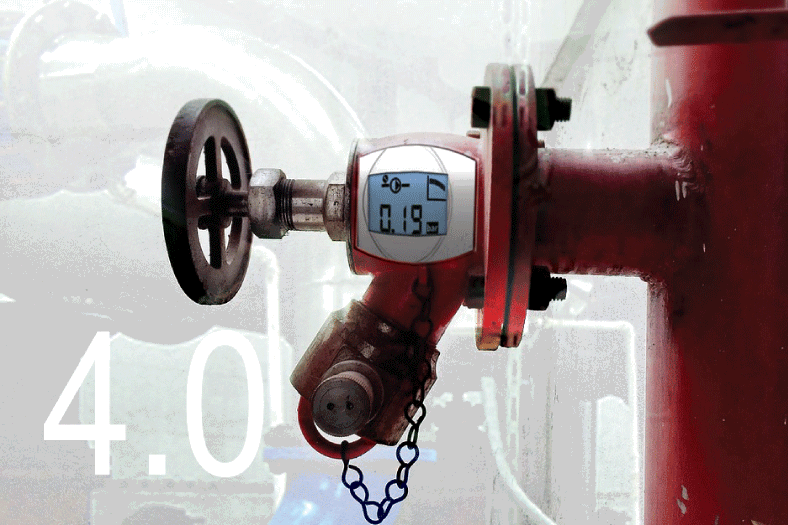

Refining pumps through Industry 4.0

By OEM Update Editorial December 10, 2018 5:39 pm IST

Evaluating pump performance is different for different applications and energy saving and optimisation is achieved in the process as a by-product. Industry applications have different demands for optimising performance of processes which generally include maintaining a particular process parameter constant, such as, flow, temperature, pressure, differential pressure etc.

Girish Laxmeshwar, Head of Business Development (Industry), Grundfos India says, “Now, maintaining these process parameters demands better control mechanism by use of intelligent pumps packaged with relevant sensors, drives and controllers which is what we at in Grundfos have been promoting under the banner of ‘iSolutions’ and ‘Intelligent Connectivity’.” Girish has also shares the examples in the following:

In HVAC applications, providing precise amount of chilled water flow across AHU coils evaluates the pump performance, which is achieved by fixing sensors in appropriate locations in the loop and then controlling the speed of pumps according to the sensor signal. In this process, the company automatically achieve energy savings as pumping is regulated according to the load demand.

Cooling of reactors in pharma industries optimally require control over exothermic reactions to get precise product quality out of reactors. This calls for regulation of pump speeds either based on temperature or by pressure. The pump performance is evaluated based on the inlet temperature it maintains at the inlet of the reactor/s. Here, energy savings is a by-product.

Uncontrolled fluid in motion

“We perceive ‘uncontrolled fluid in motion’ as constant movement of fluid irrespective of demand leading to pressure surges in pipelines and thus causing leakages. This situation results in wastage of water as well as electricity apart from causing mechanical damages to piping equipment and the pipe itself. Further, uncontrolled fluid under high pressure can harm users and operators as well,” confirms Girish.

Grundfos has a long-term ambition of providing solutions in the area of digitalisation under the Industry 4.0 platform where these intelligent solutions with intelligent connectivity will help customer in condition monitoring of pumps, predicting issues, planning spares inventory, auto correcting in some cases, etc.

The IoT platforms such as cloud computing will play a vital role here in making systems clever and follow trends by throwing necessary data into cloud to build necessary algorithms. These systems will also throw some sensible data to users for some strategic and timely decision as well. These offerings are likely to operate processes in industries with very less or almost no human intervention.

Grundfos has initiated necessary developmental work in this direction and is likely to come up with solutions in the near future depending upon the trends.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.