LANXESS increasingly making use of the circular economy for plastics

By OEM Update Editorial July 10, 2020 4:56 pm IST

Specialty chemicals company LANXESS is increasingly making use of recycled raw materials in the production of its thermoplastic compounds and composites. “We want to help make the switch from a throw-away society to a circular economy. Our goal is to make more and more of our plastic products sustainable so that we can make our growth less dependent on the consumption of finite resources, improve our carbon footprint and protect the environment,” explains Dr. Guenter Margraf, global product manager at the company’s High Performance Materials (HPM) business unit.

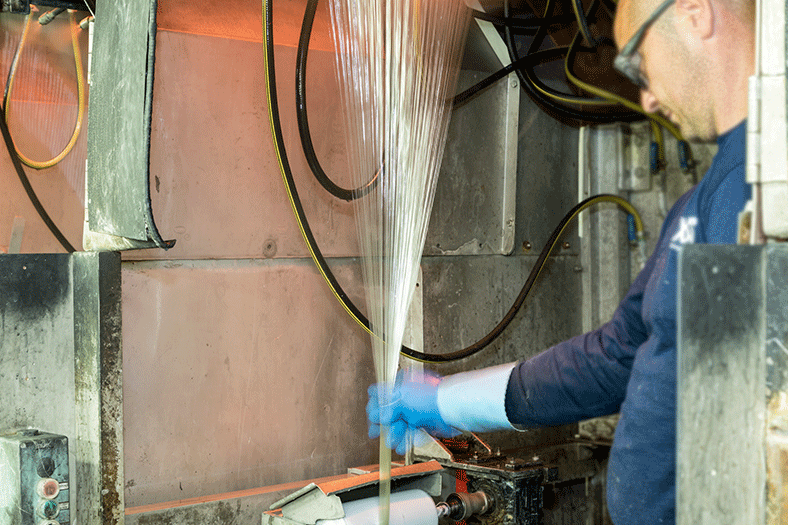

Durethan ECOBKV30H2.0, ECOBKV35H2.0 and ECOBKV60XF are the most recent examples of products made in line with this strategy. Recycled fibers manufactured from waste glass make up 30%, 35% and 60% by weight respectively of these three new polyamide 6 compounds. Ecocycle, an independent inspection company, has examined the amount of recycled material in each compound and the long-term use of the glass waste stream using the mass balance method and awarded an ecoloop certificate in accordance with ISO 14021:2016. The glass comes from waste left over from glass fiber production (post-industrial recycling).

HPM’s primary target for the three new compounds is the automotive industry.Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.