Sustainability initiatives in metal forming with advanced technologies

By OEM Update Editorial December 29, 2023 6:36 pm IST

Niraj Seth, President of Amada (India), while exploring the transformative power of digital integration and robotics in the metalworking landscape, remarks that Amada’s eco-friendly range and cutting-edge tech signal an era of sustainable manufacturing.

How do you envision leveraging the surge in domestic demand within the sheet metal industry?

The Indian economy is currently showing a growth rate of 7.6 percent, as reported by government agencies. Forecasts indicate a promising outlook for the manufacturing sector in the fiscal year 2024. There is a noticeable surge in domestic demand within the sheet metal industry, particularly in the automobile, agriculture, railways, and infrastructure sectors. Companies are keen on expanding their production capabilities, specifically emphasising incorporating automation into their processes.

What innovative strategies does Amada (India) employ to tailor its product range for the aerospace and electric vehicle sectors?

By 2030, India is anticipated to secure the position of the world’s third-largest economy, fostering demand for various products such as advanced automation, cutting-edge welding technology, and innovative press solutions tailored to meet the needs of emerging industries like Aerospace and Electric Vehicles (EVs). This year, alongside our participation in IMTEX Forming, our affiliated company, Amada Weldtech, will exhibit its product range designed for these industries at WeldExpo.

Please elaborate on how the integration of LBC fiber laser technology and specialised bending automation caters to the challenges faced by job shops.

At IMTEX 2024, Amada will introduce its range of ECO products, supporting the Indian sheet metal industry with sustainable manufacturing. We are launching many first technologies like Locus Beam Control (LBC Technology) fiber laser technology. It can process material at higher speeds with the best-cut quality and lower price. Also, we are introducing specialised bending automation designed for job shops, targeting support for manufacturing scenarios with high variability and low volumes. Concurrently, we focus on IoT-driven tools and software to enhance customer productivity.

How are automation solutions contributing to improving efficiency in metal forming procedures?

The sheet metal industry consistently faces challenges due to reliance on skilled labour. Our product line aims to reduce this dependence by offering automation solutions, including robotics. These solutions have gained substantial popularity in advanced nations like Japan and America, while in India, we actively advocate for robotic bending machines and comprehensive automation systems.

How does your transition to 100 percent renewable energy reflect the commitment to achieving carbon neutrality by 2050?

AMADA has achieved a milestone by becoming the initial company in Japan’s machine tool industry to participate in the ‘RE100’ global environmental initiative. The company has transitioned all its power supplies across bases in Japan to rely entirely on renewable energy, marking a significant commitment to sustainability.

‘RE100, which stands for 100 per cent Renewable Energy’, is the global corporate renewable energy initiative that brings together hundreds of large and ambitious businesses committed to 100 per cent renewable electricity.

Here are a few instances of newly introduced eco-friendly products.

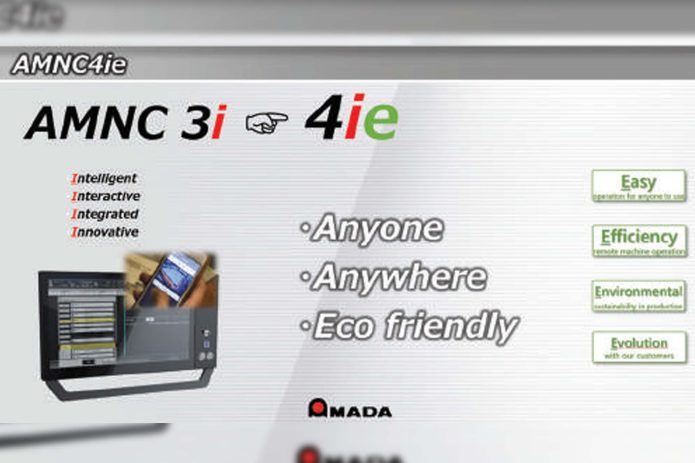

· Machines equipped with the new NC equipment “AMNC 4ie” that includes a display of the CO2 emissions· New fiber laser cutting machines with CO2 emissions reduced by 65 percent (compared with representative products in 2013)

· New press brakes with electric servos that realise an oil-free drive shaft

· Multi-shelf systems for lasers that enable automated production at night.

Since the fiscal year 2022, AMADA has transitioned all electricity consumption across its domestic bases, including works, plants, and sales offices, to rely on 100 per cent on renewable energy exclusively. This represents a reduction of approximately 28,000 tons of greenhouse gas emissions. When other CO2 reduction initiatives and the effects of energy-saving measures are included, this is a 90 per cent reduction in CO2 emissions (Scope 1 + 2) from fiscal 2013 at Japan’s domestic works and plants (and a 65 per cent reduction for all bases, including those overseas).

Based on the Basic Policy on Sustainability, which the AMADA Group established in 2021, the Group has recognised a ‘decarbonised society’ as an important issue that should be addressed. To achieve this goal, the targets set for its works and plants are to aim for a 75 percent reduction in CO2 emissions by fiscal 2030 (compared to fiscal 2013) and carbon neutrality by fiscal 2050.

In line with global initiatives, AMADA backed the Task Force on Climate-related Financial Disclosures in April 202 (TCFD) in April 2022 and obtained SBT (science-based greenhouse gas reduction targets) certification in November of that same year. The AMADA Group is also implementing environmental measures through its products, aiming to reduce CO2 emissions by 50 percent by fiscal 2030 (compared to fiscal 2013). The AMADA Global Innovation Center (AGIC) unveiled in February 2023 highlights cutting-edge products that prioritise environmental sustainability by harnessing advanced technologies.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.