ANCA joins the fight against COVID-19 – manufacturing components for life-saving ventilators

By OEM Update Editorial May 15, 2020 12:48 pm IST

Coming to the aid of a medical system crushed world-wide by the COVID-19 pandemic, ANCA has joined an important consortium to rapidly manufacture invasive ventilators within Australia. This initiative directly addresses the critical supply of mechanical ventilation equipment to support COVID-19 patients requiring ventilation to survive. Banding together with other Australian manufacturing businesses, the consortium can harness various industry capabilities to make more ventilators sooner.

Building on over 45 years of innovation, ANCA has taken its industry know-how to pivot to COVID-19 related manufacturing to support national efforts to produce more ventilators. ANCA’s dedicated project team will draw on the skills and experience of engineers and manufacturing production teams to support this venture while maintaining business-as-usual production, service and support for its global customers.

Co-founder and managing director, Pat Boland said: “ANCA is an advanced manufacturer that supplies to a wide range of industries, a key one being the medical industry. In fact, ANCA has been classified in the US as an essential industry because so many of our customers are manufacturing medical components.”

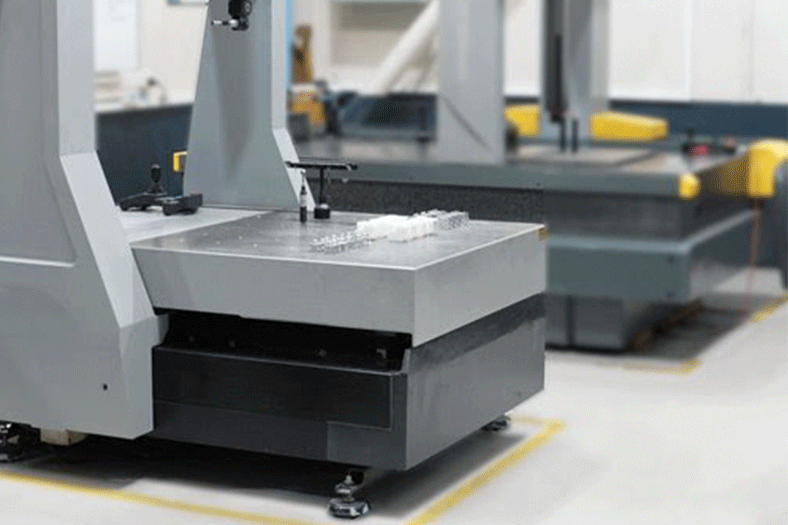

ANCA is a manufacturer of CNC machines that produce quality precision cutting tools. Their experience in advanced manufacturing means they can guarantee a micron precision, a capability which means the company could pivot and utilise its machine shop to manufacture parts for the ventilators. An Australian-based company, ANCA exports 98 percent of their product and boasts a global network to service global customers. Fully Australian and privately owned, ANCA machines have the capacity to machine components in brass, aluminium, plastic and steel and has skilled assembly capabilities.

Pat adds: “ANCA is Melbourne based, and we are very excited by the prospect of being involved with a home grown project and helping make a contribution to the manufacturing industry; making ventilator components and sub-assemblies to support urgent medical requirements.”

Around the world it is predicted that total demand for ventilators could run into the tens of thousands, with existing manufacturers unable to meet demand.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.