incentive Schemes, which promote local manufacturing, and the shift of value chains, especially in the electronics sector, are catalysing automation adoption. The rise of digital factories also contributes to this growth, as they enable seamless integration of advanced technologies, enhancing overall productivity and efficiency.

What impact do you foresee the rise of robots and automation having on job opportunities in India? How can companies effectively prepare their workforce for this shift?

The growing adoption of robots and automation in India creates new opportunities across various sectors. Once limited to large industrial setups, robots are increasingly accessible and user-friendly, thanks to technological advancements, particularly AI. These innovations are lowering the entry barriers to robotics, enabling even small and medium-sized businesses to adopt automation, boost productivity and stay competitive.

While automation can replace dull, dirty, and dangerous jobs that are hard to recruit for, it simultaneously creates demand for new roles focused on designing, programming, maintaining, and managing robotic systems.

This shift highlights the importance of workforce training and education, as companies must invest in programs that equip employees with the necessary skills to collaborate with robots.

ABB Robotics has signed a memorandum of understanding with the New Age Makers’ Institute of Technology to address this and establish a School of Robotics in India. This initiative aims to bridge educational gaps in automation, improve robotics skills, and support growth in the manufacturing sector.

How is ABB Robotics leveraging AI and automation to transform industries?

Today, more than 80 percent of ABB Robotics’ offering is built on software, including AI-enabled solutions. Across ABB, we have over 250 AI-enabled solutions under development.

We’re seeing robots become more intelligent and capable of entering new and emerging sectors like logistics, healthcare, life sciences, retail, and construction. This shift to more capable automation enhances efficiency, safety, and sustainability, opening up new avenues for growth and innovation.

In construction, ABB Robotics offers bricklaying, concrete pouring, and site inspection solutions, enhancing productivity and reducing labour costs in the construction industry. Earlier this year, ABB Robotics announced a collaboration with Simpliforge Creations, an additive manufacturing solutions company, to build South Asia’s largest robotic concrete 3D printer to strengthen and advance 3D Printing technologies for the Indian construction sector.

The collaboration enables construction companies to build structures faster, more sustainably and safely. The technology can transform the construction landscape across industrial, defence, commercial and residential sectors- especially disaster-affected areas for rapid rehabilitation and infrastructure reinstatement.

Robotics is also expanding into industries that were previously less reliant on automation. AI-driven robots are making significant strides in dynamic environments like healthcare and life sciences, improving productivity and safety in the logistics and packaging sector.

In January 2024, we acquired Sevensense, a leader in AI-based navigation, to enable us to build autonomous mobile robots (AMR) with the highest speed, accuracy, and autonomy.

The Visual Simultaneous Localisation and Mapping (Visual SLAM) navigation technology of Sevensense combines AI and 3D vision using off-the-shelf cameras, allowing AMRs to make intelligent decisions based on their surroundings and navigate autonomously in dynamic environments and alongside people. Once manually guided, AMRs with Visual SLAM technology create a map that is constantly updated and shared across the fleet.

The mobile robots can carry up to a two-ton load at up to 1.5m/s and are up to 20 percent faster to commission, reducing commissioning time to days instead of weeks. Already, this technology is creating efficiencies for manufacturers like Ford and Michelin around the world.

Integrating AI and robotics brings significant benefits, including streamlined operations, reduced risks, and more sustainable practices. However, it also presents some challenges in terms of adapting existing systems and retraining, educating, and preparing staff for an age of increased AI-powered automation.

What solutions has ABB Robotics introduced to improve efficiency and address vulnerabilities in automated manufacturing?Common vulnerabilities in automated manufacturing environments include operational control, software vulnerabilities, insufficient data monitoring and human error. These issues can expose systems to operational failures and costly downtimes, often due to outdated software, insecure networks, or inadequate data monitoring.

To address these common vulnerabilities, we recently launched OptiFactTM, ABB’s new modular software platform for extracting and building business value by collecting, managing, and analysing data, and OmniCoreTM, ABB’s new, next-generation robotics control platform.

Launched in September 2023, OptiFact enables manufacturers to have greater visibility over the production data to unlock its full potential and create efficiencies that save time, energy and costs. The platform collects, manages, and analyses data from hundreds of factory devices centrally, saving up to 25 percent of the time in data collection and analysis. It also complements ABB Robotics’ existing digital solution suite and helps factory operators increase production uptime by up to 20 percent.

This can help businesses of all sizes imagine new digitally enabled processes, realise them on the factory floor, and elevate operations by simplifying production to increase productivity and flexibility. OptiFact helps factory operators determine the root cause of production errors and use ABB’s RobotStudio Cloud to adjust the program and develop an improved robotic solution.

