Tool changer procedures can now be automated

By OEM Update Editorial March 17, 2020 6:08 pm IST

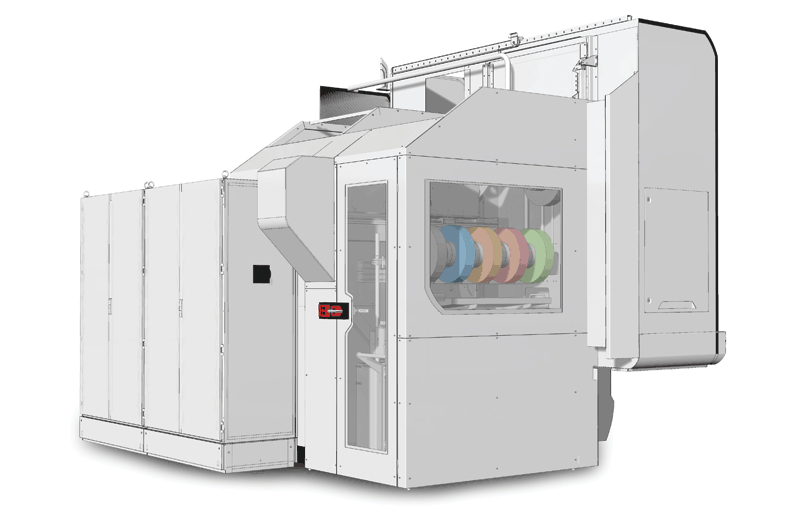

BLOHM presents for the first time a PROFIMAT XT with tool changer. The highly productive, flexible PROFIMAT XT merges four grinding technologies in one machine: reciprocate, creep feed, CD and speed stroke grinding. Thanks to the tool changer, these procedures can now be automated. In this process, the changer offers users other benefits: it can be loaded with several tools of the same type to be able to quickly and automatically replace worn grinding wheels. The tool changer also makes unsupervised processing possible, even of complex work pieces requiring grinding wheels with different profiles. Setup times are additionally cut as the unit can be loaded while the process is ongoing. The tool changer also improves general machine handling because it is easier for workers to load the changer with large grinding wheels than directly fit these in the machine themselves. Users also benefit from significantly more efficient machining. For instance, roughing or finishing grinding wheels can be prepared in the changer to thus achieve a high abrasion performance and an accurate level of detailed surface machining as part of a single process.

Benefits at a glance:

- Automated production

- More efficient machining

- Automatic operation of complex work pieces

- Option to load sister tools

- Setup while process is ongoing

- Simplified handling

- Magazine with four grinding wheels

- grinding wheel diameter: 400 mm

- grinding wheel weight: 40 kg

- grinding wheel width: 160 mm

Key tool changer data:

For more information, visit:

www.blohmjung.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.