WALTER and EWAG to unveil next-gen manufacturing technologies at Open House 2025

By Staff Report April 11, 2025 6:48 pm IST

WALTER and EWAG, part of the UNITED GRINDING Group, are set to host their highly anticipated Open House 2025 at their Tübingen headquarters. This year’s event showcases cutting-edge innovations that redefine the future of precision tool machining, automation, and service solutions.

Bringing together over 200 global customers, the Open House 2025 is a live technology experience spotlighting WALTER EWAG’s latest developments. With a special focus on superhard materials, the event introduces a dynamic lineup of technologies designed to enhance productivity, reduce downtime, and address industry-wide challenges in precision manufacturing.

Innovation highlights

At the heart of this year’s showcase is Automated Tool Production (ATP), an intelligent, integrated automation solution that addresses the increasing demand for operational efficiency and skilled labour shortages. ATP’s modular RoboCell and Mobile Robot units seamlessly connect grinding, eroding, and measuring systems, enabling fully automated production environments. With retrofit capabilities, ATP offers unmatched flexibility for existing machines, ensuring cost-effective scalability and improved cycle times without altering production layouts.

Another breakthrough is the VISION LASER, WALTER’s debut laser processing solution for superhard materials such as PCD, CVD, MCD, and carbide. Built on the proven HELITRONIC VISION 400 L platform, this high-precision machine delivers breakout-free cutting edges, chip breaker processing, and superior surface quality. With no need for consumables like coolant or wire, the VISION LASER is a sustainable, cost-efficient alternative to traditional wire eroding methods.

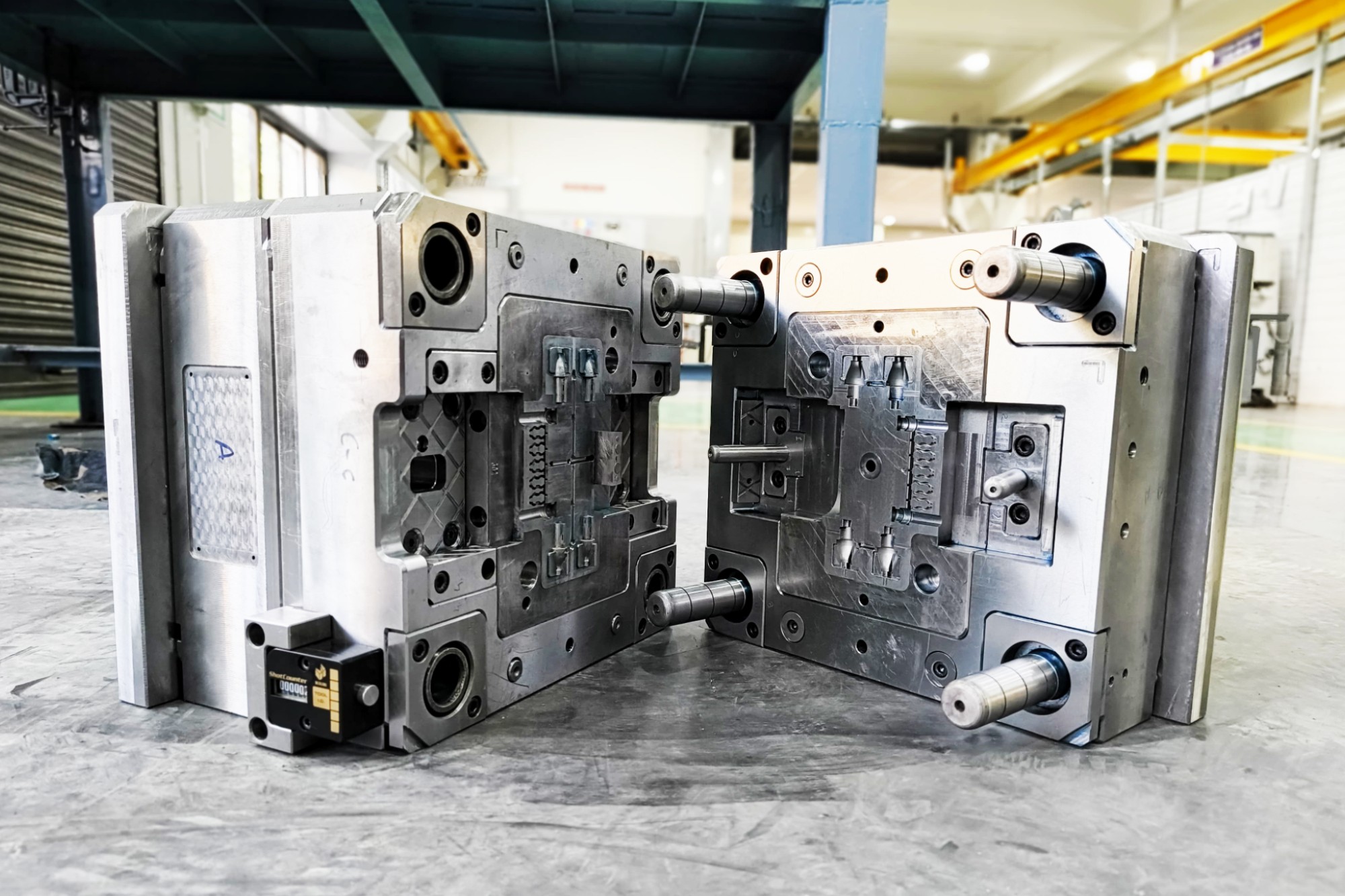

Further strengthening its innovation portfolio, WALTER will present the HELICHECK NANO, the world’s first fully automated measuring machine for nano and micro tools. Equipped with dual backlight systems, high-resolution cameras, and a microscope turret, the HELICHECK NANO supports operator-independent quality checks—meeting the needs of industries such as electronics, medical technology, and mould-making, where micro precision is critical.

Also on display will be the Fire Stop & Go, a smart safety feature embedded in HELITRONIC RAPTOR DIAMOND machines. This advanced fire prevention system minimises production downtime by intelligently analysing and responding to fire risks during eroding. This allows for the safe continuation of operations without full system shutdowns.

The event will also launch HELITRONIC RAPID, a robust, entry-level 5-axis CNC tool grinding machine for sharpening and manufacturing tools. Designed for flexibility and ease of use, it offers a cost-effective entry point into high-precision machining.

Customer-Centric Solutions

In alignment with its service-first philosophy, WALTER EWAG introduces the WE CARE maintenance program. This modular, customisable support service includes remote diagnostics, flat-rate travel costs, and predictive maintenance tools like the Digital Fingerprint. Customers can tailor packages ranging from basic condition checks to full-service coverage.

Complementing this is the Transaction Network, a manufacturer-neutral digital platform offering 24/7 access to asset data, spare parts ordering, and integrated ERP procurement processes. With features like single sign-on, real-time service updates, and intelligent ecosystem connectivity, the portal empowers customers with enhanced transparency and efficiency across the machine lifecycle.

For more information, visit www.walter-machines.com or contact marketing@walter-machines.de.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.