The new S100: the perfect machine for the entry-level segment

By OEM Update Editorial March 2, 2023 1:57 pm IST

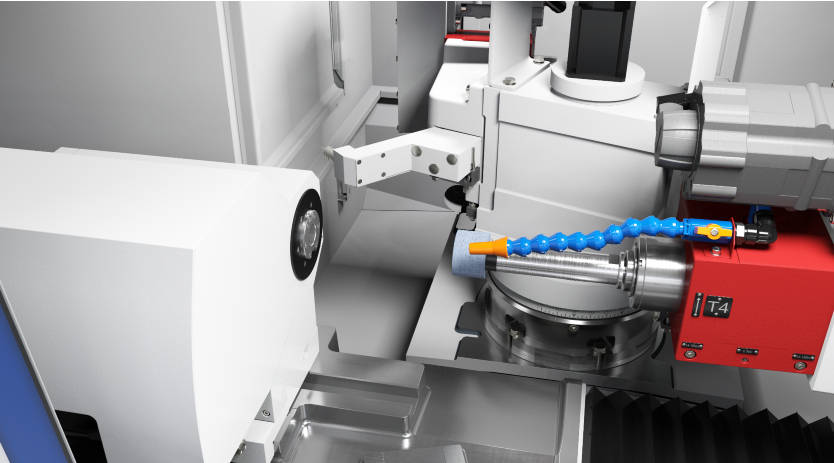

High-precision, flexible and reliable: With the new S100, STUDER presents the ideal universal internal cylindrical grinding machine for the entry-level segment. Its excellent price-performance ratio makes it the perfect machine for a wide range of internal grinding applications.

“The S100 internal grinding entry-level machine perfectly complements our comprehensive internal grinding portfolio”, explains CSO Sandro Bottazzo, when presenting the S100 at the BI-MU Exhibition for Machine Tools in Milan.

Like all STUDER cylindrical grinding machines, the S100 also has a machine bed made of Granitan®. Its outstanding dampening, and thermal characteristics ensure consistently good grinding results and the renowned STUDER precision. During the development, special attention was given to a simple and efficient design of the components, making operation and maintenance easier for the operator. However, the equipment of the S100 also makes it suitable for grinding a universal spectrum of parts comprising of geometrically defined basic forms and contours, which can be generated with interpolating axes.

Flexible equipment ensures a diversity of parts

The machine can be equipped with up to two internal grinding spindles or one internal and one external spindle. In addition to a fixed wheel head, it can be equipped manually with a 2.5 degree Hirth and, in its optimum configuration, with an automatic wheel head with 1 degree Hirth. A synchronous motor drives the grease-lubricated internal and external belt spindles. The machine is operated by the Fanuc 0i-TF PLUS controller, together with the proven STUDER operating system.

A further advantage of the S100 is the automation option. On request, it can be equipped with a loading interface and an automatic sliding door, enabling automatic operation and the production of large series.

Typical workpieces for production on the S100 include collets for toolmaking, bearing rings, ball bearings and cylinders, as well as hydraulic control valves in small series. External and internal machining of flange parts or grinding of threads or non-circular forms is also possible.

The competent and reliable STUDER Customer Care is naturally also on hand to provide advice and technical support for the S100. A total of more than 200 specialists worldwide ensure that the machine operates reliably and efficiently throughout its entire lifetime and fully satisfies all requirements. Customers can rely on the over 110-year grinding tradition of the Swiss company, founded back in 1912.

Technical data of the S100 at a glance

- workpiece length: 550 mm (21.65 inches)

- swing diameter: 425 mm (16.73 inches)

- internal grinding diameter: 300 mm (11.8 inches)

- diameter of internal grinding wheel:63 mm (2.48 inches)

- internal grinding spindle speeds:20.000/40.000/60.000 rpm

- diameter of external grinding wheel: 400 x 40 x 127 mm (15.74 x 1.57 x 5.00 inches) F1N

- Workhead: Chuck workhead ISO50/110 or chuck workhead MT4/70

- Machine dimensions W × D × H: approx. 3090 × 2090 × 1990 mm (121.65 × 82.28 × 78.34 inches)

- Machine weight: approx. 4500 kg (9,920 lbs.)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.