With OmniCore, we are offering a big step forward in robot control. We are transforming efficiency, productivity, and sustainability for businesses of all sizes with a modular, scalable solution on one future-proof software platform.

Launched in June 2024, OmniCore allows the entire ABB Robotics portfolio of hardware and software to be used in any combination under a single control platform.

Streamlining operations offers greater control and increases business productivity and flexibility through faster, more precise, and more autonomous automation.

How can your robotic solution assist manufacturers to improve their quality and supply chain optimisation?

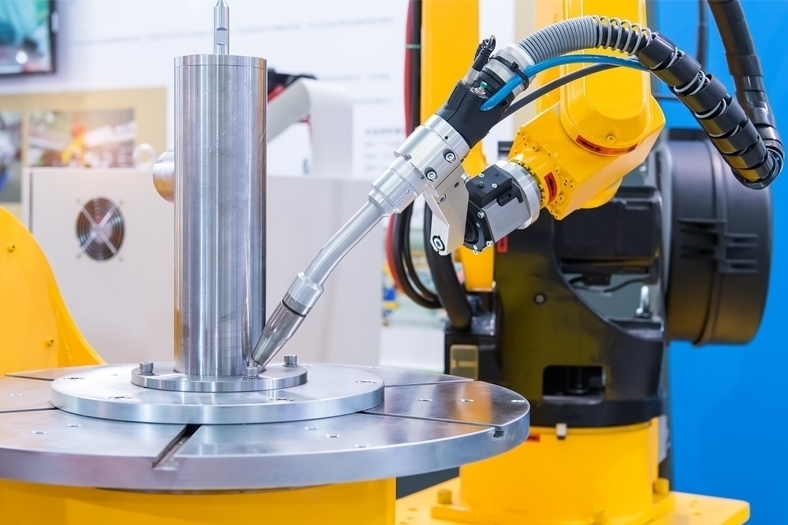

ABB Robotics helps manufacturers improve quality by automating key processes such as assembly, testing, packaging, and painting. This improves efficiency and optimises supply chains.

In sectors like healthcare and life sciences, our robots ensure precise and consistent handling of components, leading to higher productivity and fewer defects. One example was GE Healthcare, which implemented ABB’s Single-Arm YuMi collaborative robot (cobot) to automate the precise and challenging task of applying glue beads on an advanced sensor battery component in their prototype assembly line. The cobot significantly improved production speed and repeatability, allowing skilled workers to focus on other tasks and reducing the need for complex safety measures.

We are also helping to improve quality and optimise the supply chain at Mahindra through our innovative PixelPaint technology. This inkjet-like painting process delivers precise, high-quality finishes while reducing waste, improving both efficiency and sustainability and reducing time spent on each vehicle and the reliance on the supply of materials. With serial production set for 2025, PixelPaint is set to transform the automotive industry, offering improved quality control and faster turnaround times for personalised vehicles.

Can you explain the key sensors and technologies robotic solutions use for navigation and obstacle detection?

The navigation technology within ABB’s Visual Simultaneous Localisation and Mapping (Visual SLAM) enabled AMRs to combine AI and 3D vision using off-the-shelf cameras. These cameras act as the eyes and brains of the robots, allowing AMRs to make intelligent decisions based on their surroundings and navigate autonomously in dynamic environments and alongside people while combining and sharing that information with other AMRs in that setting.

Once manually guided, mobile robots with Visual SLAM technology create a map that is used to operate independently, reducing commissioning time from weeks to days and enabling the AMRs to navigate in highly complex, dynamic environments. Maps are constantly updated and shared across the fleet, offering instant scalability without interrupting operations and greater flexibility than other navigation technologies.

This paves the way for a shift from linear production lines to dynamic networks, where intelligent AMRs autonomously navigate to production cells, tracking stock inventory as they go and sharing this information with other robots while collaborating safely with humans.

ABB is the leader in next-generation AMRs, offering Visual SLAM in Autonomous Mobile Robots. Our value-creating software manages our integrated portfolio of robots and machine automation solutions.

What role does machine learning play in your robotic solutions, and how does it enhance functionality?

AI and machine learning can improve robot functionality, helping them to manage variability and unpredictability in dynamic manufacturing environments by allowing them to adjust their actions based on changing conditions. This is especially valuable for predictive maintenance, where machine learning can forecast potential failures before they occur, reducing downtime and improving operational efficiency.

Our machine learning algorithms analyse data across multiple robots performing similar tasks, leading to continuous process optimisation. This enables robots to learn from experience and improve their performance over time, making them more efficient and effective.

This is particularly beneficial in environments with high product variability or where mobile robots distinguish between objects and people, ensuring faster and more accurate decision-making in complex scenarios. An example is our AI-powered Visual SLAM AMRs working in a dynamic and ever-changing environment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.