How to make big data intelligible

By OEM Update Editorial April 13, 2021 6:45 pm IST

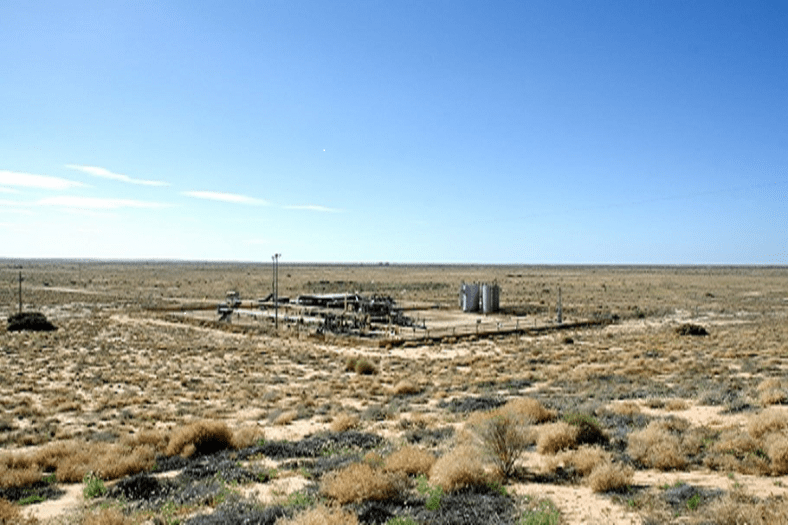

Deploying RTUs on industrial assets is an important element of capturing, interpreting and using big data from an industrial process.

The principle benefit of being able to remotely monitor an asset using an RTU is that it allows operators to regularly verify from a laptop or smart device that is operating within agreed parameters. RTUs capture big data so that operators can monitor all critical applications in a process, ranging from hours of run time, oil temperature, through to faults and load levels. They monitor the external environment, too.

The alternative is to send an engineer for routine inspection which in a remote location or expansive industrial site can be hazardous and time consuming. In some cases, it will require a second visit because they will only be able to identify faults when on site and then must source a replacement part back at base. Knowing this information beforehand can save valuable time by carrying out maintenance in a single visit.

RTUs, such as our TBox, act as both the site controller and the site communications gateway. They collect data directly, or provide a secure VPN, to PLCs used to monitor the asset. The collected data is then made available to the operators who can issue commands back to the RTU to control the asset. In parallel, the RTU relays key information to the asset owner or maintenance partner. With its ability to report alarms and historical data via email, SMS and FTP, it means nominated personnel are always being updated on its status.

www.ovarro.comCookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.