Yokogawa improves the CENTUM VP system for smoother industrial operations

By OEM Update Editorial April 12, 2024 2:25 pm IST

This new CENTUM VP update includes functional advancements to the UACS and CCC InsideTM for the Yokogawa CENTUM VP compressor control solution, which will increase plant operations and engineering efficiency.

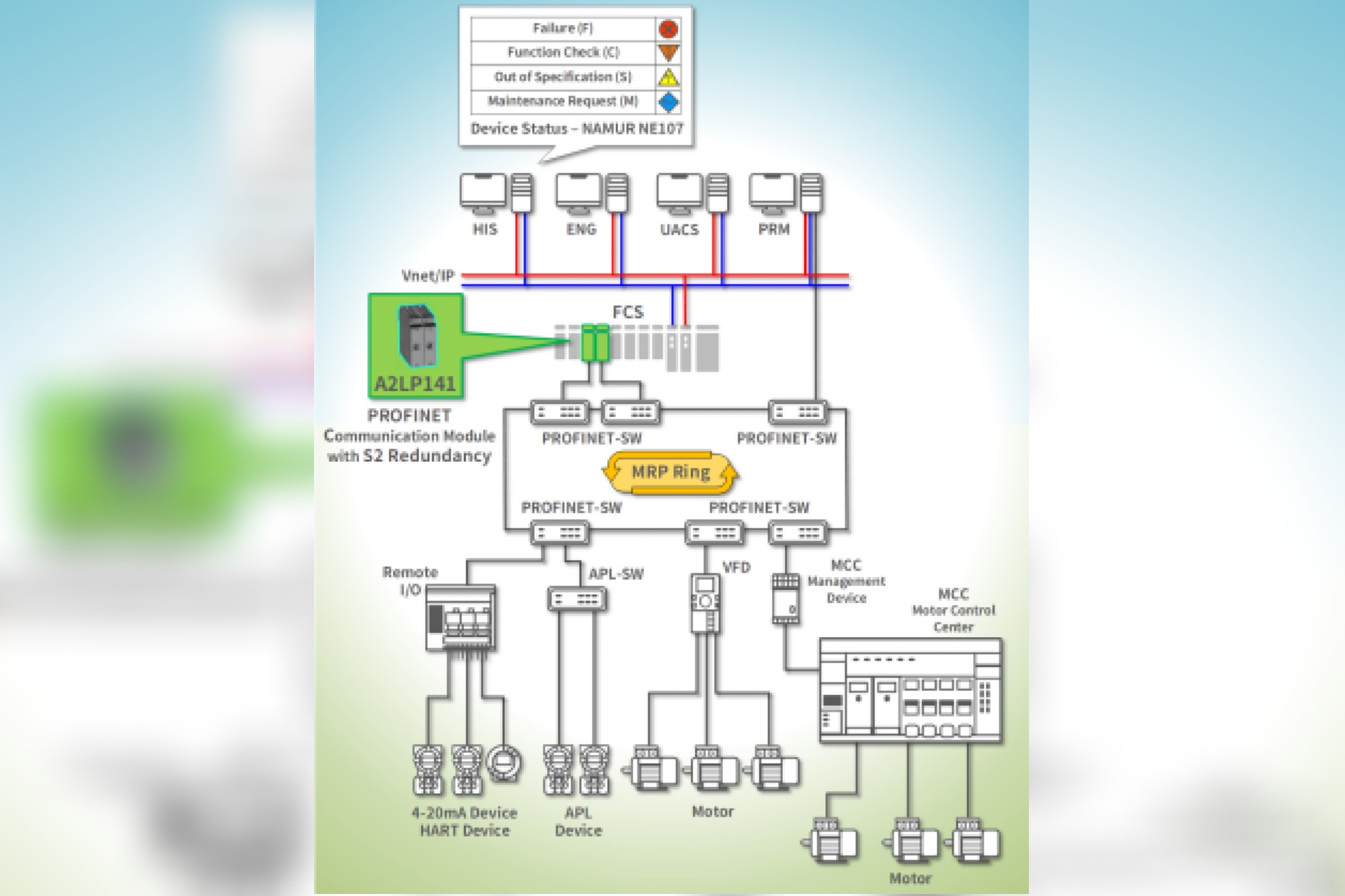

Yokogawa Electric Business with the addition of a redundancy function to a new IO card that supports communications via the PROFINET communications protocol for industrial networks, CENTUM V, VP R6.11.10 plant uptime is strengthened. Additionally, functional improvements have been made to the Unified Alarms and Conditions Server (UACS) and the CCC InsideTM for the Yokogawa CENTUM VP compressor control solution in order to save project costs and increase plant operations efficiency.

PROFINET is one of the most frequently used Ethernet-based industrial communications protocols, with excellent real-time performance. In 2019, Yokogawa created an IO board that supports PROFINET. While this enabled CENTUM VP to monitor the operation of PROFINET-compatible devices, more work was required to improve reliability and uptime. To satisfy this need, Yokogawa created a new PROFINET IO card with a redundancy feature, enabling high dependability and uptime.

This new CENTUM VP update includes functional advancements to the UACS and CCC InsideTM for the Yokogawa CENTUM VP compressor control solution, which will increase plant operations and engineering efficiency. Yokogawa Electric Business is set to release CENTUM VP R6.11.10 on May 31, 2024, an enhanced version of the OpreX™ Control and Safety System.

Product Features

A third-party agency has verified the new PROFINET IO card as meeting all PROFINET functionalities for Conformance Class*2 B (CC-B), including system redundancy, which is critical for process control. The card now includes an S2*1 redundancy capability, allowing it to be used in redundant configurations. It also allows for the use of NAMUR NE107*3 compliance self-diagnostic information from devices that support PA Profile 4.0*4, as well as remote I/O and Ethernet Advanced Physical Layer (Ethernet-APL) compatible device operation monitoring, hence broadening the breadth of control with a single control system.Improved plant operational efficiency through alarm management that supports NAMUR NA102. When a specific alert is suppressed in the UACS, the suppression status is now visible in the Human Interface Station (HIS) graphics. Enabling the deployment of alarm management in accordance with NAMUR NA102*3 can help to increase operational efficiency across a plant.

The process and compressor control systems can now be integrated and engineered utilizing a single CENTUM VP project database. This version of CENTUM VP also allows process and compressor control systems to connect to a Vnet/IP*5 control network inside the same domain. As a result, this provides for extremely seamless system integration while also lowering project and maintenance expenses.

PROFINET is a duplexing mechanism that creates an application relation (AR) between two PROFINET IO controllers and a single PROFINET IO device. It defines the range of functions available to a PROFINET device, with three incremental classes: CC-A, CC-B, and CC-C. The German process automation user organization’s NE107 and NA102 requirements include self-diagnosis functions and alert management methods. Yokogawa created a control network that is highly reliable and responsive, adhering to the IEC 61784-2 communications standard for process industries.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.