Productivity enhancement with IIoT

By OEM Update Editorial June 12, 2018 6:00 pm IST

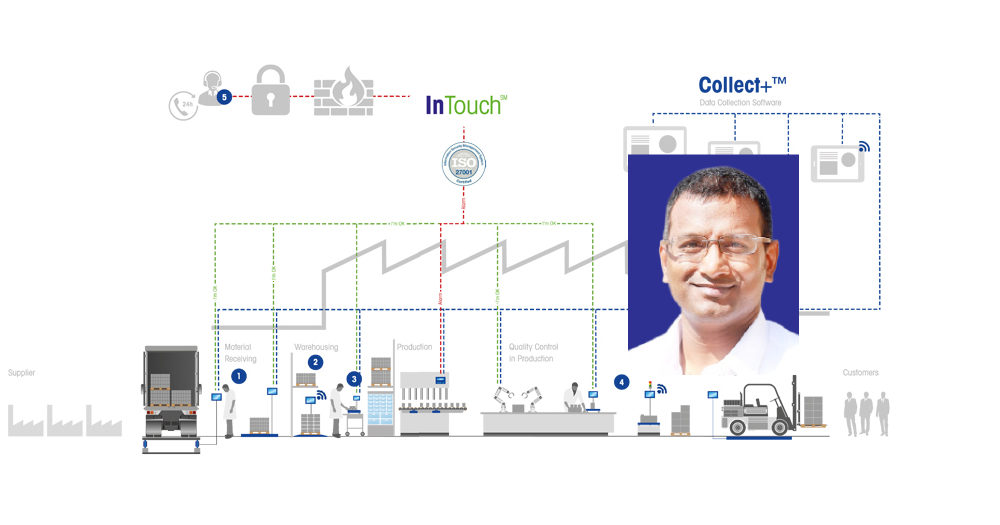

Rajashekar Venkat, GM – Industrial, PI, SCM & Manufacturing, Mettler-Toledo India explains how IIoT will unleash potential of weighing equipment segment.

Recent developments surrounding the Industrial Internet of Things (IIoT) are facilitating a major paradigm shift in manufacturing. Traditional production hierarchy, with centralised control, is shifting towards a decentralised self-organisation, in which the product independently communicates with the production devices and actively intervenes in the production process.

Digitalisation of weighing equipment

As measuring technologies evolve, digitisation has become a core element of innovation. As a result, an intelligent measuring device or sensor provides more than just accurate measuring values. In addition, they can provide qualified real-time status information about the manufacturing process, collect measuring results and steer production equipment. Measuring devices such as weigh modules, platforms and terminals, can be built into highly modular assembly lines and conveyor belts. There they can be either automated or operated manually. Despite increasing automation, manual work will not disappear in modern factories. Assembly, quality checks and material handling are still done by operators on manual workplaces.

Manufacturers are now looking for equipment that allow them to integrate these workstations into their systems. On the operational side, innovative interfaces, user guidance and intuitive handling features can enable productivity potential in factories today.

IIoT and various workplaces

Not only automated production lines benefit from IIoT, manual workplaces also can increase productivity when they can overcome the challenges of the novel interaction between people, machines and data. Workers have to manage faster processes, a higher degree of digitalisation and a greater variety of applications. In addition, they have to deliver continually high quality while product customisation increases. That is why it is important to bring together efficiency, ergonomics and data integration.

1) Intelligent logistics

Start production supervision at your factory gates. Review the deliveries from your suppliers with measuring equipment such as floor and bench scales. Floor scales can count bulk shipments of parts and components whilst compact scales apply when receiving small or valuable material. Weighing devices feed weighing results to your network and prevent over- or out-of-stock situations.

2) Use warehouse entry to gather data

Use bench scales in warehousing to perform picking tasks, cycle counts and prepare exact deliveries for intra logistics. Get orders from your ERP systems and send back the results of your operation. Weighing terminals feature advanced human-interface functions such as user prompting, for error-free handling and speedy processing.

Reduce waste and quality cases with innovative piece-counting and quality check solutions. Scale management software saves all article records and makes recalling article data error-free and fast. Together with the colorWeight result indication this speed-up quality checks even if the product variety increases significantly.

4) Monitor production flow and worker efficiency in real time

Collect+ software captures production-weight and process data from every scale on a shopfloor and visualises it in an easy to understand dashboard. Use data for audits, quality initiatives and process optimisation.

5) Preventative maintenance with remote equipment monitoring

Cloud-based remote monitoring of weigh modules, load cells and scales prevents downtime. Remote support facilitates fast repairs and reduces the need for on-site interventions. All data transfer is protected with third-party accredited security measures.

Authored by:

Rajashekar Venkat,

GM – Industrial, PI, SCM & Manufacturing, Mettler-Toledo India

Mettler-Toledo India Pvt Ltd

Toll free: 1800 22 8884, 1800 1028460

Email: sales.mtin@mt.com

Website: www.mt.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.