ABB Robotics advances in automation for construction industry

By OEM Update Editorial May 26, 2021 7:12 pm IST

Robotic automation offers huge potential to enhance productivity, efficiency and manufacturing flexibility throughout the construction industry, including automating the fabrication of modular homes and building components off-site, robotic welding and material handling on building sites and robot 3D printing of houses and customised structures.

ABB Robotics is driving automation in the construction industry with new robotic automation solutions to address key challenges, including the need for more affordable and environmentally friendly housing and to reduce the environmental impact of construction, amidst a labour and skills shortage.

9 out of 10 construction businesses predict a skills crisis by 2030, with 81 percent saying they will introduce robots in the next 10 years, while safety and the environment both are catalysts for accelerating investment in robotics.

Robotic automation offers huge potential to enhance productivity, efficiency and manufacturing flexibility throughout the construction industry, including automating the fabrication of modular homes and building components off-site, robotic welding and material handling on building sites and robot 3D printing of houses and customised structures. As well as making the industry safer and more cost-effective, robots are improving sustainability and reducing environmental impact by enhancing the quality and cutting waste.

“With so few construction businesses using automation today, there’s huge potential for us to transform the industry through robotics. Unlike building cars or assembling electronics, many techniques used in construction haven’t changed for generations, so we are developing new solutions to address key industry challenges,” said Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area. “This new customer segment will broaden our portfolio as part of a wider strategy to accelerate expansion in high-growth segments including electronics, healthcare, consumer goods, logistics and food and beverage, to meet the growing demand for automation across multiple industries.”

Robots enabling a new approach

With the industry facing increased environmental regulation and the need for more cost-effective buildings, robotic automation reduces waste by improving quality and consistency, which is significant when it’s estimated that up to a quarter of material transported to a building site leaves as waste. With automation and digital solutions, builders can also design waste out at the beginning of a project through effective building design and construction processes.“A new focus on health, safety and sustainability are catalysts for investment in robotics, while the shrinking pool of skilled labor means the construction industry needs robots to help keep pace with the challenges of urbanisation and climate change,” added Atiya. “We are putting our expertise and industry-leading portfolio of robots and digital tools at the center of the construction industry value chain with automation solutions for faster, more affordable and sustainable construction, while supporting the industry’s labor shortage, by handling large and heavy loads, accessing dangerous spaces and enabling new, safer ways of building.”

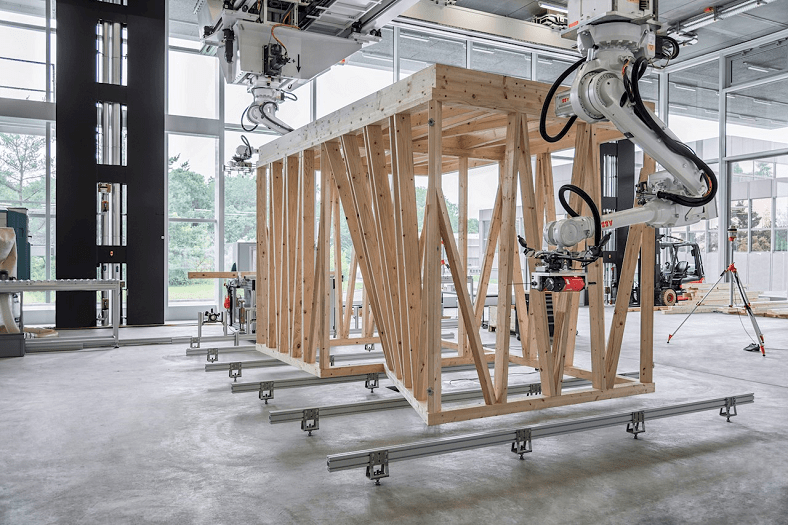

ABB is also working with several leading universities to co-develop new automated construction technologies including ETH Zurich, a leading research university in Switzerland. At ETH, ABB is supporting research in the field of robotics fabrication in architecture and construction and has helped establish the world’s first laboratory for collaborative robotic digital fabrication in architecture, hosted at the ETH’s Institute of Technology in Architecture.

For more information, visit the ABB website.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.