DMG MORI begins local production in India for CMX 600 Vi

By OEM Update Editorial November 15, 2019 11:56 am IST

DMG MORI CO., Ltd. (hereinafter called DMG MORI) has started local production for their vertical machining center CMX 600 Vi for the Indian market on October 29. The production will be outsourced to Lakshmi Machine Works of India, which makes possible a shorter lead time until delivery than domestic production in Japan. The DMG MORI’s highly-reliable machine contributes to boosting productivity of customers in the remarkably growing Indian market. Mori, President of DMG MORI, and Sanjay Jayavarthanavelu, Chairman and Managing Director of LMW, extended greetings and cut the ribbon with guests.

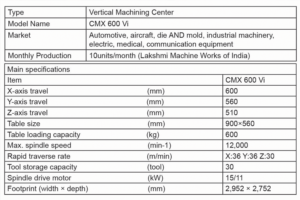

The machine CMX 600 Vi specialised for Indian customers is manufactured at the LMW’s factory with an initial production volume of 10 units a month. The production volume will be increased in stages. The features of CMX 600 Vi are described below in terms of wide work envelope, high rigidity, high-performance spindle, workability, maintainability and reliability.

1. Wide Work Envelope

The CMX 600 Vi ensures a widework envelope despite a space-saving design. With the largest Y-axis in its class of 560 mm, the machine is capable of handling round-shaped large workpieces such as gear box housings which are difficult to cut on the machines in the same class. Because of its wide work envelope, interference can be reduced even when workpieces are rotated on the rotary table during machining.

2. High Rigidity

FEM analysis was used from the basic designing phase, and simulations of varieties of operational conditions and environmental changes were made to optimise the bed thickness, lib form and unit arrangement. The fundamental rigidity supports stable cutting performance to do heavy-duty cutting.

The model is equipped with a high-reliability spindle with a max. speed of 12,000 min-1 to handle a wide range of machining. For machining that uses high-pressure coolant frequently, the labyrinth structure of the spindle was strengthened to prevent coolant from entering inside and increase spindle rigidity. As spindles are components that especially require a high level of accuracy and rigidity, the model employs the spindles manufactured in-house. Every process from production and assembly of spindle parts to the final inspection is done in the Spindle Plant, at the Iga Campus.

4. Workability, Maintainability, Reliability

The CMX 600 Vi was meticulously designed to details with a thorough focus on workability from perspective of operators who actually run the machine. Thanks to good access to the spindle and table, operators can smoothly do setup work such as attachment of tools and workpieces. A shallow dent in the front cover also allows them to move one step closer to the table. A big window is used on the front door to drastically improve visibility, which makes it easy for operators to check machining status. Furthermore, the model comes standard with the magazine door to facilitate daily maintenance such as replacement of tools inside the magazine.The CMX 600 Vi boasts high reliability, taking solid measures against chips which are one of the major reasons for machine stop and machining failure. The in-machine cover is tilted at an angle of 30 degrees to prevent chips from accumulating during machining. The ATC shutter also comes as standard to prevent chips from entering the magazine.

Features of CMX 600 Vi are as follows:

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.