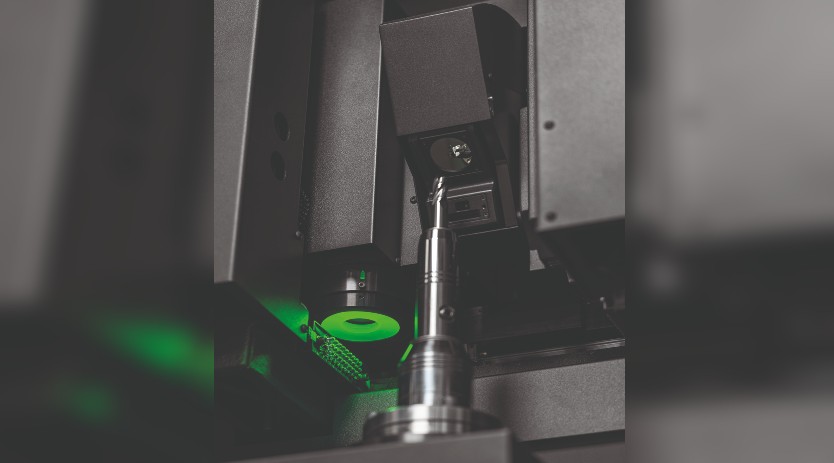

WALTER has introduced a new 3D sensor option for its HELICHECK PRO and PLUS measuring machines.

By OEM Update Editorial June 15, 2022 4:46 pm IST

For the measuring machines HELICHECK PRO, HELICHECK PLUS and their LONG versions, WALTER now offers as an option a 3D sensor for fully automatic measurement and digitisation of tools and work pieces.

When the cutting edge geometry, pitch and spiral pitch of cutting tools vary from cutting edge to cutting edge, we are talking about high-performance tools. These not only request high demands on production, but also on measurement. In view of the many varying parameters, the much faster 3D laser measurement is recommended, for example with a WALTER HELICHECK 3D. For the complete measurement, however, a more precise, conventional measuring machine was then additionally required for some measurement criteria. Until now, two measuring machines were necessary for demanding tools, such as those commonly used in the automotive, aero space or medical sectors. With the new optional 3D laser measurement, this is no longer the case.

TWO MACHINES ON THE FOOTPRINT OF ONE

3D laser measurement is now available as an option for the HELICHECK PRO and HELICHECK PLUS measuring machines. “This means that customers have two measuring machines in the space of one,” explains Siegfried Hegele, Applications Product Manager. First, the 3D sensor visualises the workpiece as a point cloud. Measurements can then be carried out using this image. Deviations in the tool can be detected by superimposing the image over the 3D design drawings. “Customers with multiple production sites can compare scans from different machines to see at which operations manufacturing differences occur,” says Hegele.NEW GENERATION OF 3D SCANNERS

The optional laser sensor is the latest generation of scanning technology. The new 3D sensor has a four times higher resolution and the measuring machine with an integrated high-end PC can process four times as much data in the same time. The swivel angle of the scan head has also been extended to -55° making a complete scan of indexable inserts possible.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.