LG Chem inks cathode material supply deal with General Motors

By OEM Update Editorial February 8, 2024 3:22 pm IST

LG Chem will supply GM with over 500,000 tons of cathode materials, enough to power 5 million units of high-performance pure EVs with a 500-kilometer range on a single charge, under a long-term supply agreement that will last from 2026 to 2035.

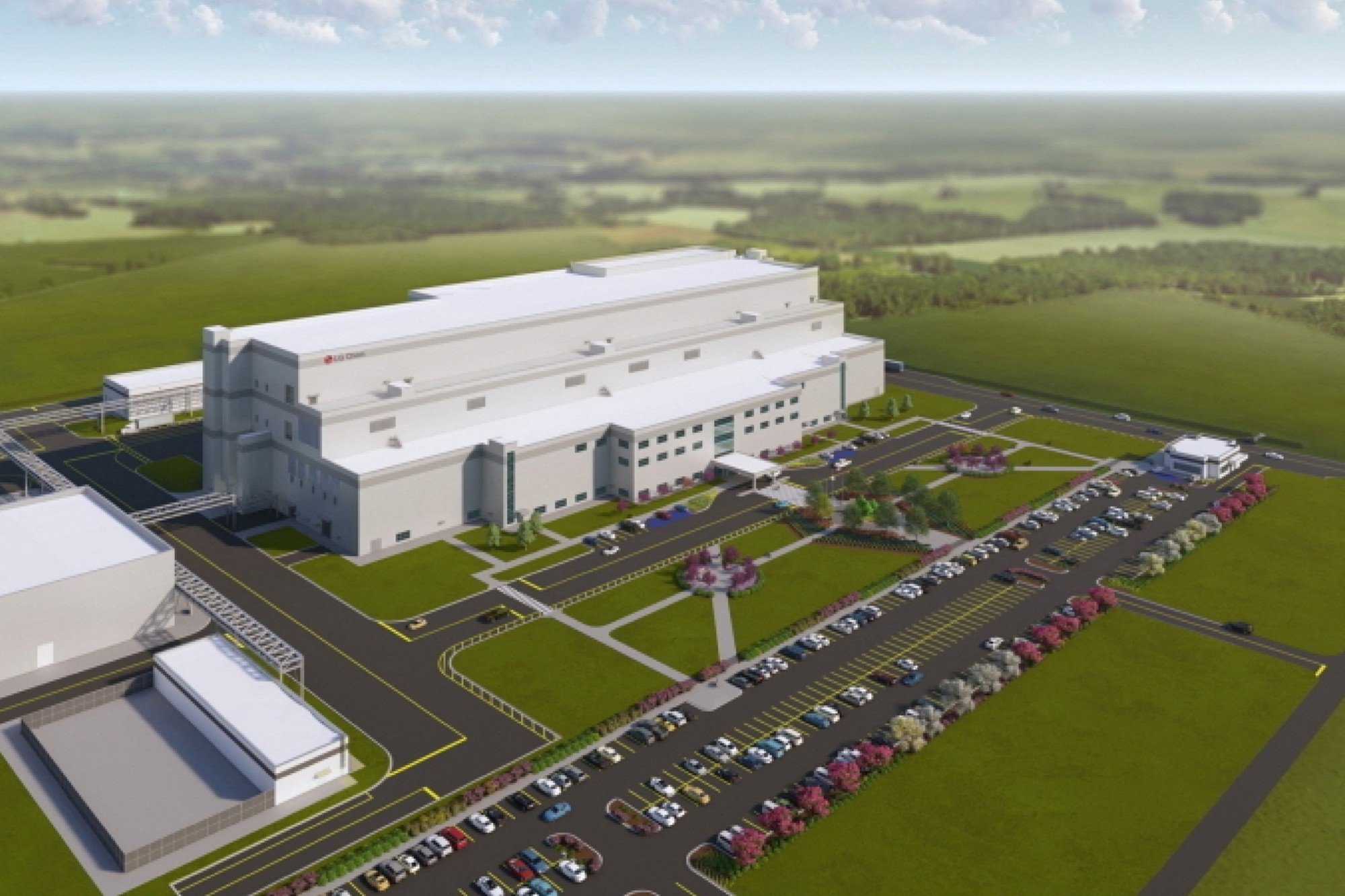

LG Chem has signed a long-term cathode material supply contract with General Motors (GM) worth KRW25 trillion. LG Chem intends to strengthen its partnership with GM in the North American market by using its cathode plant in Tennessee, USA, as a production hub for the worldwide battery materials market.

LG Chem will supply GM with over 500,000 tons of cathode materials, enough to power 5 million units of high-performance pure EVs with a range of 500 kilometers on a single charge, under a long-term supply arrangement that will run from 2026 to 2035.

Following a comprehensive agreement in July 2022 for a long-term supply of cathode materials, this supply contract strengthens the cooperation between the two companies and specifies a portion of the agreed volume.

“This contract builds on GM’s commitment to create a strong, sustainable battery EV supply chain to support our fast-growing EV production needs,” said Jeff Morrison, GM vice president, Global Purchasing and Supply Chain. “Importantly, this work with LG Chem will happen in Tennessee and strengthen the North American supply chain at a critical time for the industry.”CEO Shin Hak-cheol commented, “By strengthening our strategic cooperation with GM, we will jointly lead the North American EV market to a sustainable future. We aim to create unique customer value through world-class productivity and the expansion of our global production bases.”

LG Chem plans to supply North American-sourced cathode materials to GM starting in 2026, coinciding with the start of production at its cathode materials plant in Tennessee. The NCMA (nickel, cobalt, manganese, and aluminum) cathode materials produced in the Tennessee plant are expected to be primarily used by Ultium Cells, a joint venture between LG Energy Solution and GM. As this supply agreement is a direct contract with GM, LG Chem’s cathode materials may also be used by GM in other EV projects. LG Chem intends to utilize its local supply chain to ensure that customers, including GM, can meet the EV subsidy criteria set by the U.S. Inflation Reduction Act (IRA).

With a 60,000-ton yearly production capacity, LG Chem started building the largest cathode facility in America on December 20, 2023, in Tennessee. Using the Tennessee site as a hub for client relations, LG Chem intends to manufacture tailored cathode materials that are optimized for North American electric vehicles from the outset of development. By achieving the highest-level yearly production capacity of 10,000 tons per line in the globe through the advancement of calcination process engineering technology, LG Chem will also increase the manufacturing competitiveness of the Tennessee plant.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.