Shaping up machining and sheet metal process with CNC

By OEM Update Editorial May 4, 2021 12:00 pm IST

This article analyses the numerous factors driving the growth of the CNC machine tools for sheet metal, along with the technological and business aspects for the sector’s renewed growth.

The global CNC Machine Tools market is expected to reach $117.65 Bn by 2027. Because, the increasing advancements in product technology have reduced the time to manufacture components.

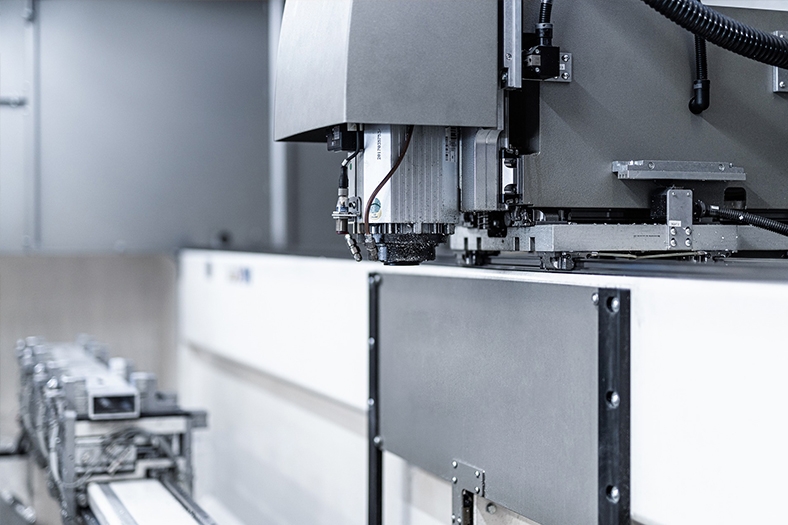

The CNC metal cutting machine tools are gaining traction in India. This is mainly because of the increase in demand for timely delivery, accuracy, and energy efficiency in the metal fabrication industry. Moreover, rising demand for electromechanical machining is directing us towards the growth of machine tools segment.

Interestingly, according to industrial assumptions, increase in demand for optimal performance and high precision and control is expected to expand the sheet metal forming sector in the coming years.

Major growth drivers of CNC market

With the Internet of Things (IoT) leading the indomitable march of Industry 4.0, it is no surprise that CNC machining is dominating the lathing, milling, and grinding sectors. Moreover, growth in smart factories powered by artificial intelligence systems will boost the uptake of CNC machines. The demand for these machines will intensify further as they will lower the machining time and labour cost and increase productivity. Lastly, the advent of Industry 4.0 will further accelerate the CNC machine market growth.

According to Nilesh Chandhad, Director, Chanchad Machine Tools Pvt. Ltd., “CNC Machines hold a significant role in sheet metal forming applications. With the help of CNC, you can reap advantages of repeatability of job very easily. You can also set the features like correction factor through the control unit. It is very ease to make corrections and rework on your forming application with the help of control unit. It further allows you to control pressure / force requirement as per your application’s requirement and not by giving entire load on the application every time. It can be easily programmed to operate machines with the help of CNC much more than from the conventional type machines Instead of conventional type machine. Ease of operation, better accuracy, better repeatability, saving of energy, etc are advantages of CNC machines in metal forming application.

Rajesh Nath, Managing Director, German Engineering Federation (VDMA) explains us, “Growth of CNC machine tools market is fuelled with increased demand from the automotive, aerospace and defence, power and energy, construction equipment, industrial, and several other largescale manufacturing plants. Moreover, increase in expenses of employing operators for individual machinery will further intensify the demand for automated CNC machines.”

According to Vineet Seth, Managing Director – South Asia & Middle East, Mastercam APAC, further, “Growing technological advancements in the medical field also make this industry one of the top proponents of growth for the CNC market. The die and mould market, as a subgroup of all these aforementioned sectors, keep pushing the CNC market to innovate and provide newer technologies to assist complex manufacturing techniques.”

Challenges in CNC machine tools and sheet metal

Challenges in CNC machine tools and sheet metal

Indian manufacturers have always faced challenges in the growth of the CNC market especially pertaining to large costs and lack of skilled and trained manpower for CNC machine tools, forming and fabrication industry.

CNC machines are usually manufactured with high accuracy. Its entire parts, top beams, tables, side frames all these tools should be accurate and perfectly made. Also, the sensors, servo valves must be branded have great quality with a better control unit. Moreover, the designed machines should be able to bear the entire load without any deflection.

Secondly, large costs associated with purchasing new machines and their maintenance further restrict the market’s growth. Also, there’s an impending requirement need to more trained manpower to operate, handle and maintain these machines.

Noting the same, Nath explains that the manufacturers have to spend significantly higher amount towards the maintenance programmes, especially during unexpected breakdowns. Such factors further reduce the growth speed to a great extent, this in return reduce the market growth, and makes the end product costly and dearer.”

Seth says, “Manufacturing growth of the nation, as a factor of GDP, limited manufacturing exports, and the large imports of advanced technological products are the main inhibitors of CNC market growth in our country.”

Future of CNCSeth adds to the discussion by saying, “Promoting the Make in India movement, innovating in technologies that benefit MSMEs, offering competitive pricing, investing in customer education and upskilling are some of the suggestions for driving growth in this segment.”

Technologies like thermal expansion algorithms are going to be critical technological changes in CNC manufacturing, which help to predict when a tool is out of tolerance. Nath explains, “In present CNC machines, the operator has to check whether the tool is worn out or not. But this thermal expansion algorithm would eliminate this manual check by the operator, which could lead to reduction of cycle time and improve the quality of product.”

The technological advancement in CNC machines could evolve the future market in the automobile and aerospace industries by manufacturing high-precision products, which would be the topmost priority in the manufacturing sector.

Shaping CNC machine tools sector

Automation will help for handling and ease of operation. Automation helps to achieve better accuracy and reduce probability of human error. Artificial intelligence is also very important for getting better results and accuracy. We are not using AI in our CNC Machine for metal forming application.

It is pandemic scenario but everyone has to survive in this situation also. We are focusing mainly segment where there is still possibility. Government projects defence and railway sector is important. We follow digital and online marketing and provide services by online as much as possible. We are taking challenging job in this pandemic to survive ourselves.

——-

Rajesh Nath, Managing Director, German Engineering Federation (VDMA), ‘’The industry keeps pushing the CNC market to innovate and provide newer technologies to assist complex manufacturing techniques.’’

—

Vineet Seth, Managing Director – South Asia & Middle East, Mastercam APAC, ‘’Large imports of advanced technological products are the main inhibitors of CNC market growth in our country.’’

—

Nilesh Chandhad, Director, Chanchad Machine Tools Pvt. Ltd, “AI and automation are essential to obtain better and accurate results in sheet machining and forming processes.’’

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.