New Marley MH Fluid Cooler Models meet diverse range of Applications

By OEM Update Editorial June 18, 2021 2:35 pm IST

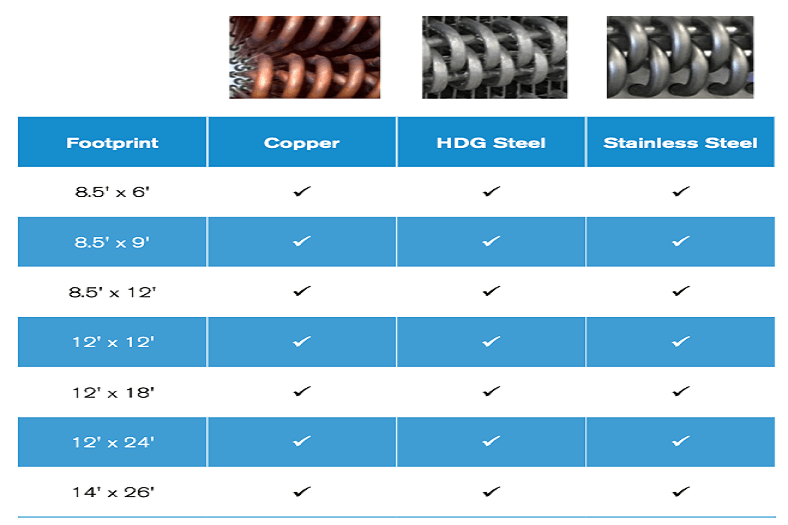

Choice of copper, HDG steel and stainless coils provide Eurovent certified performance in HVAC and industrial applications.

SPX Cooling Technologies Inc., has released details of its expanded Marley® MH Fluid Cooler line, designed to meet an even more diverse range of applications. The MH Fluid Cooler is now available with three coil materials, each delivering its own advantages.

The most recent innovation, the MH ElementTM Fluid Cooler, is equipped with copper coils. Copper offers superior corrosion resistance and improved heat transfer. Compared with traditional HDG coil fluid coolers, copper coil requires 35 percent less fluid volume, and cooler operating weight is reduced by 20 percent. Copper is also sustainable, with a high recycle value at the end of its operational life.

Other MH Fluid Coolers are available with coils of either HDG (hot dip galvanised) steel or stainless steel. HDG steel offers good thermal performance in a closed and pressurised system. Models with stainless steel coils use larger coil surface area to achieve results and are often utilised in coastal regions and applications prone to corrosion.

One of the most efficient closed-circuit cooling towers in its class, the MH Fluid Cooler is a hybrid system that combines the functionality of a cooling tower and a heat exchanger. Utilising a combination of evaporative fill media and prime surface coils, the MH Fluid Cooler offers significantly improved performance over conventional non-hybrid systems. Compared to forced-draft products with comparable footprint, its proprietary CoolBoost™ technology uses up to 75 percent less fan energy, requires up to 35 percent less process fluid, and reduces operating weight by 15 percent or more.HVAC applications include water source heat pumps, water-cooled VRF (variable refrigerant flow), geothermal heat pumps, and chillers. Industrial process cooling uses include water-cooled air compressors, injection moulding machines, induction furnaces, and another machine or jacket cooling.

Thermal capacities of all standard MH Fluid Coolers are independently certified by Eurovent and the Cooling Technology Institute (CTI) for performance with water, ethylene glycol solutions, and propylene glycol solutions. The MH Fluid Cooler is backed by SPX Cooling Technologies’ five-year mechanical warranty and energy efficiencies that exceed ASHRAE Standard 90.1 requirements.

For more information, visit: www.spx.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.