Hexagon’s new wireless laser scanner for measuring CNC machine tools

By OEM Update Editorial March 31, 2021 3:19 pm IST

The sensor can capture around 40,000 measurement points per second and the scanner will remove bottlenecks by taking an inline measurement for in-process enhancements away from CMM machines.

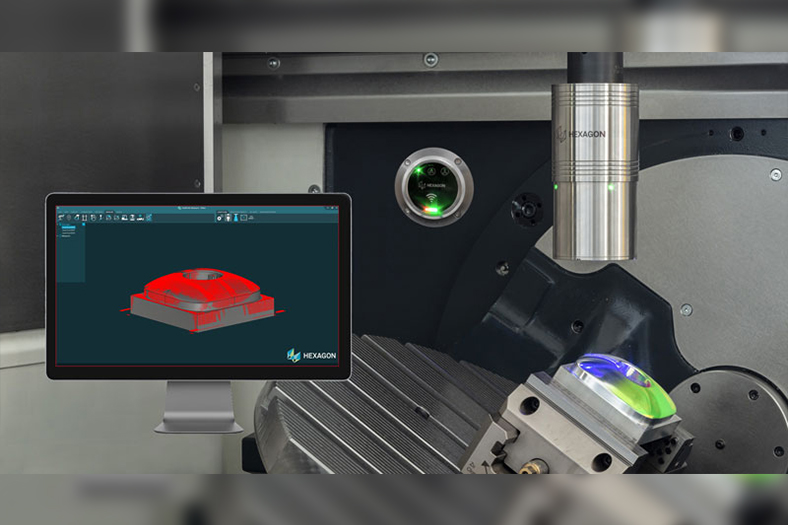

Hexagon’s Manufacturing Intelligence division has launched a multi-sensor wireless laser scanner with levels of precision, designed to work inside CNC machine tools.

The m&h LS-R-4.8 can capture around 40,000 measurement points a second compared to the status quo of taking individual points with traditional touch probes and securely transmits the data to the receiver via radio which enables operators to change the sensor automatically without manual intervention.

Measuring on the machine tool, whether for workpiece inspection, temperature, or tool control, is a valuable source of information in the machining process. With this data, workpieces can be controlled before or even in between machining. In this way, the quality of products can be assured and measurement results are used to flexibly improve production, for example through automatic part alignment. These small improvements accumulate to improve production efficiency.

The wireless scanner will remove bottlenecks by taking an inline measurement for in-process enhancements away from CMM machines. In modern production, manufacturing often must stop until the results come in. This new wireless laser scanner provides quick measurement on the machine tool and the results are quickly sent to relevant areas of the production, such as quality engineers or production managers.

Capturing 40,000 measurement points a second provides information about the complete part rather than just selected individual points. This enables users to evaluate product quality, enhance production processes by identifying problems early. It helps to align the parts for steps later in the workflow and provides an insight into the complete part quality.

Manuel Müller, product marketing manager comments said, “Wireless connectivity means these measurements are now all possible without moving the part away from the machine or installing external mobile measuring devices; both of which would be time-consuming.”

Everything runs with just one receiver and Manuel Müller explains, “We’re working with OEMs who will fit several sensors to their machines, which can simply be switched automatically for particular applications, depending on the program the user is running.”

Working principally with machine tool companies, enabling them to deliver added value to their customers, Hexagon has been providing a solution that can be used on multiple machines from different machine tool OEMs. The laser is just one of a series of Hexagon measuring devices that turn a machine tool from any supplier into a full multi-sensor device.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.