Blue Star Metrology Solutions: Precision with the new series of 3D scanners

By OEM Update Editorial June 17, 2024 5:53 pm IST

In an era where precision and efficiency are paramount, Blue Star Engineering & Electronics (Blue Star E&E) stands at the forefront of metrology innovation. With a proven track record spanning over a decade, Prem Aruliah John, Business Head – Metrology Solutions, Blue Star E&E, presents their new series of 3D scanners designed to meet the evolving needs of Indian industries.

How does your new 3D scanner series differ from other scanners available?

Blue Star E&E’s new series of 3D scanners represents the latest advancements in metrology equipment. These scanners integrate state-of-the-art laser and optical technology, delivering unparalleled precision and efficiency. Blue light technology has significantly enhanced accuracy, enabling detailed surface inspections and measurements of complex geometries. Our real-time data processing software ensures faster and more reliable results for industries striving for higher productivity and minimal downtime.

The high-resolution 3D scanners, with advanced analysis software, facilitate precise measurement and quality control. This technology enhances the accuracy of inspections while reducing the time required for data processing and analysis. Consequently, operational efficiency is significantly improved, allowing industries to meet stringent quality standards and compete effectively in the global market.

We recognise the diverse metrology challenges faced by various industries. Whether in automotive, aerospace, or manufacturing, each sector has unique requirements. Our new series of 3D scanners is designed to perform in harsh industrial environments, providing reliable measurements even under challenging conditions. This adaptability ensures that industries can scale up their manufacturing processes seamlessly, maintaining high accuracy and consistency.

What other metrology solutions does Blue Star offer beyond portable 3D Scanners?

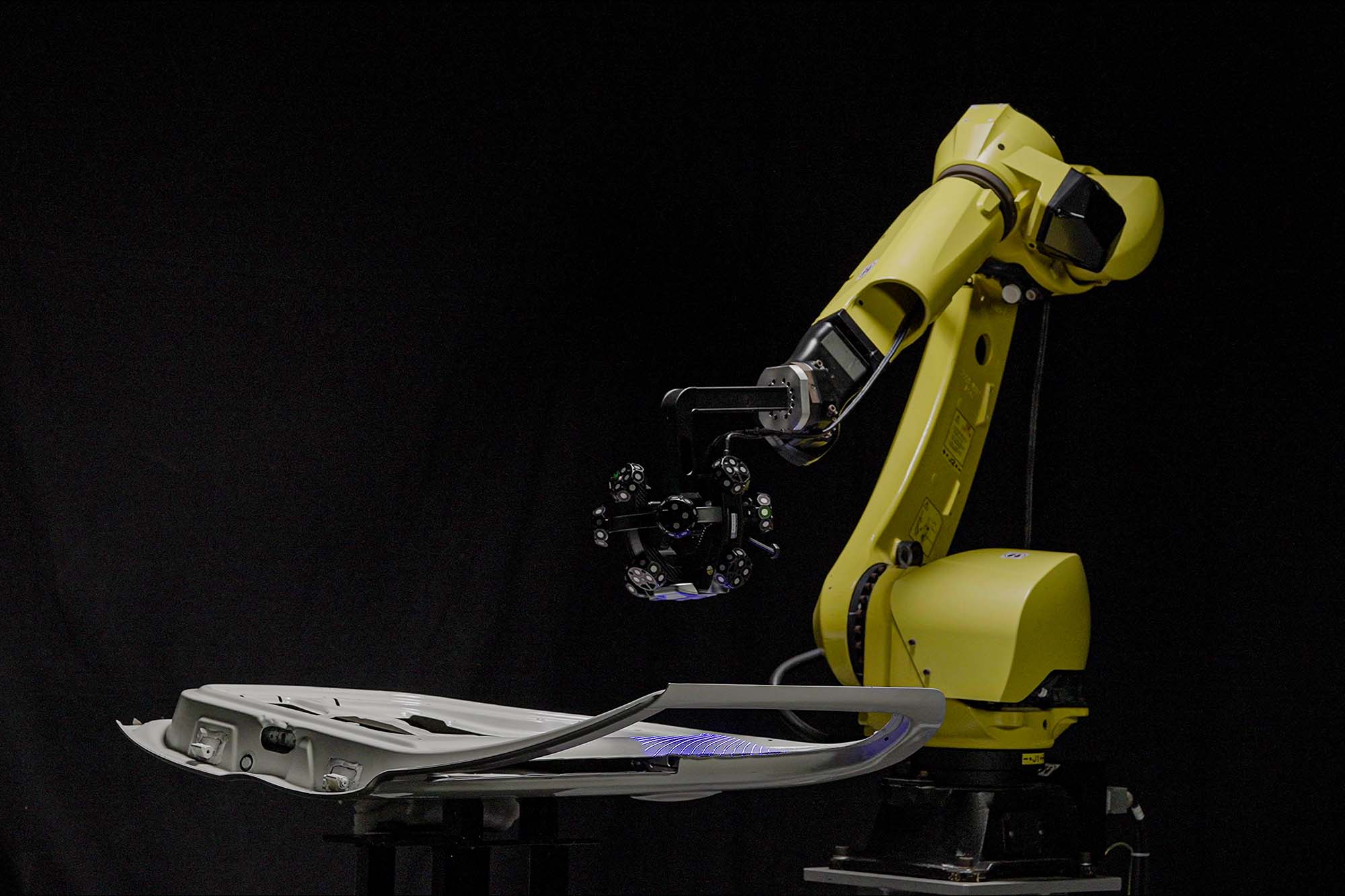

In addition to our range of portable 3D scanners, we offer a Structured Light 3D Scanner, a cutting-edge technology tailored for industrial applications. This advanced system employs structured light patterns to capture high-resolution 3D images of complex objects with exceptional accuracy and speed. Its versatility makes it indispensable for aerospace, automotive, manufacturing, and quality control industries. The scanner’s ability to quickly generate detailed 3D models, inspect components, and ensure precise measurements significantly enhances production efficiency and quality assurance.

Moreover, our Automated Inspection Solutions leverage state-of-the-art sensors and software algorithms to capture and analyse 3D data with unmatched speed and accuracy. These solutions save time and resources while ensuring reliable results, proving ideal for quality control, dimensional analysis, and defect detection. We want users to experience the power of automation and elevate their inspection processes with our comprehensive 3D automated inspection solutions.

Many customers in your line of business have had trouble calibrating the equipment. How do you address this issue?

With over ten years of experience in the 3D scanning market, we understand customers’ inconvenience due to long support times and the need to send equipment away for calibration. To address this, we have established an NABL-accredited facility where we offer calibration services for 3D scanners. This allows customers to have their scanners, regardless of the make, calibrated at our facility with a quick turnaround time and at affordable prices. Additionally, we offer our rent systems for smaller tasks and provide professional metrology services to help customers make informed decisions before investing in their equipment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.