Powerful milling with built-in sustainability

By Staff Report December 7, 2024 6:31 pm IST

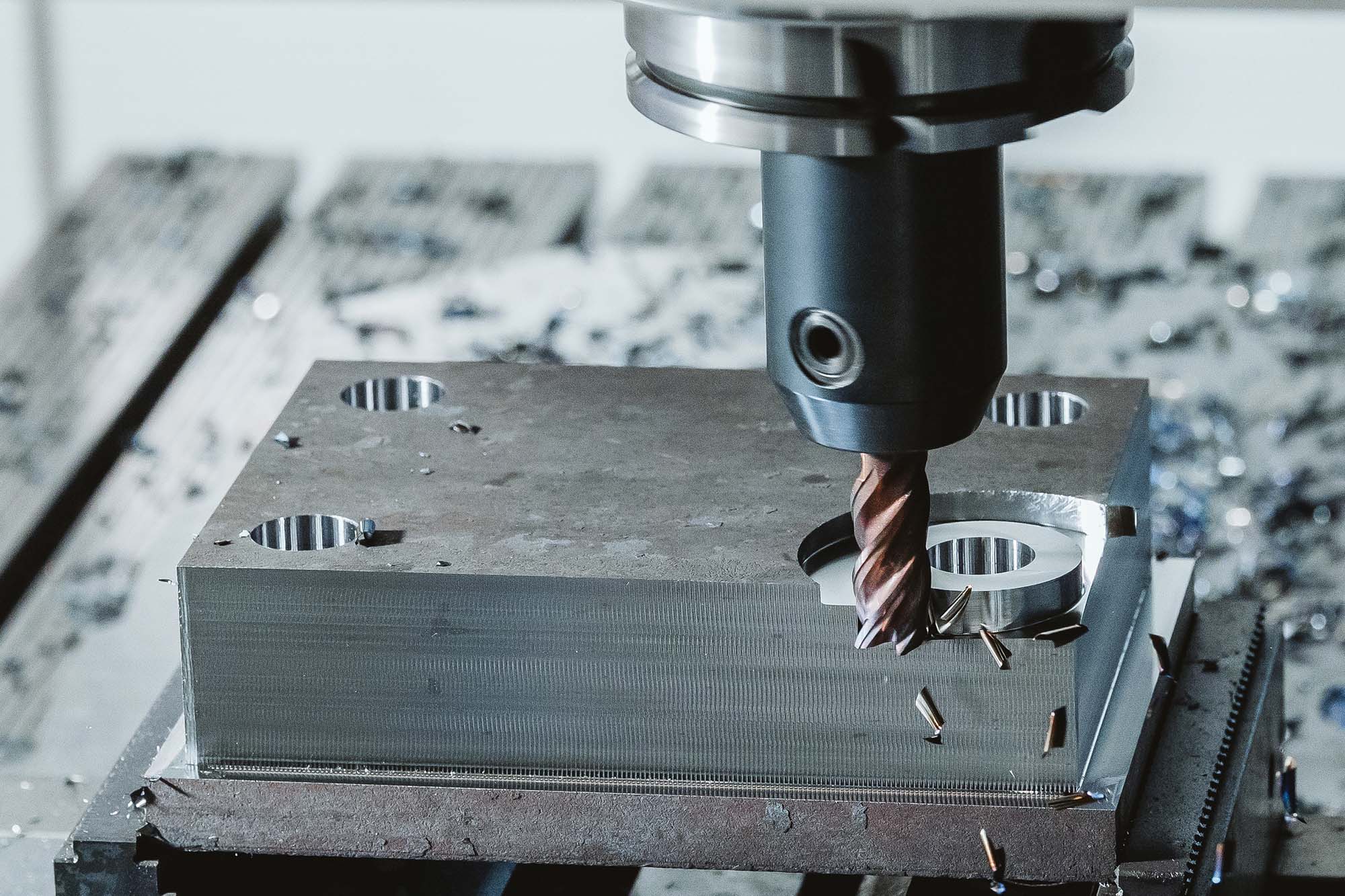

The new S-Cut milling cutters from CERATIZIT, manufactured from 99% reprocessed carbide. A milling cutter that is extremely powerful, universally applicable, and simultaneously manufactured in a resource-efficient manner: with the S-Cut UNI and S-Cut UNImax from CERATIZIT, a tool series is now available that easily meets every requirement. It’s all thanks to the latest geometry and coating technologies combined with carbide grade CT-GS20Y, which offers unbeatable sustainability.

Machining a wide variety of materials means constantly adapting to new challenges. The solution requires universal milling cutters that can cope with steels, stainless steels and cast materials in equal measure. Alongside the targeted process efficiency, sustainability is increasingly growing in importance. CERATIZIT shows how the two objectives can be reconciled – with the new milling cutters from the universal solid carbide milling cutter series S-Cut. The milling cutters are manufactured from a particularly sustainable carbide, which CERATIZIT calls upGRADE.

Full performance from 99% reprocessed raw material

The upGRADE CT-GS20Y grade is the ideal choice for many applications. “What’s special about it is the significantly smaller carbon footprint generated during production than conventional production carbides. This has been achieved using 99% reprocessed cutting tools as a raw material. Customers enjoy economic and ecological advantages due to a specific product’s carbon footprint (PCF).

The new series’ test results underline its potential. The new S-Cut milling cutters deliver up to 30% higher performance compared to other universal tools. The newly developed coating improves performance and tool life.

The new S-Cut UNI and S-Cut UNImax power milling cutters

With the new S-Cut series, CERATIZIT has developed a powerful tool for universal milling, packed with everything modern milling cutters need – including CT-GS20Y, their most sustainable carbide grade. The variable helix pitch ensures extremely quiet running and optimum chip removal. The S-Cut UNI has an HB shank for perfect force transmission, while the reinforced tool core ensures even force distribution throughout the milling process.

The milling cutter has been given a radial clearance face to guarantee cutting-edge stability. The face finishing chamfer promises top surface quality with base machining while cutting edges with an irregular pitch specifically suppresses vibrations. Ramping milling and helical milling are possible up to an angle of 30°. Due to the impressive milling acoustics of the S-Cut UNI (even with high infeed values and full-face milling), the machine room is never too noisy.

With a cutting-edge length of 3xDC, the S-Cut UNI is particularly suitable for series production and trochoidal machining. Innovative chip breakers in a radial design deliver the longest possible tool life and break the chips to a length of 1xD; these are then evenly removed due to the special shape of the chip space. The 5-edge cutter runs quietly even with a high lateral width of cut because of the minimal conical tool core.

The S-Cut UNImax is the ideal solution for maximum material removal. A special geometry design has been selected fo

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.