EC.PR system now monitors energy chains in crane systems

By OEM Update Editorial January 28, 2021 1:59 pm IST

A system failure is the worst-case scenario for crane operators. Often high costs are incurred not only for repair and maintenance, but above all for downtime and non-produced goods.

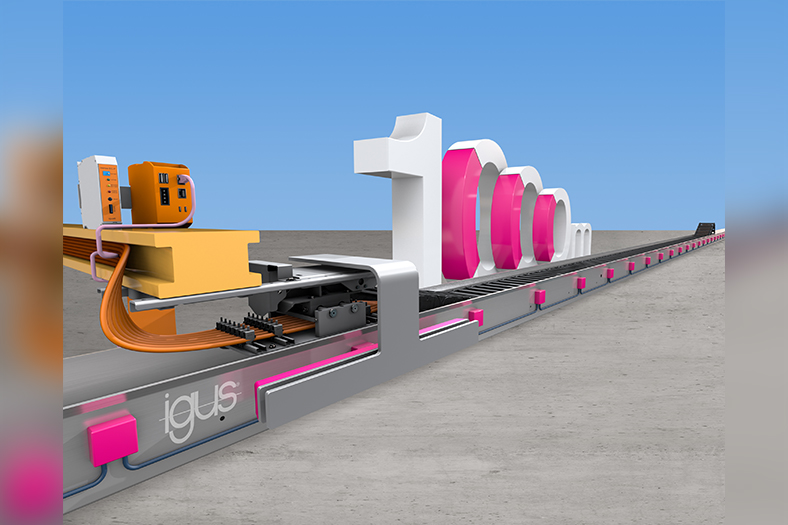

igus has developed the EC.PR system especially for long travel energy chains from 150 metres upwards, which uses sensors to determine the push/pull force of the energy chain and automatically switches off when a defined force is exceeded. This can prevent a crash of the system. If, for example, a foreign object enters the energy chain or if the trough bends, the push/pull force increases at that position. The system detects the changed value and switches off the system. By means of the new EC.PR system, the force for switching off the trolley is automatically adjusted to the position. The system receives the position information from additional modules of the Siemens PLC, an OPC-UA server, and analogue or digital position measuring systems. The EC.PR system can be easily integrated into existing control concepts and switch cabinets.

Tested under real conditions at outdoor test facilityThe EC.PR system consists of two sensors that communicate with each other. A sensor measures the push/pull force of the e-chain while, for example, a digital distance measuring system determines the exact position of the trolley or the moving end of the e-chain. For this purpose, so-called “beacons” are attached to the outside of the guide trough at a distance of 500 millimetres. Each position and thus each beacon is assigned a specific push/pull force. If the assigned maximum push/pull force of a position is exceeded, the system switches off automatically via the EC.PR. The user can remove the foreign object from the energy chain, reset the system and then put the system back into operation. The new system has already been successfully tested at the 200 metre long outdoor test rig at igus in Cologne.

For more details: www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.