Cost-effective light gears a new era in low cost automation

By OEM Update Editorial December 7, 2020 6:03 pm IST

Tribo-polymers are used wherever the goal is an improvement of technical performance and a simultaneous reduction of costs. The advantages of tribo-polymers are especially apparent in the case of gearboxes: due to the use of iglidur high-performance polymers, strain wave gears from igus require no additional lubrication, in contrast to metal types of gear. Friction and wear are improved if lubrication-free tribo-polymers are used. At the same time, the use of plastics enables an extremely compact design and cost-effective manufacture. As a result of active research and further development of the strain wave gear, operating smoothness, backlash and service life have been optimised further by means of improvements in the technical design and in the selection of materials. This especially applies to the latest generation.

In order to generate accurate movement along the 5th robot axis, the motion plastics specialist igus has developed new types of strain wave gears based on its tribo-polymer technology. Due to the use of lubrication-free high-performance polymers, they are not only extremely compact and light but also require very little maintenance and have an especially long service life. The latest generation supplements the gearbox series from igus and is part of the continually growing range of products for Low Cost Automation.

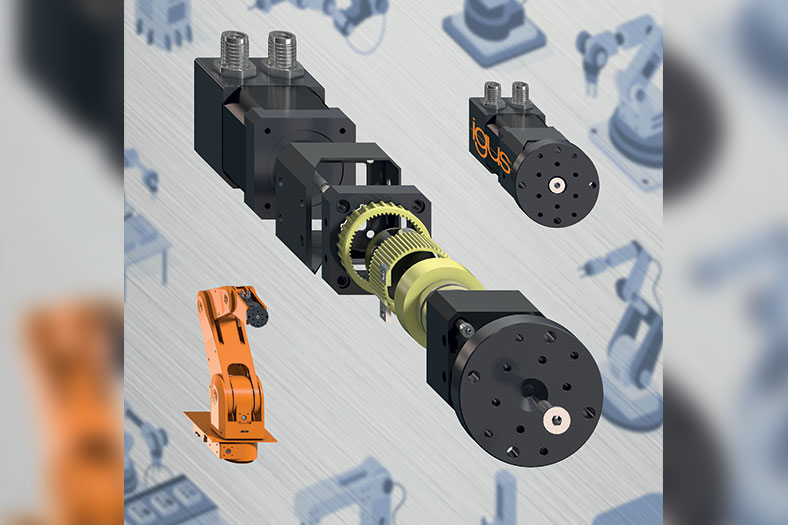

Strain wave gear made of lubrication-free tribo-polymers

The main components of the gearbox include a wave generator and a flexible ring with outer drive teeth, as well as an outer ring, fixed in place in the housing and a rotary power take-off element with inner drive teeth. The necessary flexibility and high degree of wear resistance are achieved through the use of lubrication-free high-performance igus polymers. The wave generator has an elliptical shape, therefore the surrounding flexible ring also assumes this shape. The drive teeth of the flexible ring engage at two places in the inner drive teeth of the outer ring and power take-off element. As the outer ring has two teeth more than the other components, the flexible ring is only moved two teeth further per rotation when the wave generator is rotated. Along the last axis of an articulated arm, linear robot or delta robot, the strain wave gear can be used before different gripper systems. Here, it performs the task of gripping objects that are not rotationally symmetrical and positioning them exactly. The current version is based on the installation size Nema 17 for direct connection to a stepper motor and can easily be adapted to other types of motor. The load bearing capacity of the strain wave gear has been determined in the test laboratory. With a transmission ratio of 28:1, the gearbox has a service life of 1 million cycles under a load of 1.5Nm and at a speed of 6rpm. As a next step, there are plans to develop a size Nema 23 gearbox.

Cost-effective automation solutions now possible

RBTX.com, which makes it easy to put together additional components such as gripper, control system or pneumatic components in order to create a full robotics solution. The platform brings users and suppliers of low-cost robotics components together quickly and easily. Interested parties can put together a low-cost robotics solution that matches their requirements and their budget exactly.Visit us on www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.