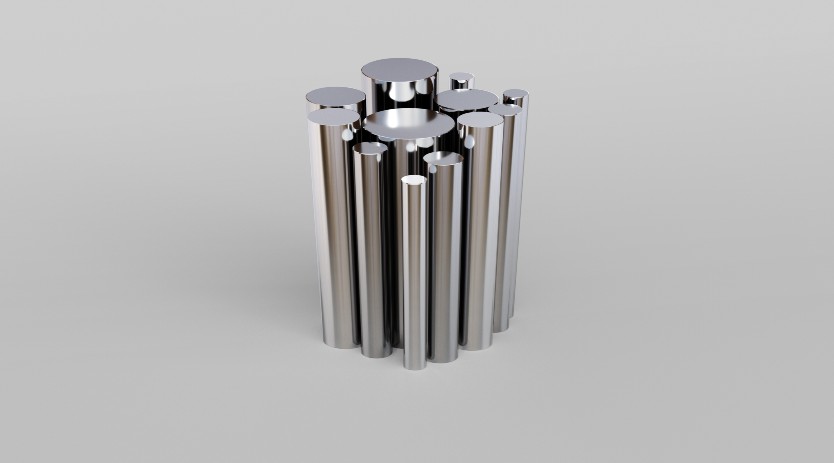

Sandvik adds Sanicro® 625 bar to family of high-performing nickel alloys for sustainable business

By OEM Update Editorial April 21, 2022 7:37 pm IST

625 is among the toughest of nickel-based alloys and really sets the gold standard for safety, reliability and performance.

In another first, Sandvik is adding super alloy Sanicro® 625 bar to its growing family of high-performing nickel-alloys. The bar will be used to machine advanced components that are exposed to acids, alkalis, seawater and other wet corrosive conditions in both cryogenic environments and temperatures up to 593°C (1100°F).

“This is great news for customers who are looking for a reliable supply of high-quality 625 bar stock,” says Henrik Zettergren, Global Product Manager. “625 is among the toughest of nickel-based alloys and really sets the gold standard for safety, reliability and performance. When you’ve got a flange, valve or fitting that simply cannot fail, it ensures high strength, extraordinary corrosion resistance, good fabricability and excellent welding properties.”

The decision to manufacture Sanicro® 625 bar and build up local stocks with trusted distributors and at its own mills in the US, Europe and Asia was largely prompted by customers experiencing sourcing challenges during the pandemic, says Zettergren. Local stocks were (and are) often scarce, production complicated and maintaining inventory costly. Yet the need for extreme safety and reliability is high among energy producers, refineries, chemical processors and marine companies.

Magnus Brink, a Technical Marketing Specialist, “We’re also seeing strong interest from geothermal power plants, solar farms, waste heat recovery plants and other renewable energy providers where molten salts, minerals and other deposits can create corrosion issues. Many tell us they also appreciate that Sandvik is making the shift towards more circular business models, reducing energy consumption, using 84% recycled steel and fossil-free energy. It’s becoming a decision-making criterion, even for bar, and a way to support our customers’ sustainability objectives.”

https://www.materials.sandvik/en/Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.