The flexibility of VpCI Film for rust prevention in unconventional packaging

By OEM Update Editorial February 14, 2024 3:21 pm IST

The diverse applications of VpCI® Film in rust prevention and unconventional packaging brings their versatility through real-world examples of protecting large or unwieldy metal goods effectively.

VpCI®-126 Film and Bags present a convenient means of packaging and safeguarding diverse metal components. By placing small gears or bolts into a VpCI®-126 Top-Seal Bag and securely sealing it, effective rust prevention for up to two years is achieved. However, challenges arise when dealing with metal components surpassing human height or exceeding the embrace of three individuals. Fortunately, Cortec® VpCI® Film provides the requisite flexibility for users to devise tailored packaging solutions for oversized metal items.

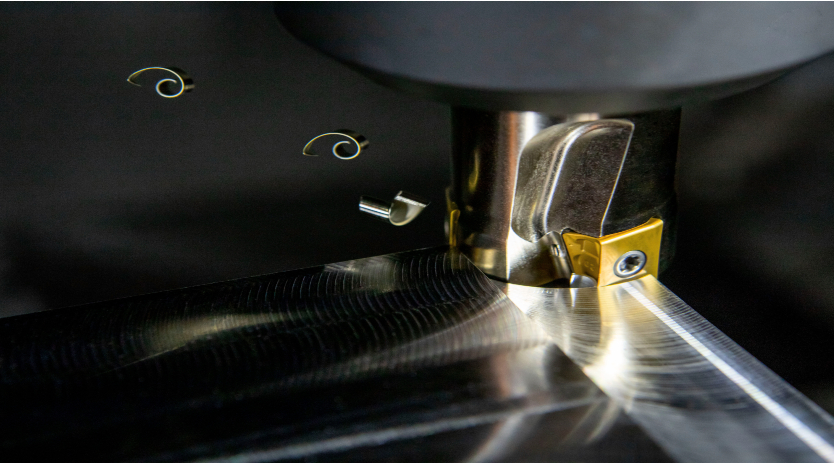

Rust Prevention with VpCI® Film

VpCI® Film is a rust preventative option for manufacturers and third-party packagers. Instead of requiring the application of greasy rust preventatives that eventually need to be cleaned off, VpCI® Film offers clean, dry corrosion protection—not only by means of a physical barrier, but also with corrosion inhibitors that work in both the contact and vapor-phase. This means the film protects metal surfaces inside the package that are directly touching the film as well as surfaces that are not.

Finding the Right Packaging for Large Items

At Cortec® Corporation, VpCI® Films come in widths up to 30 feet (9.1 m), allowing users to package extra large objects. When this is not wide enough, users can seam together sections of VpCI®-126 HP UV Shrink Film and MilCorr® VpCI® Shrink Film, two heavy duty versions of VpCI® Film, to shrink wrap extremely large or bulky items that will be exposed to outdoor conditions. For an even better fit with less fuss on the application side, users can order customized bags that will easily slip over specific sizes of equipment, requiring only a quick final shrink wrap to finish the packaging job.

Unusual Packaging Examples

Past examples show that many creative VpCI® Film packaging solutions exist for large or unwieldy metal goods.- Packaging a Giant Ring

At one time, a giant metal ring 3.5 yards (3.168 m) tall and 6 yards (5.5 m) in diameter needed to be protected for the trip to its final destination at a nuclear facility. A third-party packager used strips of VpCI®-126 Film 3.3 yards (3 m) wide to wrap the shiny new ferrule, providing protective peace of mind for the journey.

- Packaging Wind Turbine Components

Several years ago, a manufacturer of wind energy components started using VpCI®-126 HP UV Shrink Film and MilCorr® VpCI® Shrink Film to wrap new wind turbine shafts, rings, and hubs. In addition to a protective coating on some of the most sensitive parts, the components needed this heavy-duty VpCI® Film for two to five years of storage, possibly outdoors.

- Packaging Massive Power Cable Drums

In 2022, PRESSERV used MilCorr® VpCI® Shrink Film to package giant power cable drums stored outdoors as emergency backups for offshore platforms. The drums were so large that MilCorr® was seamed together to cover the entire bulk. These shrink-wrapped units were also equipped with access doors for later inspection.

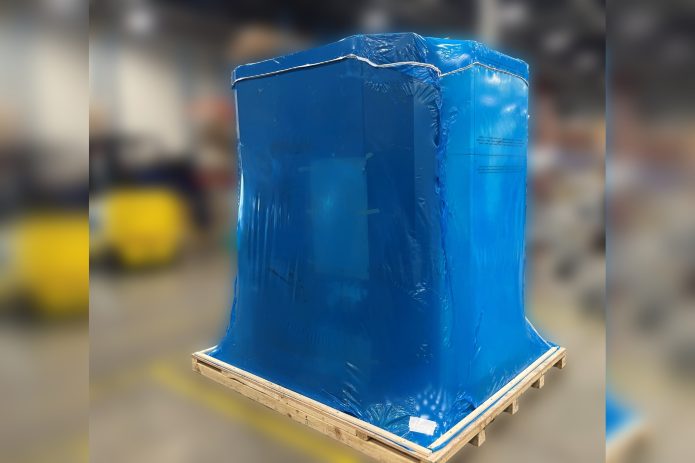

- Packaging 3D Printers

Last year, a manufacturer of 3D printers used customized bags made of VpCI®-126 HP UV Shrink Film to cut down on wood crating. The specialty bags were easy to fit over the printers, shrink wrap, and finish preparing for shipment in about 15 minutes while significantly reducing wood packaging costs.

When faced with an unconventional packaging requirement necessitating corrosion protection, VpCI® Film offers the essential flexibility to accommodate challenging sizes and storage conditions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.