Trends and challenges influence laser cutting and metal forming market growth

By OEM Update Editorial September 3, 2021 1:59 pm IST

Autonomous operations of various machines in future are going to be trend. In 2021 growth of laser cutting machine will have significant change. The global laser cutting machine market size at USD 3455.4 Mn in 2020 will register 8.2% CAGR and reach USD 4738.8 million by 2026.

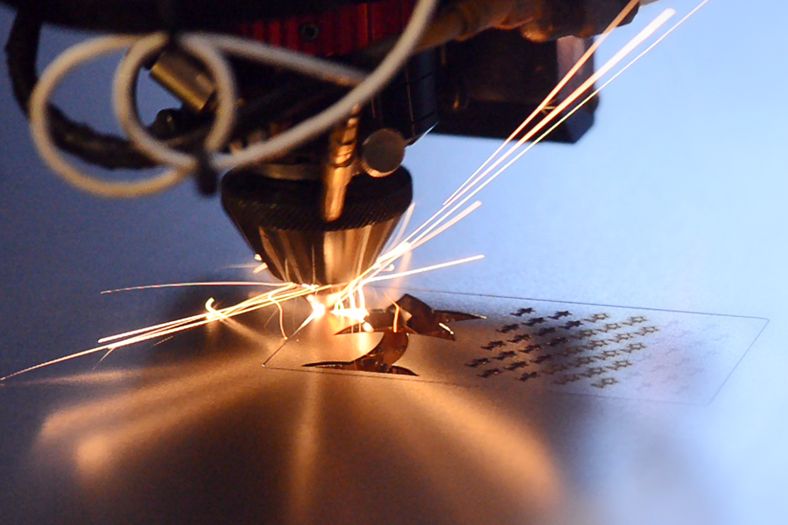

Laser cutting technology – while typically used for industrial manufacturing applications, is now used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The robotic laser cutting market is driven by increased productivity with improved laser technology. Studies indicate, robotic laser cutting market is poised to grow by USD 173.13 million during 2020-2024, progressing at a CAGR of about 17 percent during the forecast period. APAC region, the largest robotic laser cutting market in 2019, will offer several growth opportunities to market.

In the emerging countries, namely, India and China, the rise in the number of industrial activities is resulting in the growing demand for steel fabrication. The global Metal Forming Machine Tools Market size is projected to reach USD 48.67 billion by 2026, exhibiting a CAGR of 5.2 percent. The industries, such as consumer electronics, automotive, and aerospace, are demanding for fabricated metals. Metal fabrication possesses a wide range of applications. Right from office supplies, such as paper clips, to airplane parts, their usage is increasing day by day; fuelling the metal forming machine tools market growth.

Advantages for SME and MSME sectors

Talking about recent enhancement, Seth from Amada India says, update in fibre laser technology has overcome many of the shortcomings of a CO2 based laser which is definitely going to help metal fabrication manufacturers. These fabricators are mostly from SME and MSME sectors. Fibre lasers are very energy efficient and fast. Apart from higher productivity, we can achieve less taper across thickness which eliminates secondary machining process. Fibre laser improves material utilisation and subsequently reduces cost of production.

Talking about updated technologies, Mukherji from Messer Cutting System stressed, SME and MSME to have updated technologies in their field of operations because helps to be more productive; better control on cost and quality and helpful for fetching new orders.

Manjrekar from Bystronic Laser India, elaborates upon latest offering, and mentions that there is tremendous potential for the large format laser with bigger table size and higher laser power like 10 KW and above in Indian Market. Machine tools segment demands quick approach in estimation with precise detailing, having better technological edge by means of the software and the efficient machine will enhance their chances to encash more business. The key is to map out your present factory capacity and align your production to the best of equipment efficiency. Better technology not only helps to increase the throughput but also reduce the down time with advance diagnostic and troubleshooting analysing capability of the Machine controller. He remarks, in the present scenario, contribution of the SME and the MSME is very critical and they consume the large share of the machine tools from the total sales. To be competent and agile they have to invest in the technology and solutions which can drive their business towards better throughput and faster ROI. He adds, “Need for basic automation has increased.”

Technologies enhancing metal forming & laser cutting

The high-technology company TRUMPF offers production solutions in the machine tool and laser sectors. JBM is working with various car manufacturers. Gupta President Strategy & Business Planning of JBM Auto Components, says, “We produce components for all international vehicle manufacturers that have a presence in India.” These include companies such as Daimler, Ford and Suzuki-Maruti. Also, “The demand for lightweight automotive components is growing rapidly,” It is no coincidence that JBM relies on TRUMPF for processing the high-strength steels.

Robotic laser cuttingFurther to say, the familiar blue cobots of Ann Arbor’s Universal Robots will be featured in more than 20 booths, including its own, at the FABTECH 2021 trade show at McCormick Place in Chicago September 13-16. The usage of robotic laser cutting in the aerospace and defines industry is one of the critical robotic lasers cutting market trends likely to influence the market positively in the years to come. Growing aircraft demand and the presence of a large existing base of manufacturing facilities will significantly influence and lead the robotic laser cutting market. The governments of various countries are taking construction initiatives that would also boost the market growth.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.