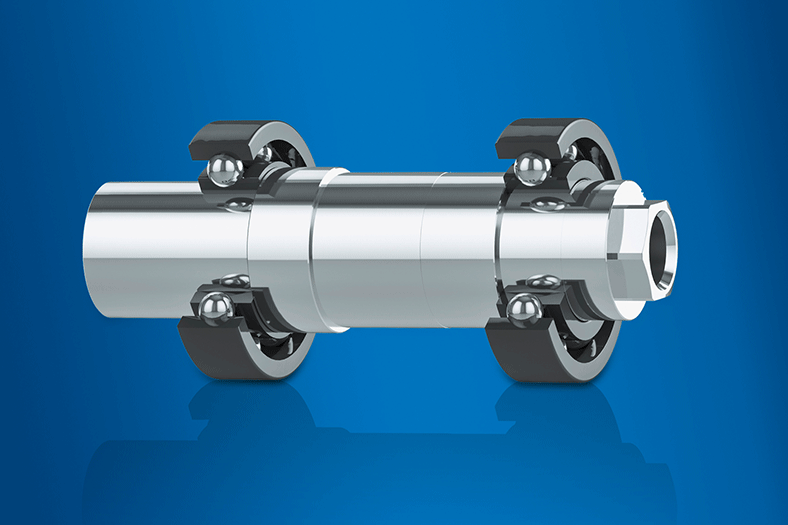

HeavyDuty rotary encoders – the high precision heavyweight champions

By OEM Update Editorial April 17, 2020 3:38 pm IST

HeavyDuty rotary encoders from Baumer Hübner are the “original”. More than half a century ago, Baumer

Hübner developed this type of particularly reliable and robust rotary encoders. Since then they have been

used in all situations where the going is tough and where failure is not an option.

What distinguishes a HeavyDuty rotary encoder exactly and what options do they offer users?

Dockside cranes that unload thousands of tons of shipped goods daily. Conveyor systems that carry

thousands of tons of mined ore from mining plants across many kilometers. Elevators that carry thousands of

people daily. Automated production lines on which automobiles in various assembly stages are transported.

Lifting bridges with a total weight of 1000s of tons that can carry several trains at once and that are lifted

many times per day to allow ships to pass. These and many other application scenarios constitute the world

of HeavyDuty rotary encoders – anytime difficult tasks must be reliably carried out under difficult conditions

and over the long term.

The term has been linked to Hübner Berlin since the 1950s, when the company established the supreme

rotary encoder class. Since that time, Hübner Berlin, which today belongs to sensor specialist Baumer, has

continuously improved its products and is still considered the expert provider of HeavyDuty rotary encoders.

But what do we mean when we talk about HeavyDuty products? After all, the term is not legally protected or

To Baumer Hübner, “HeavyDuty” is an all-encompassing performance promise. First of all, this means that

such a rotary encoder never lets its user down, even under the most difficult conditions. And secondly that

these heavyweights work as precisely as “small” rotary encoders for an extended period of time. HeavyDuty

rotary encoders from Baumer Hübner accomplish this through four characteristics:

Precision: A rotary encoder must deliver reliable signals to allow users to precisely control and regulate

1/4

drives and generators. Plant control systems utilise these signals for speed monitoring of drives or for

position feedback of machine parts. To controllers, this information is the only way to get informed and

intervene, for example, if a drive exceeds or falls below a defined speed limit. Since the machines and

systems are usually very big – dock cranes, bucket-wheel excavators, rolling mills, garbage shredders – they

could give the above-mentioned impression that precision does not matter much. That is a mistake.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.